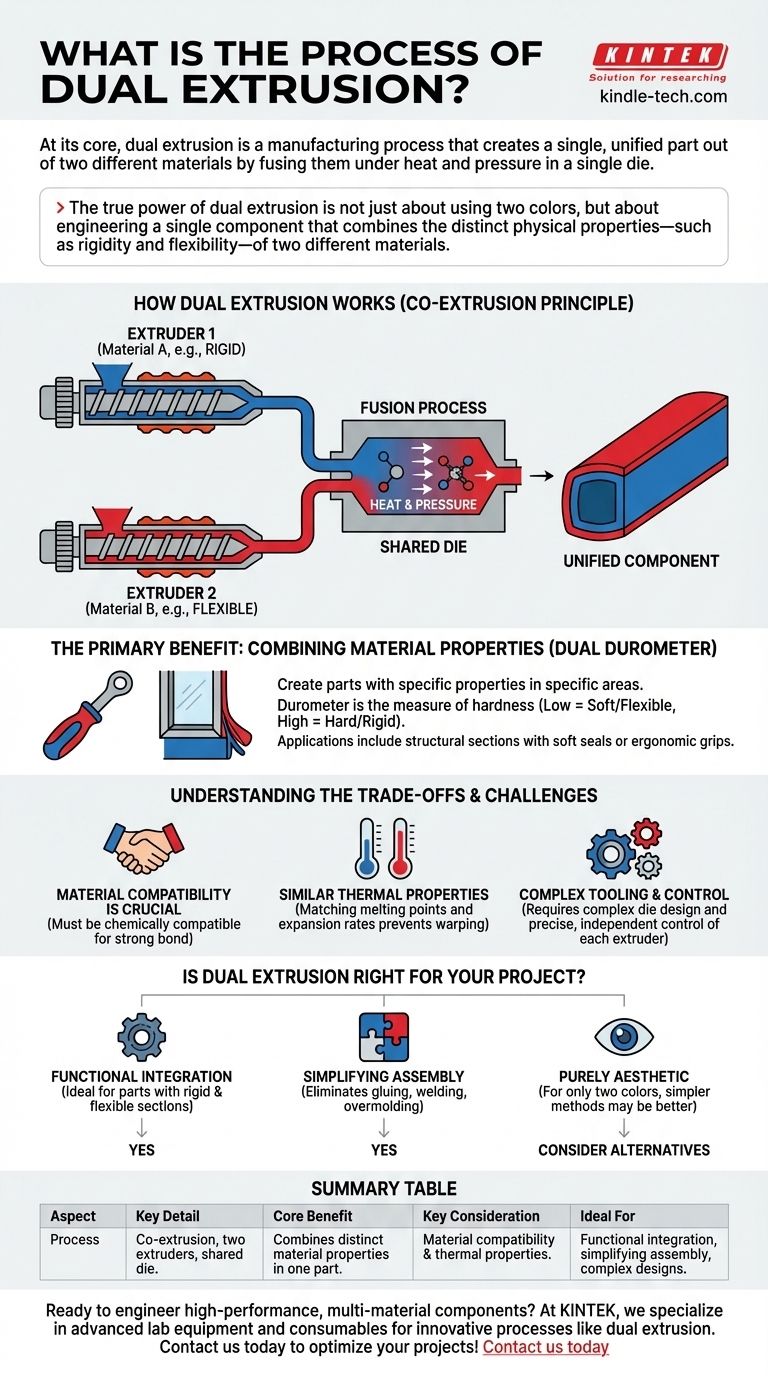

At its core, dual extrusion is a manufacturing process that creates a single, unified part out of two different materials. It achieves this by feeding two distinct materials through separate extruders into a single die at the same time, where they are fused together under heat and pressure.

The true power of dual extrusion is not just about using two colors, but about engineering a single component that combines the distinct physical properties—such as rigidity and flexibility—of two different materials.

How Dual Extrusion Works

Dual extrusion is a sophisticated form of a broader process known as co-extrusion. Understanding the mechanics reveals why it is so effective for creating complex parts.

The Principle of Co-extrusion

The process involves two or more extruders, each dedicated to a specific material. These machines heat and push their respective materials forward.

The Shared Die

The critical element is the shared die. Molten materials from both extruders are forced into this single, specially designed tool simultaneously.

The Fusion Process

Inside the die, the materials merge under precise heat and pressure. This forms a molecular bond between them, creating a single, continuous profile rather than two separate pieces that are simply joined together.

The Primary Benefit: Combining Material Properties

The most significant advantage of this process is the ability to create parts with specific properties in specific areas. This is often referenced as dual durometer extrusion.

Understanding "Durometer"

Durometer is the standard measure of a material's hardness. A low durometer indicates a soft, flexible material, while a high durometer signifies a hard, rigid one.

Practical Applications

This allows for the creation of a part with both a rigid structural section and a soft, flexible sealing or gripping section. Think of a window seal with a hard base to clip into a frame and a soft flap to block air, or a tool handle with a rigid core and a soft, ergonomic grip.

Understanding the Trade-offs and Challenges

While powerful, dual extrusion is a complex process with specific requirements that must be carefully managed for success.

Material Compatibility is Crucial

The two materials must be chemically compatible to ensure a strong, permanent bond. If they are not, the part can delaminate or fail at the seam.

Similar Thermal Properties

Materials must also have similar melting temperatures and rates of thermal expansion. Mismatched properties can cause the part to warp or distort as it cools.

Complex Tooling and Control

The design of a co-extrusion die is significantly more complex and costly than a single-material die. The process also requires precise, independent control over the temperature and pressure of each extruder.

Is Dual Extrusion Right for Your Project?

To determine if this process is the correct choice, consider the fundamental goal of your component.

- If your primary focus is functional integration: Dual extrusion is ideal for creating a single part with both rigid and flexible sections, such as a combination seal and mounting clip.

- If your primary focus is simplifying assembly: This process can eliminate the need for secondary steps like gluing, welding, or overmolding two separate components, reducing labor and potential points of failure.

- If your primary focus is purely aesthetic: For parts that only require two colors without different physical properties, simpler and more cost-effective manufacturing methods may be a better fit.

Ultimately, dual extrusion empowers engineers to create highly integrated, single-piece solutions for complex design challenges.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | Co-extrusion using two extruders and a shared die. |

| Core Benefit | Combines distinct material properties (e.g., rigid & flexible) in one part. |

| Key Consideration | Material compatibility and similar thermal properties are critical. |

| Ideal For | Functional integration, simplifying assembly, and complex component design. |

Ready to engineer high-performance, multi-material components?

At KINTEK, we specialize in providing advanced lab equipment and consumables that support innovative manufacturing processes like dual extrusion. Whether you're in R&D or production, our solutions help you achieve precise material testing and processing for superior results.

Contact us today to discuss how KINTEK can support your laboratory needs and help you optimize your dual extrusion projects!

Visual Guide

Related Products

- CVD Diamond Domes for Industrial and Scientific Applications

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Custom CVD Diamond Coating for Lab Applications

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

People Also Ask

- What is the difference between single layer film and multi layer film? A Guide to Material Selection

- What is a two roll mill? Master Polymer Mixing for R&D and Quality Control

- What is a two-high roll mill? Master Precise Material Compounding and Testing

- What are natural rubber sheets used for? Unlock Durability, Elasticity, and Vibration Damping

- What is an internal mixer? A Guide to High-Volume Rubber & Plastic Compounding

- What does a two roll mill machine do? Master Polymer & Rubber Compounding

- Why is the dynamic mixing mode necessary for high-strength HPE-CSPE? Unlock Superior Elastomer Performance

- What is a laboratory mixer used for? Choose the Right Tool for Liquids or Solids