The fundamental purpose of using argon gas in sputtering is to create ions. These ions act as projectiles in a high-energy "sandblasting" process, bombarding a target material and physically knocking its atoms loose so they can deposit as a thin film onto a substrate.

Sputtering is not a chemical or thermal process; it is a physical momentum transfer. Argon is chosen as the ideal "sand" for this atomic-scale sandblasting because it is chemically inert and has the right mass to efficiently eject atoms from the target without contaminating the resulting film.

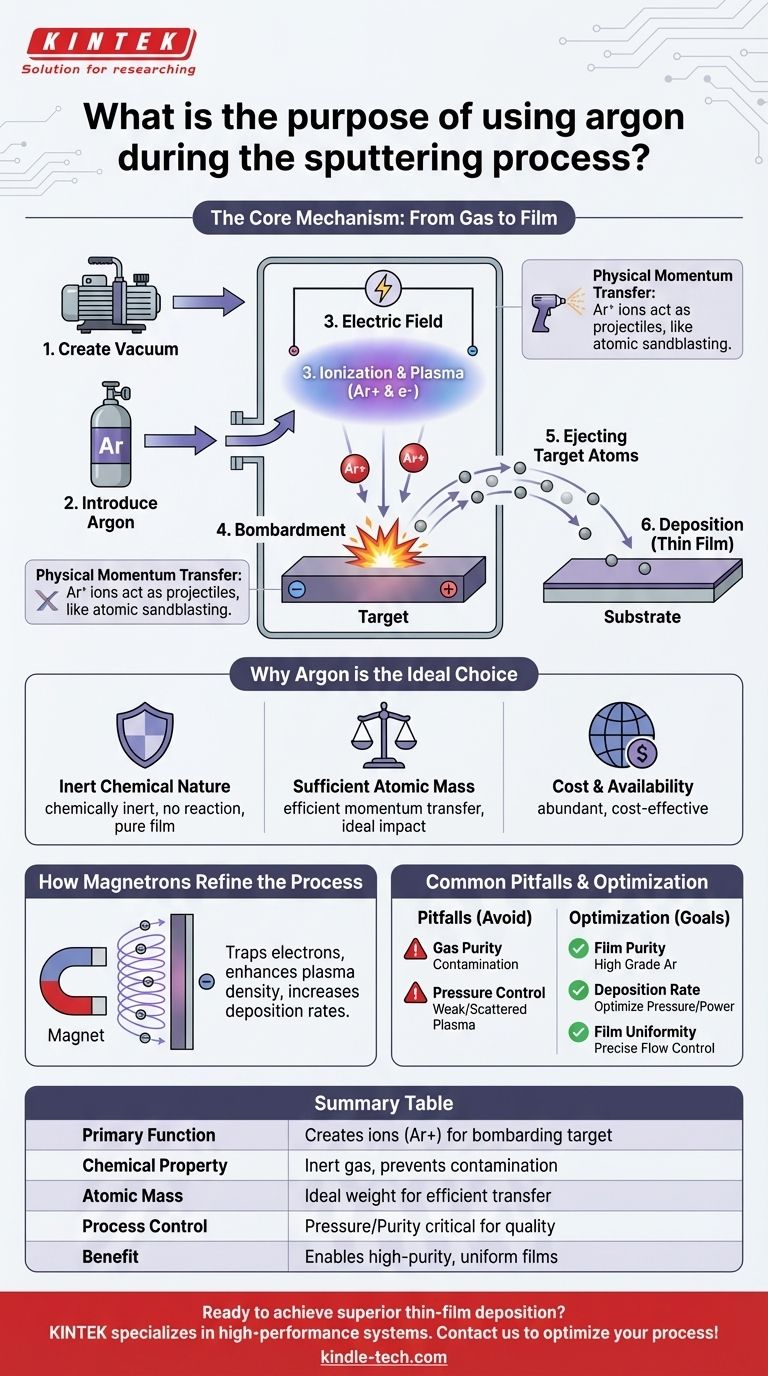

The Core Mechanism: From Gas to Film

To understand the role of argon, you must first understand the sputtering process itself. It's a precise, multi-step chain of events that occurs within a vacuum chamber.

Creating the Plasma Environment

First, the sputtering chamber is pumped down to a high vacuum to remove any unwanted atmospheric gases. Then, a small, precisely controlled amount of high-purity argon gas is introduced.

The Role of Ionization

A strong electric field is applied within the chamber. This field energizes the argon gas, stripping electrons from the argon atoms and creating a mixture of positively charged argon ions (Ar+) and free electrons. This energized, ionized gas is known as plasma.

Bombarding the Target

The material to be deposited, known as the target, is given a negative electrical charge. The positively charged argon ions in the plasma are naturally and forcefully accelerated toward this negatively charged target.

Ejecting the Target Material

The high-energy argon ions collide with the surface of the target. This impact has enough force to physically knock atoms of the target material loose, a process called sputtering. These ejected target atoms then travel through the chamber and coat the nearby substrate, forming a thin, uniform film.

Why Argon is the Ideal Choice

While other gases can be used, argon is the industry standard for most sputtering applications for several key reasons.

Inert Chemical Nature

Argon is a noble gas, meaning it is chemically inert. It will not react with the target material, the substrate, or the chamber components. This ensures that the final deposited film is pure and has the exact properties of the original target material.

Sufficient Atomic Mass

Argon has an ideal atomic mass for this process. It is heavy enough to efficiently transfer momentum and dislodge atoms from most common target materials. Lighter gases might not have enough impact, while significantly heavier gases could become embedded in the film or damage the substrate.

Cost and Availability

Argon is the third-most abundant gas in Earth's atmosphere, making it readily available and cost-effective for large-scale industrial manufacturing processes.

How Magnetrons Refine the Process

Simply creating an argon plasma is not enough for modern applications. Magnetrons are used to dramatically improve the efficiency of the process.

Trapping Electrons, Enhancing Plasma

Powerful magnets are placed behind the target. This magnetic field traps the free electrons from the plasma, forcing them into a spiral path near the target's surface.

Increasing Ionization Efficiency

These trapped electrons are far more likely to collide with neutral argon atoms. Each collision creates another argon ion, dramatically increasing the density and intensity of the plasma directly in front of the target where it is most needed.

Improving Deposition Rates

A denser plasma means more argon ions are available to bombard the target. This results in more sputtered atoms and a significantly faster, more efficient, and more controllable deposition rate.

Common Pitfalls to Avoid

The role of argon seems straightforward, but its management is critical for achieving a high-quality result.

Gas Purity is Critical

Any impurities in the argon gas, such as oxygen or water vapor, can react with the target material. This creates unwanted compounds and contaminates the final film, altering its electrical, optical, or mechanical properties.

Pressure Control is Essential

The pressure of the argon gas inside the chamber is a critical variable. Too little pressure results in a weak plasma and a very slow deposition rate. Too much pressure can cause the sputtered atoms to collide with argon atoms on their way to the substrate, scattering them and reducing film quality and uniformity.

Making the Right Choice for Your Goal

Controlling the argon gas is central to controlling the outcome of the sputtering process.

- If your primary focus is film purity: Use the highest grade of argon gas available (UHP 99.999%) and ensure your vacuum chamber has no leaks.

- If your primary focus is a high deposition rate: You must optimize the argon pressure in conjunction with the magnetron power to create the densest, most stable plasma possible.

- If your primary focus is film uniformity: You need precise control over the argon gas flow and pressure to ensure the plasma density is consistent across the entire surface of the target.

Ultimately, argon is the indispensable tool that transforms a solid source material into the atomic vapor required for high-performance thin-film deposition.

Summary Table:

| Key Aspect | Role of Argon in Sputtering |

|---|---|

| Primary Function | Creates ions (Ar+) for bombarding the target material |

| Chemical Property | Inert gas, preventing contamination of the film |

| Atomic Mass | Ideal weight for efficient momentum transfer |

| Process Control | Gas pressure and purity are critical for film quality and deposition rate |

| Benefit | Enables high-purity, uniform thin-film deposition for electronics, optics, and more |

Ready to achieve superior thin-film deposition in your lab? The precise control of argon gas is just one part of the equation. KINTEK specializes in high-performance sputtering systems and consumables, ensuring optimal plasma conditions for your specific materials and applications. Let our experts help you optimize your process for maximum purity, uniformity, and deposition rate. Contact KINTEK today to discuss your laboratory's thin-film needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What is ethylene cracking furnace? The High-Temperature Heart of Petrochemical Production

- What are the uses of sintering? Unlock Manufacturing for High-Temp Materials

- What is furnace soldering? A High-Volume Process for Joining Components

- Is biomass renewable or non renewable energy? The Truth About Sustainable Power

- What is a sputtering machine? A Guide to High-Quality Thin Film Deposition

- What is the efficiency of plastic pyrolysis? A Deep Dive into Mass Yield, Energy Balance, and Economic Viability

- What are the safety precautions for forging? A Complete Guide to Protecting Against Heat, Force, and Fumes

- Why pyrolysis is better than incineration? Transforming Waste into Valuable Resources