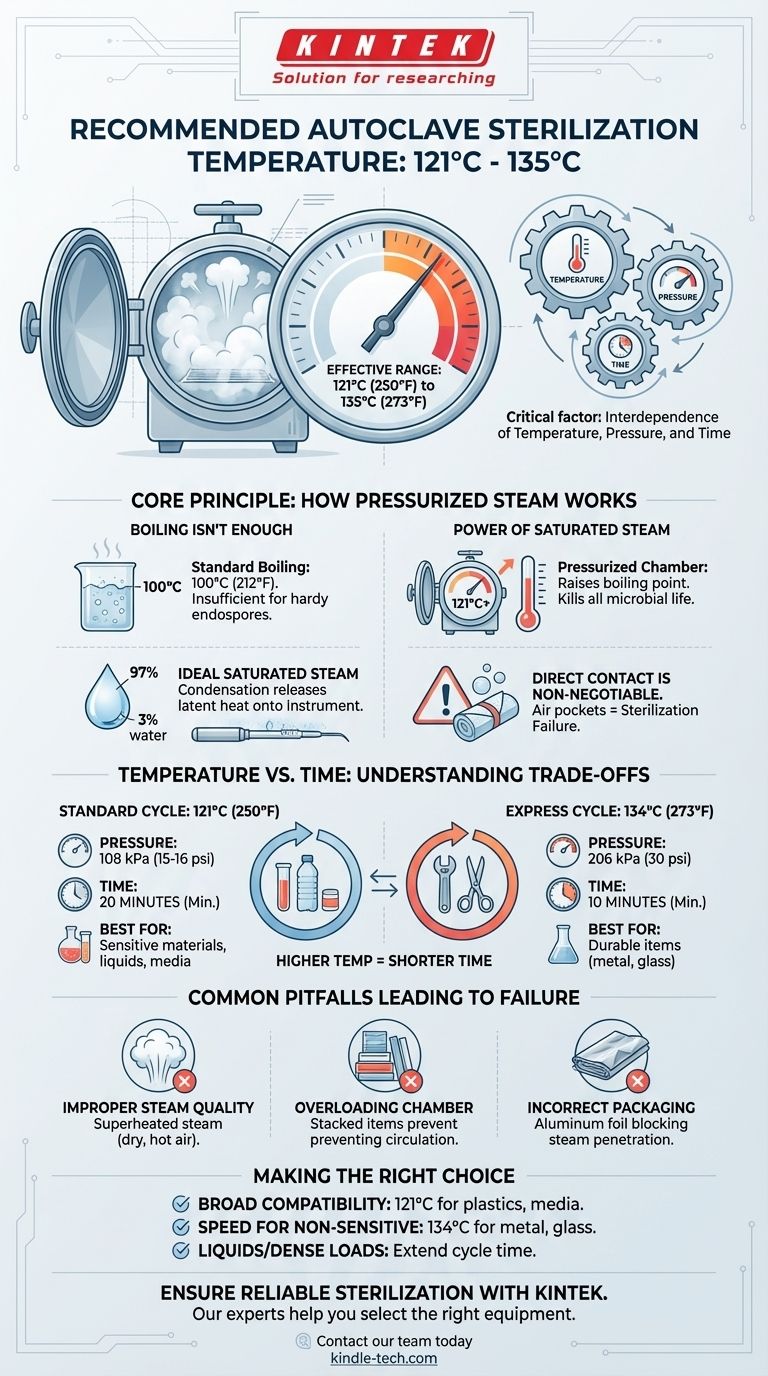

For effective steam sterilization, the recommended temperature in an autoclave is between 121°C (250°F) and 135°C (273°F). This temperature is achieved by using highly pressurized steam, which is essential for destroying heat-resistant microorganisms, including bacterial endospores. The specific temperature you choose directly impacts the required exposure time.

The critical factor for successful autoclaving is not just reaching a specific temperature, but understanding the interdependent relationship between temperature, pressure, and time. Higher temperatures allow for significantly shorter sterilization cycles, but the steam must make direct contact with all surfaces to be effective.

The Core Principle: How Pressurized Steam Works

An autoclave's effectiveness comes from its ability to harness the physical properties of water under pressure. This process is far more efficient than simply boiling items in water.

Why Standard Boiling Isn't Enough

Standard boiling water at sea level reaches only 100°C (212°F), which is insufficient to reliably kill hardy bacterial endospores. By pressurizing the chamber, an autoclave raises the boiling point of water, allowing the steam to reach temperatures of 121°C or higher, ensuring the destruction of all microbial life.

The Power of Saturated Steam

The key to sterilization is saturated steam, which the references suggest should ideally be a mixture of 97% steam and 3% moisture. When this precisely balanced steam hits the cooler items in the chamber, it rapidly condenses. This phase change releases a massive amount of latent heat, which quickly denatures the essential proteins of microorganisms.

Direct Contact is Non-Negotiable

For the heat transfer to occur, steam must physically touch every surface of the items being sterilized. If air is trapped in the chamber or items are improperly wrapped or packed, it creates insulating air pockets that prevent steam contact, leading to sterilization failure.

Understanding the Trade-offs: Temperature vs. Time

The relationship between temperature and time is inversely proportional. Choosing the correct cycle involves balancing the need for speed against the heat sensitivity of the materials being processed.

The Standard Cycle: 121°C (250°F)

This is the most common and widely validated sterilization cycle. At 121°C, under approximately 108 kPa (15-16 psi) of pressure, a typical cycle requires at least 20 minutes of exposure time. This longer, lower-temperature cycle is gentler on more sensitive materials.

The Express Cycle: 134°C (273°F)

For robust materials like unwrapped metal instruments, a higher temperature can dramatically increase efficiency. At 134°C, achieved with a higher pressure of around 206 kPa (30 psi), the required sterilization time can be reduced to as little as 10 minutes.

Common Pitfalls That Lead to Sterilization Failure

Achieving the correct temperature is only part of the equation. Several common operational errors can render the entire process ineffective.

Improper Steam Quality

If the steam contains less than 3% moisture, it becomes superheated (dry) steam. This type of steam is a poor agent for sterilization because it transfers heat much less efficiently than saturated steam, behaving more like hot air.

Overloading the Chamber

Placing too many items in the autoclave or packing them too densely prevents proper steam circulation. This creates cool spots where items are not fully exposed to the steam, leaving them unsterilized.

Using Incorrect Packaging

Wrapping instruments in materials that are impermeable to steam, such as aluminum foil, or using excessive layers of cloth wrap will block sterilization. Always use approved autoclave pouches or wraps that allow for steam penetration.

Making the Right Choice for Your Application

Selecting the appropriate cycle depends entirely on the items you are sterilizing and your operational needs. Use these guidelines to make an informed decision.

- If your primary focus is broad material compatibility: The standard 121°C cycle is the safest choice, as it is less likely to degrade plastics, media, or other heat-sensitive items.

- If your primary focus is speed for non-sensitive items: The 134°C cycle provides a significant time advantage for sterilizing durable metal or glass goods.

- If you are sterilizing liquids or dense loads: You must extend the cycle time—regardless of temperature—to ensure the core of the load reaches the target temperature for the required duration.

Ultimately, understanding these core principles is the key to ensuring complete and reliable sterilization every time.

Summary Table:

| Temperature | Typical Pressure | Minimum Exposure Time | Best For |

|---|---|---|---|

| 121°C (250°F) | 108 kPa (15-16 psi) | 20 minutes | Gentle on sensitive materials, liquids, media |

| 134°C (273°F) | 206 kPa (30 psi) | 10 minutes | Fast sterilization of durable items (metal, glass) |

Ensure your lab's sterilization is reliable and efficient. KINTEK specializes in high-performance autoclaves and lab equipment designed to meet the precise demands of sterilization protocols. Our experts can help you select the right equipment to achieve perfect steam quality, optimal temperature control, and complete sterilization cycles. Contact our team today to discuss your laboratory's specific needs and enhance your sterilization processes with KINTEK's trusted solutions.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What does an autoclave kill? Achieve Complete Sterilization for Your Lab

- What is the role of high-pressure high-level autoclaves in simulating 9Cr–1Mo steel reactions? Expert Insights

- How does an industrial autoclave work? Unlock the Power of High-Pressure Steam for Sterilization

- What does the autoclaving process involve? Master the 3 Phases for Reliable Sterilization

- Why do we do 121 degree sterilization? The Science Behind Guaranteed Sterility

- How does an autoclave work in simple words? Sterilize with High-Pressure Steam

- What is the primary function of a laboratory Autoclave in seaweed hydrolysates? Sterilize and Optimize Fermentation

- Why is a high-pressure steam sterilizer or autoclave required during the biomass pretreatment process? Optimize Yields