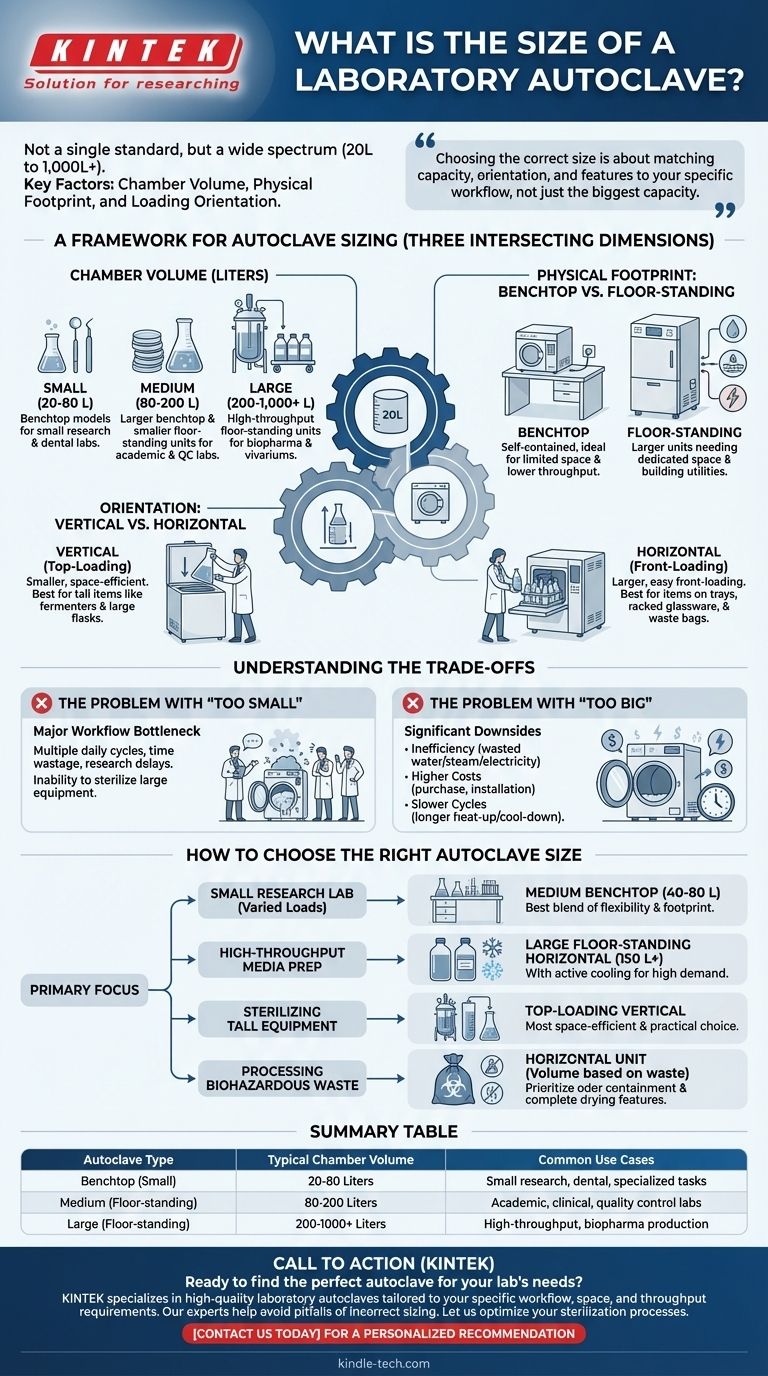

The size of a laboratory autoclave is not a single standard but spans a wide spectrum, from compact benchtop units with a capacity of around 20 liters to large, industrial-scale chambers exceeding 1,000 liters. The most common sizes are categorized by their internal chamber volume, physical footprint (benchtop vs. floor-standing), and loading orientation (vertical vs. horizontal).

Choosing the correct autoclave size is less about finding the biggest unit you can afford and more about strategically matching the chamber's capacity, orientation, and features to your lab's specific workflow, load type, and available space.

A Framework for Autoclave Sizing

"Size" in the context of an autoclave is a multi-dimensional concept. Understanding each dimension is critical to making an informed decision that supports your lab's efficiency rather than hindering it.

Chamber Volume (Liters)

The most fundamental measure of an autoclave's size is its internal chamber volume, measured in liters (L). This directly dictates how much material you can sterilize in a single cycle.

- Small (20-80 L): These are typically benchtop models found in small research labs, dental offices, or for specialized tasks.

- Medium (80-200 L): This range includes larger benchtop units and smaller floor-standing models. They are workhorses for many academic, clinical, and quality control labs.

- Large (200-1,000+ L): These are large, floor-standing horizontal autoclaves used in high-throughput environments like vivariums, biopharmaceutical production, and central sterile supply departments.

Physical Footprint: Benchtop vs. Floor-Standing

The physical dimensions determine where the autoclave can be installed in your facility.

- Benchtop Autoclaves: These are self-contained units designed to sit on a standard lab bench. They are ideal for labs with limited space or lower throughput needs.

- Floor-Standing Autoclaves: These larger units require dedicated floor space. They often need direct connections to building utilities for water, drainage, and high-amperage electricity.

Orientation: Vertical vs. Horizontal

The loading orientation impacts usability and what types of items can be sterilized efficiently.

- Vertical Autoclaves: These are top-loading units where items are placed down into the chamber. As the references note, they are often smaller and are particularly well-suited for sterilizing tall items like flasks, fermenters, and large media bottles.

- Horizontal Autoclaves: These are front-loading units, similar to a high-powered oven. They are generally available in larger sizes and are better for processing items on trays or in baskets, such as racked glassware, surgical instruments, or biohazard waste bags.

Understanding the Trade-offs

Selecting a size involves balancing capacity against cost, space, and efficiency. An incorrect choice can lead to daily frustration and operational waste.

The Problem with "Too Small"

A small autoclave in a busy lab becomes a major workflow bottleneck. Teams may have to run multiple cycles per day, wasting time and delaying research. It also limits the ability to sterilize larger pieces of equipment, forcing inefficient workarounds.

The Problem with "Too Big"

A large autoclave might seem like a good investment for future growth, but it comes with significant downsides.

- Inefficiency: Running a large chamber for a small load wastes a tremendous amount of water, steam, and electricity.

- Higher Costs: Larger units have a higher purchase price and more demanding installation requirements, which can involve facility modifications.

- Slower Cycles: A larger chamber takes longer to heat up and cool down, which can be detrimental if you need a quick turnaround for a single urgent item.

How to Choose the Right Autoclave Size

Focus on your lab's primary function to determine the best fit. Your choice should be driven by data on your current and projected sterilization needs.

- If your primary focus is a small research lab with varied loads: A medium-sized benchtop model (40-80 L) offers the best blend of flexibility and a manageable footprint.

- If your primary focus is high-throughput media preparation: A large, floor-standing horizontal autoclave (150 L+) with features like active cooling is necessary to keep pace with demand.

- If your primary focus is sterilizing tall equipment like fermenters or large flasks: A top-loading vertical autoclave is often the most space-efficient and practical choice.

- If your primary focus is processing biohazardous waste: Select a size based on your daily waste volume, and prioritize a horizontal unit with features for containing odors and ensuring complete load drying.

Ultimately, the right autoclave is one that seamlessly integrates into your daily operations without causing delays or wasting resources.

Summary Table:

| Autoclave Type | Typical Chamber Volume | Common Use Cases |

|---|---|---|

| Benchtop (Small) | 20-80 Liters | Small research labs, dental offices, specialized tasks |

| Medium (Floor-standing) | 80-200 Liters | Academic, clinical, quality control labs |

| Large (Floor-standing) | 200-1000+ Liters | High-throughput environments, biopharmaceutical production |

Ready to find the perfect autoclave for your lab's needs?

Choosing the right size is critical for efficiency and cost-effectiveness. KINTEK specializes in providing high-quality laboratory autoclaves tailored to your specific workflow, space, and throughput requirements. Our experts can help you avoid the pitfalls of an incorrectly sized unit—whether it's workflow bottlenecks from a unit that's too small or wasted resources from one that's too large.

Contact us today to discuss your lab's autoclave needs and get a personalized recommendation. Let KINTEK be your partner in optimizing your sterilization processes.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What is the primary role of a high-pressure autoclave in the solvothermal synthesis of ZIF-8? Optimize Your MOF Quality

- What is the main purpose of the autoclave? Achieve Complete Sterilization with High-Pressure Steam

- What to look for when buying an autoclave? A Guide to Selecting the Right Sterilization Technology

- What should not be autoclaved? A Guide to Avoiding Damage and Hazard

- Why is a Nickel-based alloy typically selected for the high-pressure autoclave? Ensure Safety & Precision in S-CO2 Testing

- How do high-pressure autoclave systems simulate nuclear reactor environments? Precision sCO2 Corrosion Studies

- How long does it take an autoclave to sterilize goods? It's More Than Just 15 Minutes

- How do you sterilize lab equipment without an autoclave? Discover Reliable Alternatives for Your Lab