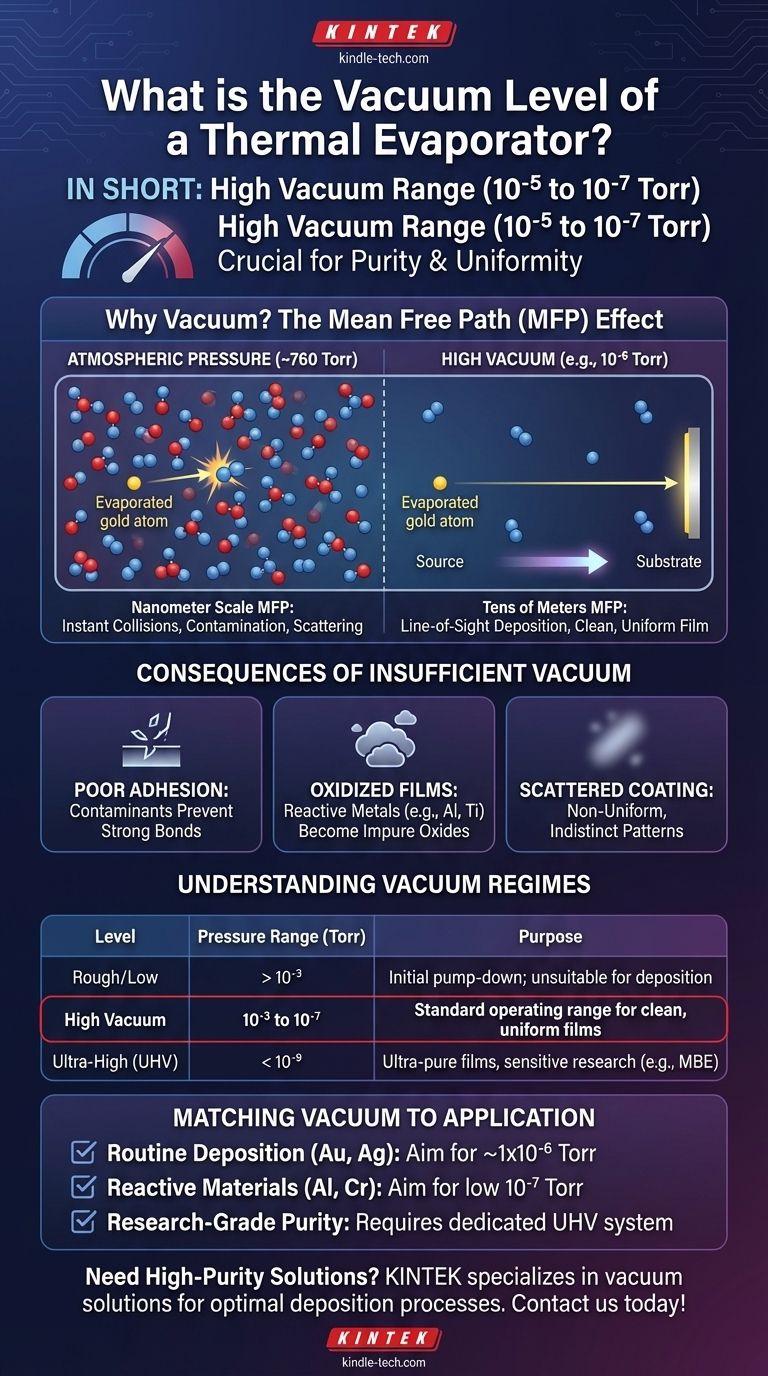

In short, a typical thermal evaporator operates in the high vacuum range, with a base pressure between 10⁻⁵ and 10⁻⁷ Torr (approximately 10⁻⁵ to 10⁻⁷ mbar). The exact pressure required depends heavily on the material being deposited and the desired purity of the final thin film.

The core purpose of the vacuum is not merely to remove air, but to dramatically increase the Mean Free Path of evaporated atoms. This ensures they travel in a straight, uninterrupted line from the source to your substrate, which is the fundamental requirement for creating a clean, uniform, and pure thin film.

Why a Vacuum is Non-Negotiable for Deposition

Achieving a high vacuum is the most critical step in the thermal evaporation process. Without it, the deposition is guaranteed to fail due to two primary physical principles.

The Problem of Contamination

At atmospheric pressure, a vacuum chamber is filled with countless molecules, primarily nitrogen, oxygen, and water vapor. Attempting to deposit a material in these conditions would result in it immediately reacting with or being buried by these contaminants.

A high vacuum removes the vast majority of these residual gas molecules. This ensures that the film you deposit is composed almost entirely of your source material, not an impure mixture of oxides and nitrides.

The Importance of Mean Free Path (MFP)

Mean Free Path (MFP) is the average distance a particle travels before colliding with another particle. This concept is central to understanding why vacuum level matters.

At atmospheric pressure, the MFP is incredibly short—on the scale of nanometers. An evaporated atom would only travel a tiny distance before colliding with an air molecule, scattering it in a random direction.

In a high vacuum (e.g., 10⁻⁶ Torr), the MFP increases to tens of meters. Since the chamber is much smaller than this, an evaporated atom is statistically guaranteed to travel in a straight line from the source to the substrate without any collisions.

Ensuring Line-of-Sight Deposition

This long Mean Free Path creates a "line-of-sight" deposition. The evaporated material travels directly and uniformly from the source, coating only the surfaces it can "see."

This is essential for creating well-defined films and for using techniques like shadow masking, where a physical mask is used to pattern the film. If atoms were scattered by collisions, the pattern would become blurry and indistinct.

Understanding Vacuum Regimes and Their Impact

Not all vacuums are created equal. The pressure level determines the quality of the deposition environment and requires different types of pumping hardware.

Rough/Low Vacuum (> 10⁻³ Torr)

This is the first stage of pumping, achieved with mechanical pumps like rotary vane or scroll pumps. This stage simply removes the bulk of the air from the chamber. It is impossible to perform a quality deposition in this pressure range.

High Vacuum (10⁻³ to 10⁻⁷ Torr)

This is the standard operating range for most thermal evaporators. After reaching a rough vacuum, a secondary pump, such as a turbomolecular pump or diffusion pump, takes over to achieve this much lower pressure. This is the range where the Mean Free Path becomes long enough for high-quality deposition.

Ultra-High Vacuum (UHV) (< 10⁻⁹ Torr)

UHV is required for the most sensitive applications where even minuscule levels of contamination are unacceptable, such as in molecular beam epitaxy (MBE) or research on pristine surfaces. Achieving UHV requires specialized pumps, all-metal seals, and a process called "bake-out" to drive trapped water molecules out of the chamber walls.

The Consequences of an Insufficient Vacuum

Cutting corners on your vacuum level will directly and negatively impact the quality of your results.

Oxidized and Impure Films

If the base pressure is too high, reactive materials like aluminum, chromium, or titanium will readily react with the residual oxygen and water vapor. Instead of a pure metallic film, you will deposit a cloudy, resistive metal oxide.

Poor Film Adhesion

Contaminants from a poor vacuum can settle on the substrate surface before and during deposition. This microscopic layer of dirt prevents the deposited film from forming a strong bond, leading to it peeling or flaking off easily.

Non-Uniform and Scattered Coatings

If the pressure is high enough to shorten the Mean Free Path, the evaporated atoms will be scattered. This prevents a sharp, uniform coating and makes precise patterning with a shadow mask impossible.

Matching the Vacuum Level to Your Application

The ideal vacuum level is a function of your specific goal. Higher vacuum is always better for film purity, but it comes at the cost of longer pump-down times and more complex equipment.

- If your primary focus is routine deposition of non-reactive metals (e.g., gold, silver): A base pressure of 1x10⁻⁶ Torr is a robust and effective target for most applications.

- If your primary focus is depositing reactive materials (e.g., aluminum, chromium, titanium): Aim for the lowest base pressure your system can achieve, ideally in the low 10⁻⁷ Torr range, to minimize oxidation.

- If your primary focus is creating research-grade, atomically pure films: You need to move beyond standard thermal evaporation into a dedicated UHV system designed for ultimate purity.

Ultimately, controlling the vacuum environment is the foundational step that dictates the quality, purity, and performance of your deposited thin film.

Summary Table:

| Vacuum Level | Pressure Range (Torr) | Purpose in Thermal Evaporation |

|---|---|---|

| Rough/Low Vacuum | > 10⁻³ | Initial pump-down; not suitable for deposition |

| High Vacuum | 10⁻³ to 10⁻⁷ | Standard operating range for clean, uniform films |

| Ultra-High Vacuum (UHV) | < 10⁻⁹ | For ultra-pure films (e.g., MBE, sensitive research) |

Need a reliable thermal evaporator for high-purity thin films? KINTEK specializes in lab equipment and consumables, providing vacuum solutions that ensure optimal mean free path and minimal contamination for your deposition processes. Let our experts help you achieve the precise vacuum control your research demands. Contact us today to discuss your laboratory needs!

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is the process of gold sputtering? A Guide to High-Precision Thin Film Deposition

- When and why does arcing occur? Understand the Physics to Prevent Costly Damage

- What do you need to braze stainless steel? Master the 3 Keys to a Perfect Joint

- What are the safety precautions for brazing? Protect Yourself from Heat, Fumes, and Fire

- What does CIP stand for Crip? Understanding the Meaning of Crip In Peace

- What is the most efficient means of separating solids from surrounding liquid through gravity? Optimize with Coagulation & Clarifiers

- Is lab-grown diamond legal? Yes, and here's why they're a legitimate choice

- What is sputter ceramic film? A High-Tech Solution for Superior Heat Rejection & Clarity