The most critical precautions in a chemistry lab revolve around a foundational respect for the materials and processes involved. At a minimum, this includes wearing appropriate Personal Protective Equipment (PPE) at all times, understanding the specific hazards of every chemical you use before you handle it, and knowing the precise location and operation of all emergency safety equipment. Never work alone, and always maintain a clean and organized workspace to prevent accidents.

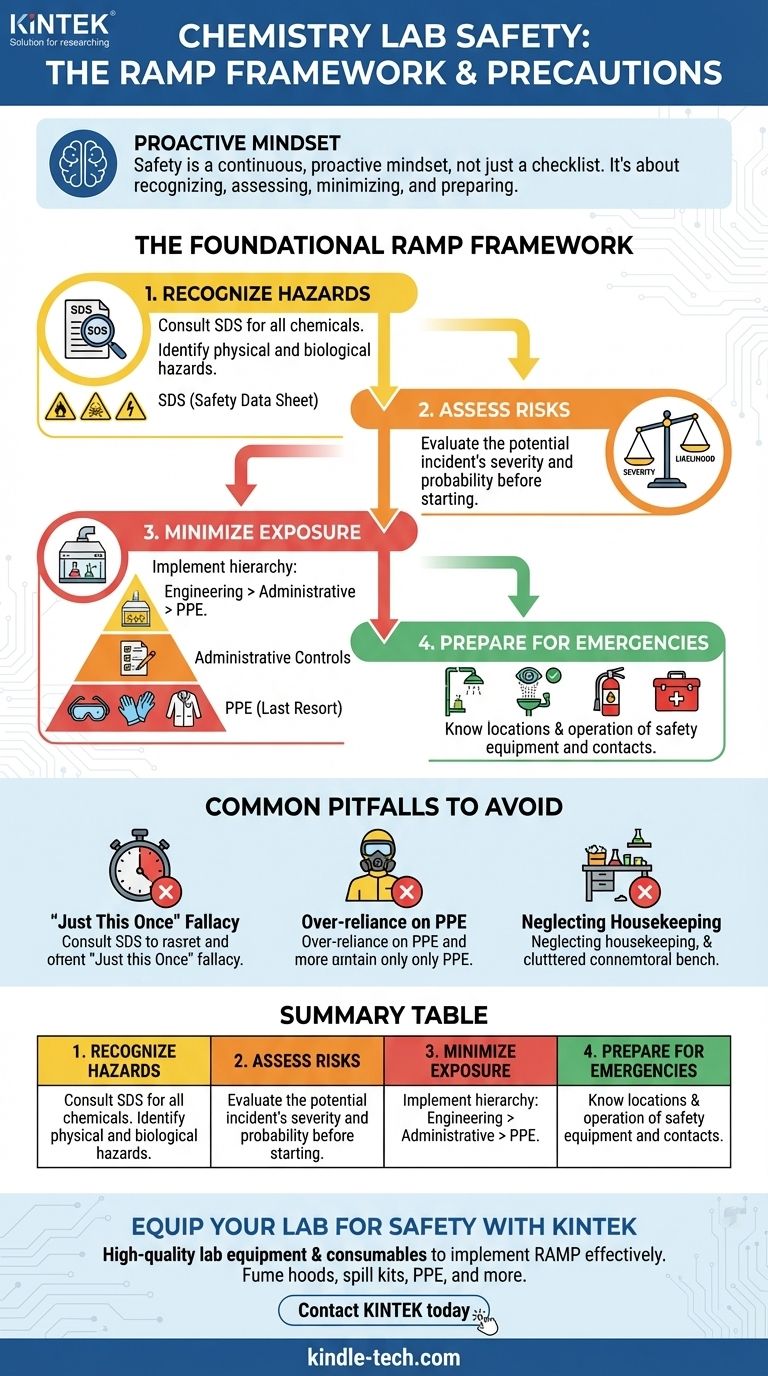

True laboratory safety is not a checklist of rules to be memorized, but a continuous, proactive mindset. It is built on a framework of recognizing hazards, assessing risks, minimizing exposure, and preparing for emergencies before an experiment even begins.

The Foundational Framework: RAMP

A robust safety culture is built on the RAMP principle, a simple yet powerful framework for approaching every task in the laboratory.

Recognize the Hazards

Before any work begins, you must identify the potential sources of harm. Hazards are not always obvious.

Every chemical has an associated Safety Data Sheet (SDS), formerly known as an MSDS. This document is your primary source of information on flammability, toxicity, reactivity, and required safety measures.

Beyond chemicals, consider physical hazards like high-pressure systems, extreme temperatures, and electrical equipment. Biological hazards, if applicable, also require their own specific protocols.

Assess the Risks

Recognizing a hazard is the first step; assessing its risk is next. Risk is the combination of the severity of a potential incident and the likelihood of it occurring.

Ask yourself: What is the worst-case scenario? How could this experiment fail? A small quantity of a mild irritant poses a very different risk than a large volume of a highly corrosive or explosive substance.

This assessment dictates the level of control measures you will need to implement for the procedure.

Minimize the Hazards

This is the active part of safety—implementing controls to reduce risk. This happens in a clear hierarchy.

The most effective method is using engineering controls, which are physical installations that remove the hazard. The single most important example is the chemical fume hood, which ventilates toxic or volatile vapors away from the user.

Next comes administrative controls, which are the procedures and protocols you follow. This includes proper labeling of all containers, never working alone, and developing a Standard Operating Procedure (SOP) for your experiment.

The last line of defense is Personal Protective Equipment (PPE). This includes splash-proof chemical goggles, a flame-resistant lab coat, appropriate chemical-resistant gloves, and closed-toe shoes. PPE does not prevent the incident, but it can protect you from injury if one occurs.

Prepare for Emergencies

Even with the best planning, accidents can happen. Preparation is non-negotiable.

You must know the exact location and proper use of the safety shower, eyewash station, fire extinguisher, and spill kit. Seconds count in an emergency, and there is no time to look for instructions.

Ensure emergency contact numbers are clearly posted and that you understand the lab's specific procedure for reporting incidents, no matter how minor they may seem.

Common Pitfalls and Misconceptions

Adherence to safety protocols can be undermined by complacency and a misunderstanding of where the real dangers lie. Avoiding these common traps is as important as following the rules themselves.

The "Just This Once" Fallacy

The vast majority of lab accidents are not caused by exotic, high-risk procedures. They are caused by a minor deviation from a routine task—skipping goggles for a "quick" transfer or failing to use the fume hood for a "small" amount of a chemical.

This normalization of deviance is the single greatest threat to a safe lab culture. There is no such thing as a task so quick that it warrants skipping basic safety measures.

Over-reliance on PPE

Many see PPE as the primary tool for safety. This is incorrect. PPE is the last line of defense, intended to protect you when all other controls have failed.

Relying on gloves to protect you from a splash is far less effective than implementing a procedure that prevents the splash from happening in the first place. Always prioritize engineering and administrative controls over PPE.

Neglecting Good Housekeeping

A cluttered bench, unlabeled containers, and blocked emergency exits create unnecessary and entirely avoidable hazards. A clean and organized lab is a direct reflection of a professional and safety-conscious mindset.

Good housekeeping is not about tidiness for its own sake; it is a critical administrative control that reduces the likelihood of spills, cross-contamination, and trips or falls.

Applying This to Your Role

Your approach to safety depends on your responsibilities within the laboratory environment.

- If you are a lab manager or principal investigator: Your primary focus is on establishing robust engineering controls and fostering a culture where safety protocols are consistently and universally followed.

- If you are a researcher or student: Your primary focus is on personal responsibility—thoroughly understanding the RAMP principles for every task you perform and never proceeding if you feel unprepared or unsure.

- If you are designing or setting up a new lab: Your primary focus must be on building safety into the physical environment from the outset, with correct ventilation, logical workflow, and easily accessible emergency equipment.

Ultimately, excellent science and excellent safety are inseparable.

Summary Table:

| Precaution Category | Key Actions |

|---|---|

| Recognize Hazards | Consult Safety Data Sheets (SDS) for all chemicals. Identify physical and biological hazards. |

| Assess Risks | Evaluate the severity and likelihood of potential incidents before starting work. |

| Minimize Hazards | Use engineering controls (e.g., fume hoods), administrative controls, and wear appropriate PPE. |

| Prepare for Emergencies | Know the location and operation of safety showers, eyewash stations, fire extinguishers, and spill kits. |

| Avoid Common Pitfalls | Never skip safety measures for "quick" tasks. Prioritize controls over just PPE. Maintain a clean workspace. |

Equip Your Lab for Safety and Success with KINTEK

Creating a safe laboratory environment is the foundation of reliable research and discovery. At KINTEK, we understand that your work depends on a secure and well-equipped space. We specialize in providing the high-quality lab equipment and consumables you need to implement the RAMP framework effectively.

Whether you are a lab manager establishing a new facility or a researcher requiring reliable safety gear, KINTEK is your trusted partner. From chemical fume hoods and spill kits to personal protective equipment (PPE), we supply the tools that help you minimize hazards and protect your team.

Ready to build a stronger safety culture in your lab? Let our experts help you select the right equipment for your specific needs.

Contact KINTEK today to discuss your laboratory safety requirements!

Visual Guide

Related Products

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Evaporation Crucible for Organic Matter

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- How do you heat treat aluminium castings? A 3-Step Guide to Boost Strength & Durability

- How does a high-speed disperser contribute to graphene oxide synthesis? Optimize Exfoliation & Chemical Efficiency

- Why sputter coating is used for specimen preparation? Prevent Charging for Clear SEM Imaging

- What is sintering with an example? A Guide to Fusing Powders into Solid Parts

- How is a sputtering target made? A Guide to Manufacturing High-Performance Thin Film Sources

- What are the defects that occur during heat treatment of steel? Prevent Cracking, Warping & Soft Spots

- At what temperature does pyrolysis occur? A Guide to Controlling Your Product Output

- What is the HIP process in casting? Achieve Dense, High-Performance Metal Components