At its core, injection molding is a manufacturing process for producing parts by injecting molten material into a mold. This method is responsible for an astonishingly vast range of the plastic items we use daily, from simple bottle caps and containers to complex electronic housings, toys, automotive components, and even outdoor furniture.

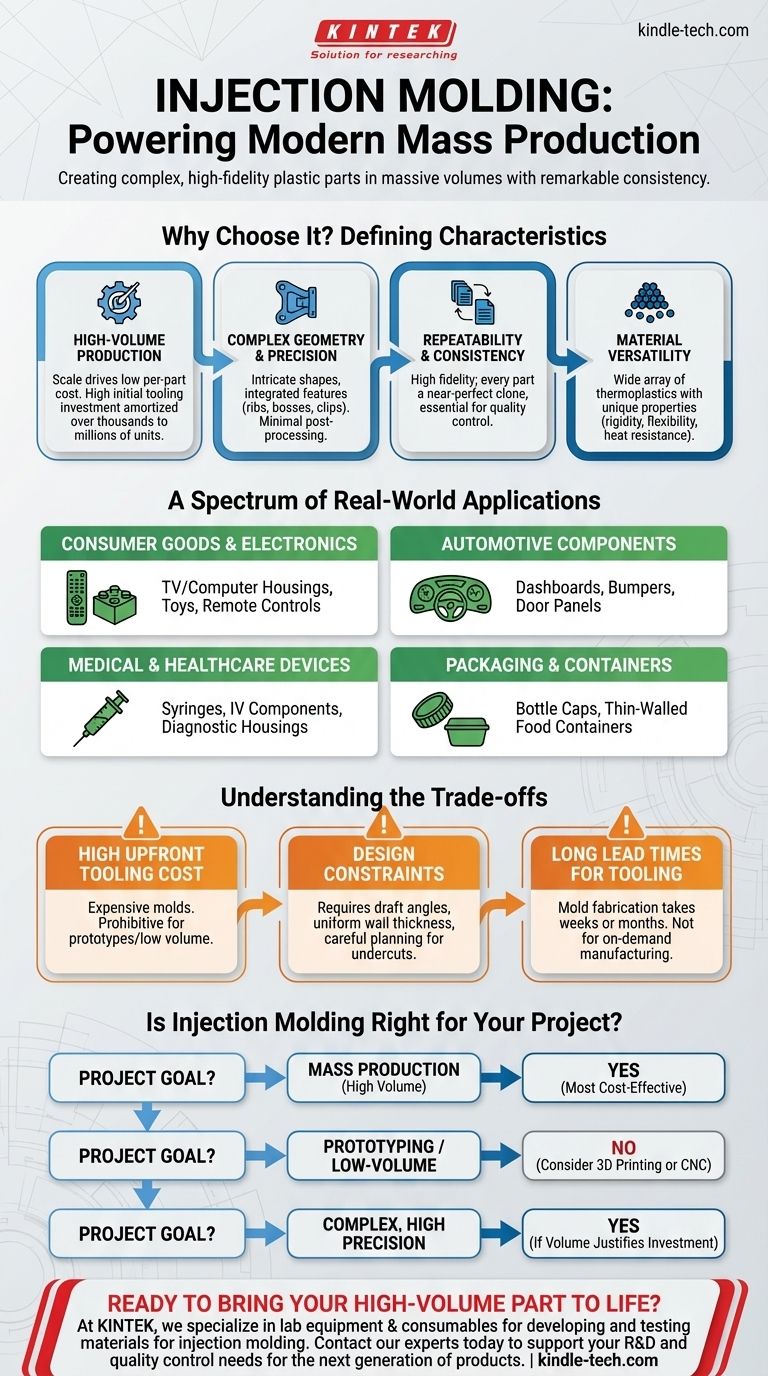

The true question isn't what can be made with injection molding, but why it's chosen. The process excels at producing complex, highly detailed plastic parts in massive volumes with remarkable consistency, making it the backbone of modern mass production.

The Defining Characteristics of an Injection Molded Part

To understand if a product is a good candidate for injection molding, you must look beyond its function and analyze its required physical and economic characteristics. The process is defined by a few key principles.

High-Volume Production

The primary driver for using injection molding is scale. The steel mold, or "tool," is expensive and time-consuming to create, often costing thousands or even tens of thousands of dollars.

This high upfront cost is only justifiable when amortized over a large production run, typically from thousands to millions of units. This is when the per-part cost becomes exceptionally low.

Complex Geometry and Precision

Injection molding is unparalleled in its ability to create intricate and complex shapes. Features like strengthening ribs, screw bosses for assembly, and snap-fit clips can be integrated directly into the part design.

This allows for the creation of sophisticated components that require minimal post-processing or assembly, reducing overall manufacturing complexity and cost.

Repeatability and Consistency

Once the mold is perfected, the process produces parts with extremely high fidelity and consistency from one unit to the next.

This repeatability is critical for products that require tight tolerances for assembly and for maintaining quality control across a massive production run. Every part is a near-perfect clone of the one before it.

Material Versatility

A wide array of thermoplastic polymers can be used in injection molding, each with unique properties.

Manufacturers can select materials to achieve specific goals, such as rigidity, flexibility, impact resistance, UV stability, or heat resistance, tailoring the part's performance to its intended environment.

A Spectrum of Real-World Applications

The principles of volume, complexity, and consistency make injection molding ubiquitous across numerous industries.

Consumer Goods and Electronics

This is perhaps the most visible application. Items like television components, remote controls, computer housings, and the iconic bricks in toy construction sets are all classic examples.

Automotive Components

The automotive industry relies heavily on injection molding for interior parts like dashboards, door panels, and buttons. It's also used for exterior components like bumpers and grilles where strength-to-weight ratio is important.

Medical and Healthcare Devices

The process is ideal for producing sterile, single-use medical products like syringes, IV components, and housings for diagnostic equipment. Its high repeatability is essential for life-critical applications.

Packaging and Containers

Nearly every plastic bottle cap and thin-walled food container is injection molded. The process is optimized for producing these high-volume, low-cost items with incredible speed.

Understanding the Trade-offs

Despite its advantages, injection molding is not the right choice for every project. Understanding its limitations is crucial for making an informed decision.

The High Upfront Cost of Tooling

The single greatest barrier to entry is the cost of creating the mold. For prototypes, one-off parts, or low-volume production runs, this cost is prohibitive.

Design Constraints

Parts must be designed for injection molding. This includes requirements like adding draft angles (slight tapers) so the part can be ejected from the mold, maintaining uniform wall thickness to prevent defects, and carefully planning for features like undercuts that can dramatically increase mold complexity and cost.

Long Lead Times for Tooling

Fabricating a high-quality production mold is a precise process that can take weeks or even months. This is not a method for rapid or on-demand manufacturing.

Is Injection Molding Right for Your Project?

Choosing the right manufacturing process depends entirely on your specific goals for volume, cost, and speed.

- If your primary focus is mass production (tens of thousands to millions of units): Injection molding is almost certainly the most cost-effective method for producing your plastic part.

- If your primary focus is prototyping or low-volume production (1 to 1000 units): The high tooling cost makes injection molding unsuitable; consider alternatives like 3D printing or CNC machining instead.

- If your primary focus is creating a complex plastic part with high precision: Injection molding is the gold standard, provided your expected volume justifies the initial investment in tooling.

Ultimately, injection molding is the engine of mass production, enabling the creation of consistent, complex, and affordable plastic goods that shape our world.

Summary Table:

| Product Category | Key Examples | Why Injection Molding is Ideal |

|---|---|---|

| Consumer Goods & Electronics | TV/Computer Housings, Toys, Remote Controls | High volume, complex geometry, precision |

| Automotive Components | Dashboards, Bumpers, Door Panels | High strength-to-weight ratio, consistency |

| Medical Devices | Syringes, IV Components, Diagnostic Housings | Sterility, high repeatability, precision |

| Packaging | Bottle Caps, Thin-Walled Containers | Extremely high volume, low per-part cost |

Ready to bring your high-volume plastic part to life?

At KINTEK, we specialize in providing the lab equipment and consumables necessary for developing and testing materials for injection molding. Whether you're in R&D or quality control, our solutions help ensure your materials meet the rigorous demands of mass production.

Contact our experts today to discuss how we can support your laboratory's role in creating the next generation of injection molded products.

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- Anti-Cracking Press Mold for Lab Use

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What are the three 3 differences between compression molding and injection molding? Choose the Right Process for Your Project

- What can you make with an injection moulding machine? Mass-Produce High-Quality Plastic Parts Efficiently

- What is a positive of injection moulding? Achieve High-Volume Production with Unmatched Efficiency

- What is short capacity of injection Moulding machine? Optimize Your Shot Size for Flawless Parts

- What are the parameters to be considered for selecting the thin wall molding machine? Key Specs for High-Speed Production