An autoclave does not have a specific opening temperature; rather, it unlocks only after the sterilization cycle is fully complete and both the internal chamber pressure and temperature have returned to safe, ambient levels. Opening an autoclave while it is hot and pressurized is extremely dangerous and is prevented by built-in safety mechanisms.

The critical factor for opening an autoclave is not temperature, but pressure. The door's safety interlock is designed to remain locked until the internal chamber pressure has completely equalized with the outside atmosphere, ensuring it is safe to open.

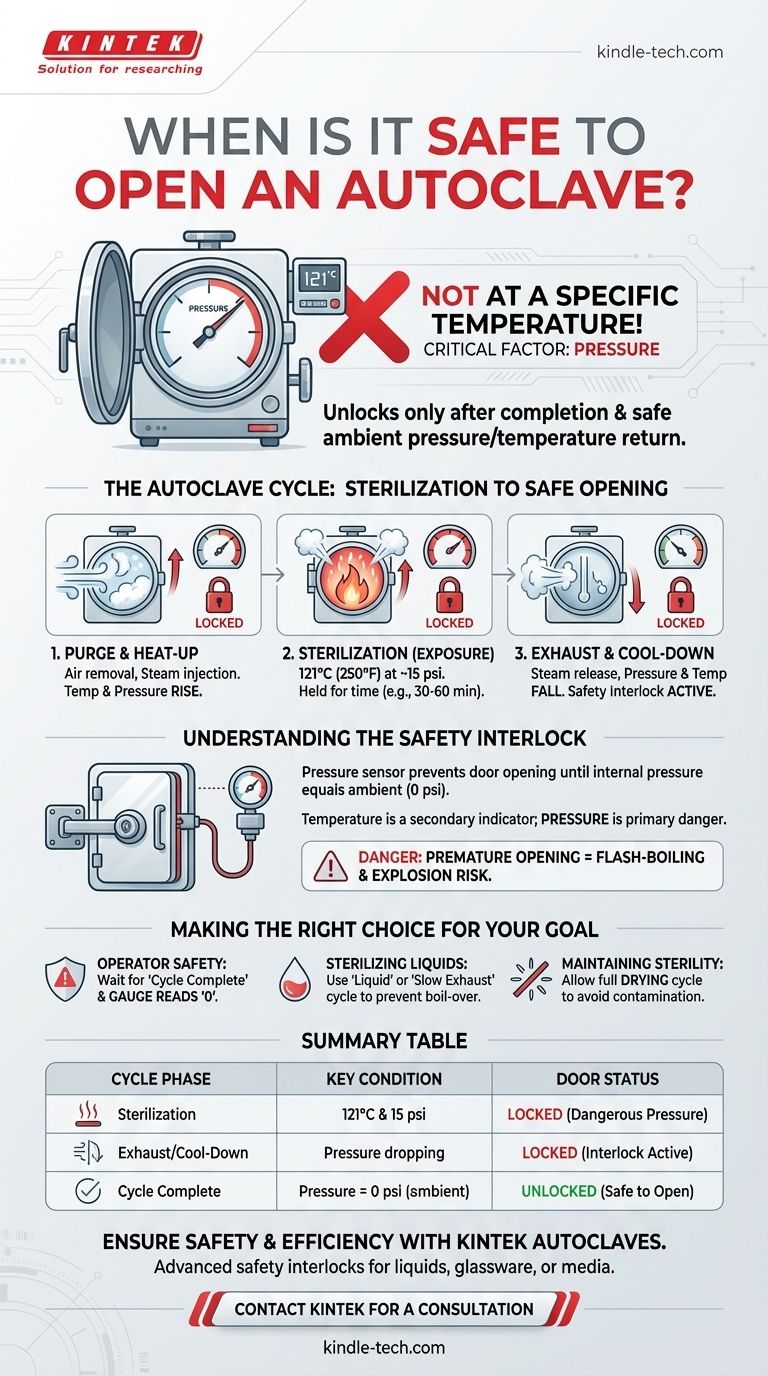

The Autoclave Cycle: From Sterilization to Safe Opening

To understand when an autoclave can be opened, you must first understand its operational cycle. The high temperature mentioned in manuals (121°C or 250°F) is the sterilization temperature, not the opening temperature.

Phase 1: Purge and Heat-Up

Before sterilization can begin, all air must be removed from the chamber. This is because trapped air acts as an insulator, preventing the steam from reaching all surfaces and compromising the entire process.

Pressurized steam is pulsed into the chamber to displace the cooler, denser air, which is vented out. During this phase, the chamber temperature and pressure begin to rise toward their target.

Phase 2: Sterilization (Exposure)

Once all air is purged, the autoclave seals and injects steam until the chamber reaches the standard sterilization conditions.

For most general laboratory applications, this is a temperature of 121°C (250°F) under approximately 15 psi (pounds per square inch) of pressure. The load is held at these conditions for a set duration, typically 30-60 minutes, to ensure all microorganisms are killed.

Phase 3: Exhaust and Cool-Down

This is the most critical phase related to your question. After the sterilization time is complete, the steam must be released, and the chamber must cool down.

The exhaust valve opens to slowly vent the pressurized steam, causing the pressure inside the chamber to drop. As pressure decreases, the temperature of the remaining steam and the sterilized contents also falls.

Understanding the Key Safety Mechanism: The Interlock

Modern autoclaves are equipped with a crucial safety feature that makes it physically impossible to open the door under dangerous conditions.

The Role of Pressure

The autoclave door has a locking mechanism directly linked to a pressure sensor inside the chamber. This interlock will not release the door until the sensor detects that the internal pressure has returned to zero (i.e., it has equalized with the ambient room pressure).

Why Temperature is a Secondary Indicator

While the chamber must cool down, pressure is the primary danger. Even at a temperature below boiling (e.g., 90°C), any residual pressure can cause the door to fly open with explosive force and release scalding steam. Therefore, safety systems are designed to prioritize pressure normalization above all else.

The Danger of Premature Opening

Attempting to bypass safety interlocks or force a door open can lead to catastrophic failure. The sudden depressurization would cause any water in the chamber to flash-boil instantly, creating an explosion of steam, boiling water, and potentially launching the contents across the room.

Making the Right Choice for Your Goal

Always follow the manufacturer's specific instructions for your model, but the principles remain the same.

- If your primary focus is operator safety: Always wait for the autoclave to signal the cycle is complete and verify that the chamber pressure gauge reads "0" before attempting to open the door.

- If your primary focus is sterilizing liquids: Use the specific "liquid" or "slow exhaust" cycle, which cools down much more slowly to prevent the liquids from boiling over and creating a mess or safety hazard.

- If your primary focus is maintaining sterility of the load: Allow the drying cycle (if available) to finish completely, as opening the door while contents are still wet can allow airborne microbes to contaminate the items.

Ultimately, the safe operation of an autoclave depends on allowing its automated process to run to completion without interference.

Summary Table:

| Autoclave Cycle Phase | Key Condition | Door Status |

|---|---|---|

| Sterilization (Exposure) | 121°C (250°F) & 15 psi | Locked - Dangerous pressure |

| Exhaust & Cool-Down | Pressure dropping, temperature falling | Locked - Safety interlock active |

| Cycle Complete / Safe to Open | Chamber pressure = 0 psi (ambient) | Unlocked - Safe to open |

Ensure your lab's safety and efficiency with the right autoclave.

At KINTEK, we specialize in reliable laboratory equipment, including autoclaves designed with advanced safety interlocks to protect your team. Our experts can help you select the perfect sterilizer for your specific needs, whether you're processing liquids, glassware, or media.

Let KINTEK provide the reliable equipment your lab depends on.

Contact us today for a consultation to find the ideal autoclave solution for your laboratory.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What is the role of the Bowie-Dick-Test in waste decontamination? Focus on Lab Efficiency & Compliance

- What is the importance of using a laboratory autoclave in ZSM-5 synthesis? Achieve Perfect Zeolite Crystallization

- What is the pressure of autoclave at 121 C? The Key to Effective Steam Sterilization

- What is the function of a laboratory autoclave in dilute acid pretreatment? Unlock Biomass Energy Efficiently

- What are examples of autoclave in microbiology? Essential Sterilization for Lab Safety & Accuracy

- How long does autoclaving take? Mastering Sterilization Times for Your Lab

- What are the applications of autoclave? Essential Sterilization for Medical, Lab, and Industrial Needs

- Why is autoclaving rather than boiling water used for sterilization? Achieve True Sterility for Your Lab