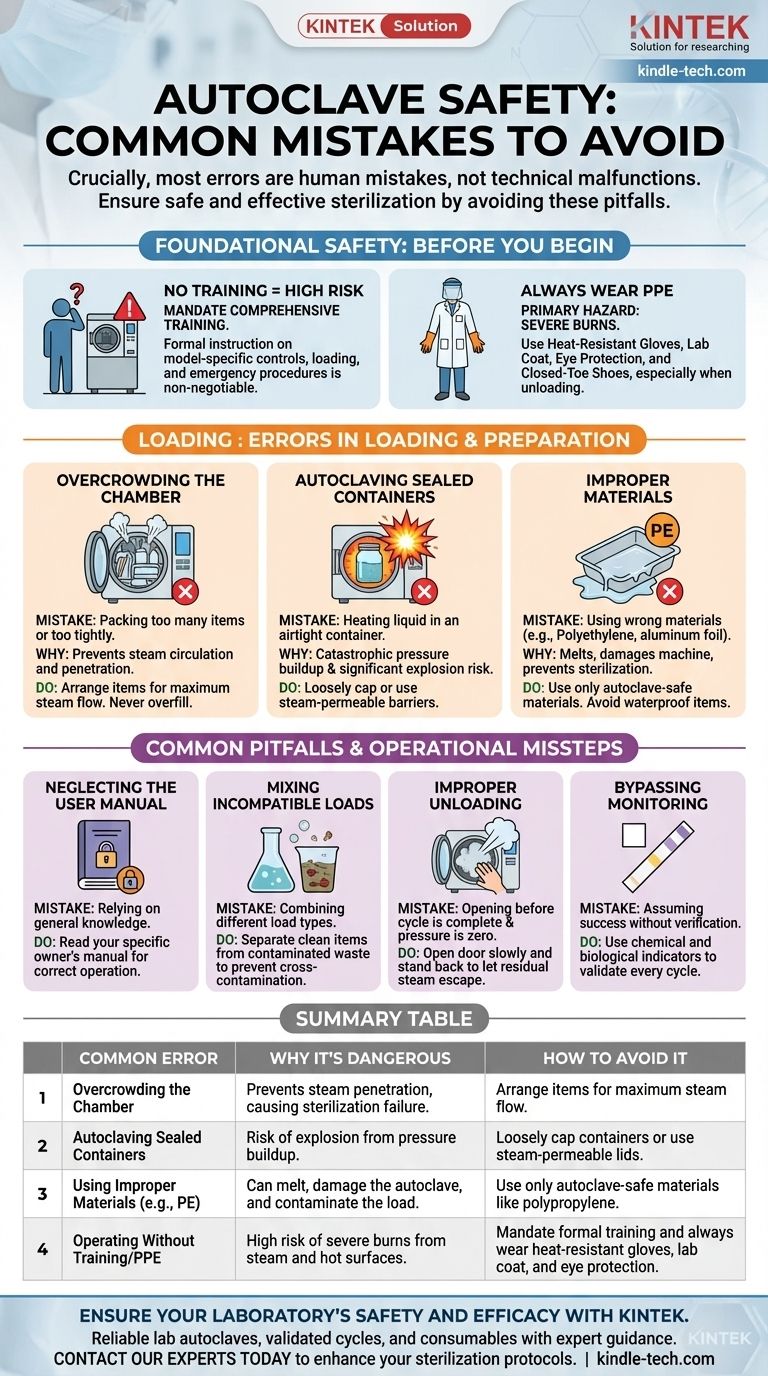

Crucially, the most common and dangerous errors when using an autoclave are not technical malfunctions but simple human mistakes. To use one safely, you must avoid overcrowding the chamber, autoclaving liquids in sealed containers, using improper materials like polyethylene or aluminum foil, and operating the machine without formal training and proper personal protective equipment.

The core principle of safe autoclaving is ensuring unimpeded steam penetration and respecting the immense pressure and heat involved. Most errors stem from either blocking the steam's path, creating an explosion risk, or mishandling the post-cycle hazards of a hot, pressurized chamber.

Foundational Safety: Before You Even Begin

Proper operation starts long before you press the "start" button. These preliminary steps are non-negotiable for ensuring both user safety and effective sterilization.

Mandate Comprehensive Training

No one should operate an autoclave without being formally trained. An autoclave is a high-pressure vessel, and improper use can lead to serious injury or equipment damage.

Training must cover the specific model in use, including its controls, proper loading and unloading protocols, and emergency procedures.

Always Use Personal Protective Equipment (PPE)

The primary hazards are severe burns from superheated steam and hot materials. Always wear the required PPE, especially when unloading.

This includes heat-resistant gloves, a lab coat, full eye protection, and closed-toe shoes.

Critical Errors in Loading and Preparation

How you prepare and load the autoclave directly determines whether the sterilization cycle will succeed or fail. Most sterilization failures can be traced back to these steps.

Avoid Overcrowding the Chamber

This is perhaps the most frequent mistake. Placing too many items in the chamber or packing them too tightly prevents steam from circulating and penetrating the entire load.

Items should be arranged to allow for maximum steam flow around them. Never overfill bags or containers.

Never Autoclave Sealed Containers

Heating a liquid in a sealed, airtight container will cause a catastrophic pressure buildup, creating a significant risk of explosion.

All containers with liquids must be loosely capped or covered with a steam-permeable barrier to allow pressure to equalize safely.

Choose Materials Wisely

Not all materials are safe for the autoclave. Using the wrong ones can ruin your items, contaminate your load, or damage the machine itself.

- Do not use polyethylene (PE) trays or containers, as they will melt at autoclave temperatures and can cause severe damage.

- Avoid waterproof or water-resistant materials like oils and greases, as steam cannot penetrate them to achieve sterilization.

- Do not wrap items tightly in aluminum foil, as it acts as a steam barrier and prevents sterilization of the contents.

Ensure Proper Water Levels

The autoclave generates steam from a reservoir of water. Operating it with too little water can damage the heating elements and cause the cycle to fail.

Always check that the water is at the level indicated by the manufacturer, and use deionized or distilled water to prevent mineral buildup.

Common Pitfalls and Operational Missteps

Even with a well-prepared load, mistakes during and after the cycle can compromise safety and effectiveness.

Neglecting the User Manual

Every autoclave model has unique operating procedures, cycle settings, and safety features. Relying on general knowledge is insufficient.

Read and understand the owner's manual for your specific machine. It is the definitive guide for correct and safe operation.

Mixing Incompatible Loads

Good practice dictates separating different types of loads to prevent cross-contamination and ensure the correct cycle is run for each.

Clean items (like glassware and media) should always be autoclaved in separate cycles from contaminated waste.

Improper Unloading

The cycle's end does not mean the danger is over. The chamber and its contents remain extremely hot and under pressure.

Never attempt to open the autoclave door until the cycle is complete and the chamber pressure has returned to zero. Open the door slowly and stand back to allow residual steam to escape.

Bypassing Monitoring Protocols

Assuming a cycle was successful without verification is a critical error. A proper monitoring protocol ensures sterilization was actually achieved.

Use chemical indicators in every load to show it has reached temperature, and perform periodic biological indicator tests to validate the autoclave is functioning correctly.

Making the Right Choice for Your Goal

Your approach to using an autoclave should be guided by your primary objective, whether it's user safety, sterilization efficacy, or equipment care.

- If your primary focus is personnel safety: Prioritize comprehensive training and the consistent use of proper PPE above all else.

- If your primary focus is effective sterilization: Master proper loading techniques to ensure steam penetration and use chemical and biological indicators to validate every cycle.

- If your primary focus is equipment longevity: Use only appropriate materials, maintain correct water levels with purified water, and adhere to the manufacturer's maintenance schedule.

By understanding that an autoclave relies on pressurized steam, not just dry heat, you can anticipate and prevent nearly every common failure.

Summary Table:

| Common Error | Why It's Dangerous | How to Avoid It |

|---|---|---|

| Overcrowding the Chamber | Prevents steam penetration, causing sterilization failure. | Arrange items for maximum steam flow. |

| Autoclaving Sealed Containers | Risk of explosion from pressure buildup. | Loosely cap containers or use steam-permeable lids. |

| Using Improper Materials (e.g., PE) | Can melt, damage the autoclave, and contaminate the load. | Use only autoclave-safe materials like polypropylene. |

| Operating Without Training/PPE | High risk of severe burns from steam and hot surfaces. | Mandate formal training and always wear heat-resistant gloves, lab coat, and eye protection. |

Ensure your laboratory's safety and sterilization efficacy with the right equipment and support. KINTEK specializes in providing reliable lab autoclaves and consumables, backed by expert guidance to help you avoid common pitfalls. Whether you need a new autoclave, validated cycles, or consumables like indicator tape and biological monitors, we are here to support your laboratory's needs. Contact our experts today to discuss how we can enhance your sterilization protocols and protect your team.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What are the tips for using an autoclave? Ensure Effective Sterilization and Safety

- What is the process of autoclaving? A Step-by-Step Guide to Sterilization

- Why is autoclave temperature 121°C? The Science Behind Sterilization's Critical Point

- What is the difference between 121 and 134 autoclave? Choose the Right Sterilization Cycle

- What type of sterilizer is used for sterilizing liquids? Choose the Right Method for Your Lab

- What equipment can be autoclaved? A Guide to Material Compatibility and Sterilization

- What is the difference between gravity and pre vacuum autoclave? Choose the Right Sterilization Method

- What role does a laboratory autoclave play in the separation of lignin? High-Purity Extraction for Biomass Research