Understanding the limits of steam sterilization is critical for maintaining the integrity of your instruments and ensuring effective decontamination. You cannot autoclave materials that are sensitive to heat and moisture, including many plastics, delicate electronics, and high-carbon steel instruments. Additionally, substances that repel water, such as oils and powders, cannot be reliably sterilized with steam because the process depends on direct moisture contact to kill microbes.

The core principle is simple: an autoclave sterilizes with high-pressure, high-temperature steam. Therefore, any material that can be melted, corroded, dulled, or degraded by heat and moisture, or any substance that steam cannot penetrate, is not a suitable candidate for this method.

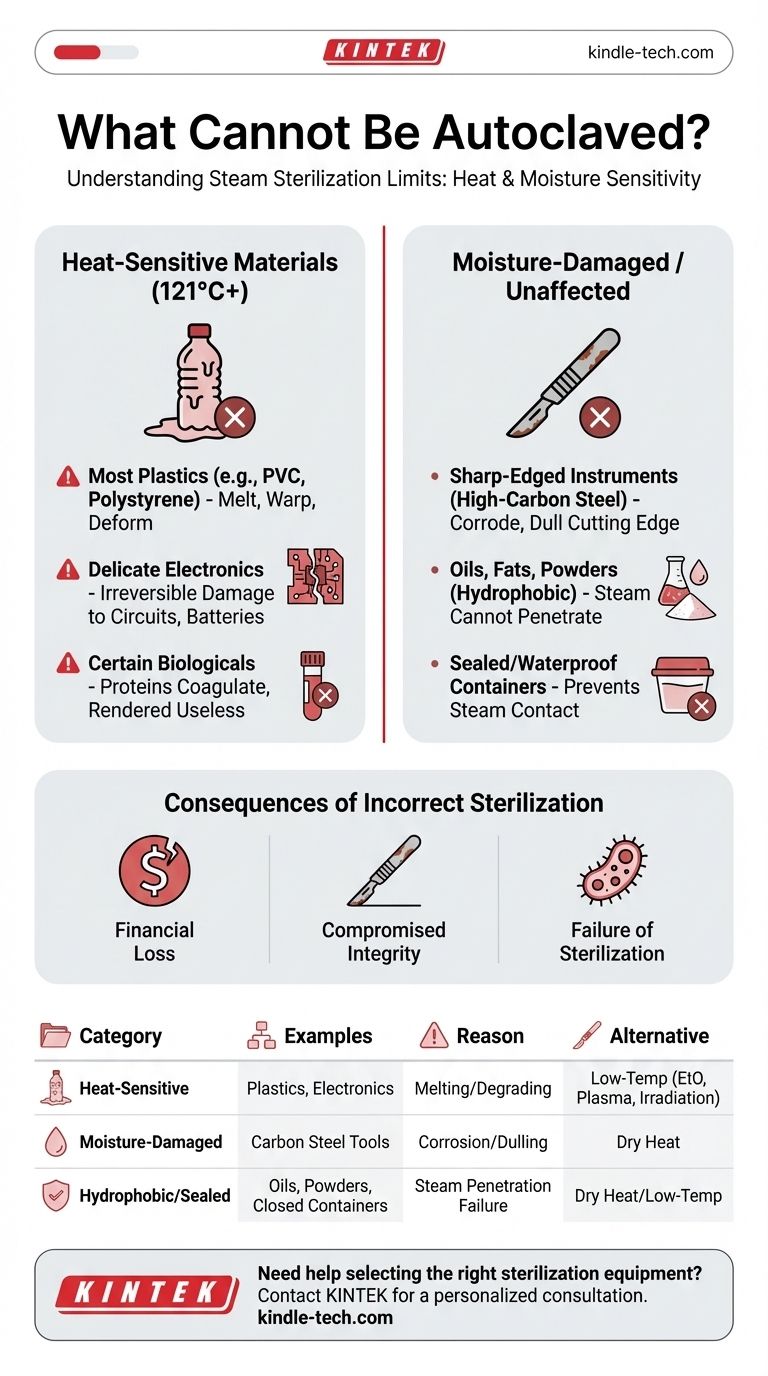

Why Heat and Moisture Preclude Autoclaving

The effectiveness of an autoclave—its ability to use saturated steam to denature microbial proteins—is also its primary limitation. Any material that cannot withstand temperatures of at least 121°C (250°F) and high-pressure moisture will be damaged or destroyed.

Heat-Sensitive Materials

Many common laboratory and medical items will melt, warp, or degrade under autoclave conditions.

- Most Plastics: Standard polymers like polyethylene, PVC, and polystyrene have low melting points and will deform or melt completely. Only specific, heat-resistant plastics like polypropylene (PP) and polytetrafluoroethylene (PTFE) are designed to be autoclavable.

- Delicate Electronics: Any instrument containing batteries, circuits, or electronic sensors will be irreversibly damaged by the extreme heat and penetrating moisture.

- Certain Biologicals: High-protein solutions, serums, and vaccines can be denatured by excessive heat, rendering them useless. The proteins coagulate, much like an egg white does when cooked.

Materials Damaged or Unaffected by Moisture

Steam must be able to directly contact every surface for sterilization to occur. If a material repels water or is degraded by it, the process fails.

- Sharp-Edged Instruments: High-grade carbon steel, often used for premium scalpels and scissors, will dull and corrode in an autoclave. The high-temperature steam accelerates oxidation (rusting), which destroys the fine cutting edge. In contrast, most stainless steel is formulated to resist this.

- Oils, Fats, and Powders: These materials are hydrophobic (water-repelling). Steam cannot penetrate them, leaving microbes insulated and alive within the substance. It creates a dangerous false sense of sterility.

- Sealed or Waterproof Containers: Steam cannot penetrate a sealed container to sterilize the contents inside. Lids must be loosely fitted or vented to allow for steam exchange.

Understanding the Trade-offs

Choosing the wrong sterilization method is not just ineffective; it can be costly and dangerous. Understanding the risks is key to making the right decision.

Risk of Damaging Equipment

The most immediate consequence is financial. Attempting to autoclave an expensive piece of electronic equipment or a non-autoclavable plastic scope will result in its destruction. Always verify an instrument's compatibility before processing.

Compromising Instrument Integrity

For sharp instruments, the trade-off is performance and safety. Autoclaving a carbon steel scalpel blade makes it dull. A dull blade requires more pressure to cut, increasing the risk of tissue damage and injury to the operator.

Failure of Sterilization

The most serious risk is incomplete sterilization. Placing oils or powders in an autoclave provides no guarantee of sterility. Using these materials under the assumption they are sterile can lead to contamination, experiment failure, or, in a clinical setting, severe infection.

Making the Right Choice for Your Goal

Always refer to the manufacturer's instructions for any instrument. When that is not possible, use these principles to guide your decision between steam autoclaving and alternative methods.

- If your primary focus is sterilizing glassware, liquids, or robust stainless steel instruments: The autoclave is the most effective, reliable, and economical method available.

- If your primary focus is sterilizing sharp carbon-steel tools or powders: Use dry heat sterilization, which sterilizes with hot air and avoids the corrosive effects of moisture.

- If your primary focus is sterilizing heat-sensitive plastics or delicate electronics: You must use low-temperature methods like ethylene oxide (EtO) gas, hydrogen peroxide plasma, or irradiation.

Matching the material to the method is the foundation of effective and safe sterilization.

Summary Table:

| Category | Examples of Non-Autoclavable Items | Reason |

|---|---|---|

| Heat-Sensitive Materials | Most plastics (PVC, polystyrene), electronics, biologicals | Will melt, warp, or degrade at 121°C (250°F) |

| Moisture-Damaged Materials | High-carbon steel scalpels, scissors | Steam causes corrosion and dulls sharp edges |

| Hydrophobic Substances | Oils, fats, powders, waxes | Steam cannot penetrate, leaving microbes alive |

| Sealed Containers | Air-tight, waterproof containers | Steam cannot reach the contents inside |

Need help selecting the right sterilization equipment for your lab's unique materials?

KINTEK specializes in providing reliable lab equipment and consumables tailored to your specific needs. Whether you require autoclaves for glassware and stainless steel or guidance on alternative sterilization methods for sensitive items, our experts are here to help you maintain efficiency and safety.

Contact our team today for a personalized consultation and ensure your sterilization processes are both effective and equipment-friendly!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory Horizontal Autoclave Steam Sterilizer Lab Microcomputer Sterilizer

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the size of a laboratory autoclave? A Guide to Choosing the Right Capacity

- What are the conditions for autoclave in microbiology? Achieve Sterile Lab Materials with Confidence

- What is the maintenance schedule for an autoclave? Ensure Sterilization Safety & Maximize Equipment Life

- How long is the sterilization cycle in an autoclave? It's More Than Just 15 Minutes

- What are the settings for autoclave sterilization? Ensure Reliable Sterility with Proper Parameters

- What is the application of retort machine in food industry? Ensuring Shelf-Stable Food Safety and Longevity

- What is the best and safest method of sterilization? Choose the Right Method for Your Materials and Safety

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization