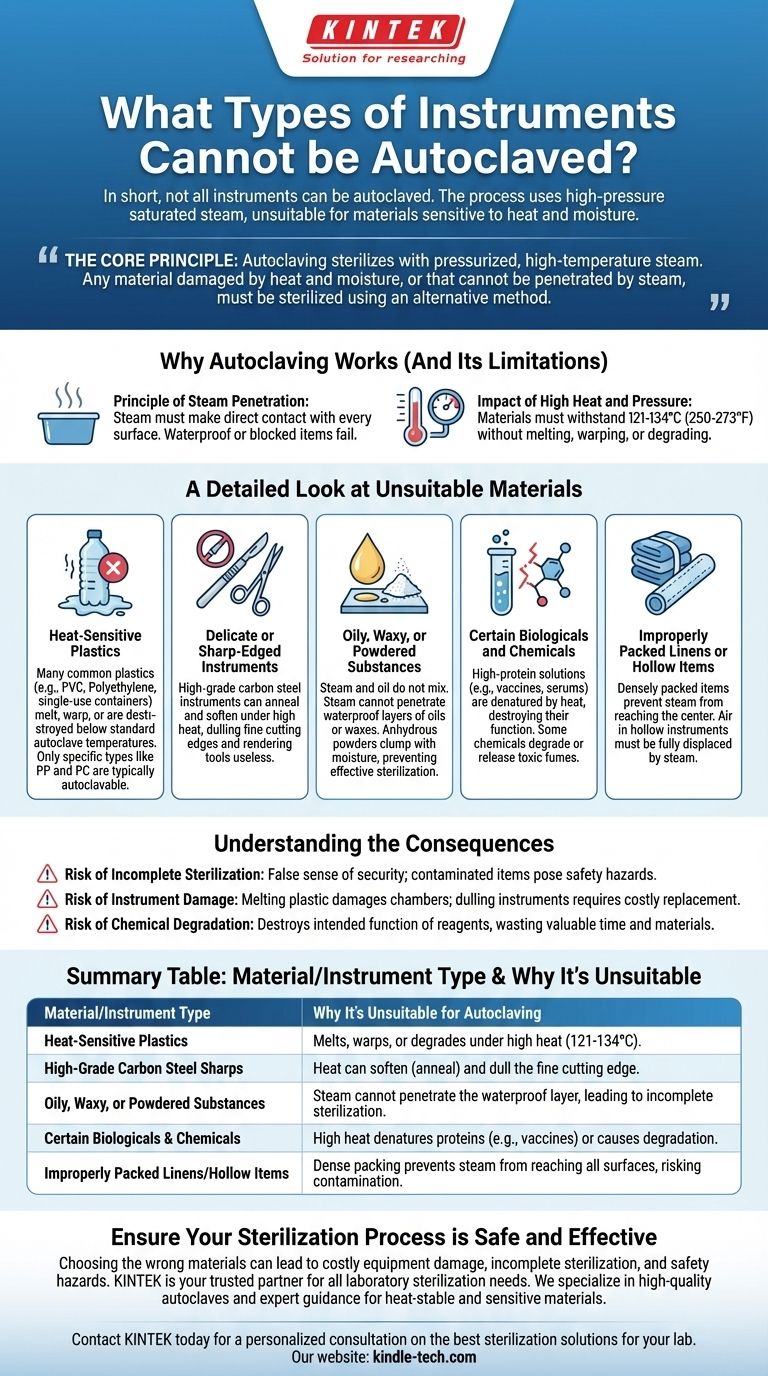

In short, not all instruments can be autoclaved. The process uses high-pressure saturated steam, making it unsuitable for any material that is sensitive to heat and moisture. This includes many plastics, high-grade carbon steel sharps, oily or waterproof substances, and certain biological or chemical solutions that degrade under high temperatures.

The core principle is simple: An autoclave sterilizes with pressurized, high-temperature steam. Therefore, any material that can be damaged by heat and moisture, or that cannot be penetrated by steam, must be sterilized using an alternative method.

Why Autoclaving Works (And Its Limitations)

An autoclave is essentially a highly controlled pressure cooker. It forces steam at temperatures around 121-134°C (250-273°F) onto the items inside, effectively killing all microorganisms, including resilient bacterial spores. This process relies on two critical factors.

The Principle of Steam Penetration

For sterilization to be successful, steam must make direct contact with every surface of the instrument. If a material is waterproof or packaged in a way that blocks steam, the process will fail.

The Impact of High Heat and Pressure

The materials being sterilized must be able to withstand intense heat and pressure without melting, warping, or degrading. This requirement immediately disqualifies a wide range of common lab and medical materials.

A Detailed Look at Unsuitable Materials

Understanding why a material is unsuitable is key to preventing equipment damage and ensuring effective sterilization.

Heat-Sensitive Plastics

Many common plastics have a melting point below the standard operating temperatures of an autoclave. Items like polyethylene, PVC, and most single-use plastic containers will warp, melt, or be destroyed.

Only specific types of plastics, such as polypropylene (PP) and polycarbonate (PC), are typically autoclavable. Always check for a manufacturer's rating.

Delicate or Sharp-Edged Instruments

While stainless steel surgical tools are ideal for autoclaving, high-grade carbon steel instruments are not. The high heat can anneal, or soften, the fine cutting edge of scalpels and high-quality scissors, rendering them dull.

Oily, Waxy, or Powdered Substances

Steam and oil do not mix. Attempting to autoclave oily substances or instruments coated in oil is ineffective because the steam cannot penetrate the waterproof layer to reach and kill the microorganisms.

Similarly, anhydrous powders are unsuitable as the moisture can cause them to clump and will not effectively sterilize the material.

Certain Biologicals and Chemicals

High-protein solutions, such as vaccines, serums, or some enzymes, will be denatured and destroyed by the excessive heat. The sterilization process would render them biologically useless.

Certain chemicals can also degrade or release toxic fumes under high heat and pressure, making them unsafe for autoclaving.

Improperly Packed Linens or Hollow Items

While fabrics and linens are often autoclaved, they can be a point of failure. If they are packed too densely, steam cannot penetrate the center of the bundle, leaving it non-sterile.

The same principle applies to hollow instruments; air must be fully displaced by steam for the inner surfaces to be sterilized.

Understanding the Consequences

Attempting to autoclave unsuitable materials leads to predictable and costly problems.

Risk of Incomplete Sterilization

The most significant risk is creating a false sense of security. Autoclaving an item that steam cannot penetrate, like an oily instrument, means it will emerge from the process still contaminated, posing a safety hazard.

Risk of Instrument Damage

Melting plastic can not only destroy the item but can also damage the autoclave chamber itself. Dulling sharp instruments renders expensive tools useless and requires costly sharpening or replacement.

Risk of Chemical Degradation

For lab work, autoclaving a solution like a protein serum or antibiotic doesn't just sterilize it—it destroys its intended function, wasting time and valuable reagents.

Choosing the Right Sterilization Method

Making the correct choice is critical for both safety and preserving the value of your equipment.

- If you are sterilizing heat-stable, non-corrosive instruments (like stainless steel): The autoclave is the most reliable and effective method.

- If you are sterilizing heat-sensitive plastics or electronics: Consider alternatives like Ethylene Oxide (EtO) gas, vaporized hydrogen peroxide (VHP), or gamma irradiation.

- If you are sterilizing sharp carbon-steel instruments: Dry heat sterilization is a common alternative that avoids moisture and reduces the risk of dulling the edge.

- If you are sterilizing oils, waxes, or powders: Dry heat is the required method, as steam penetration is impossible.

Ultimately, understanding the limits of autoclaving is fundamental to maintaining a safe and effective sterile environment.

Summary Table:

| Material/Instrument Type | Why It's Unsuitable for Autoclaving |

|---|---|

| Heat-Sensitive Plastics (e.g., PVC, Polyethylene) | Melts, warps, or degrades under high heat (121-134°C). |

| High-Grade Carbon Steel Sharps | Heat can soften (anneal) and dull the fine cutting edge. |

| Oily, Waxy, or Powdered Substances | Steam cannot penetrate the waterproof layer, leading to incomplete sterilization. |

| Certain Biologicals & Chemicals | High heat denatures proteins (e.g., vaccines) or causes degradation. |

| Improperly Packed Linens/Hollow Items | Dense packing prevents steam from reaching all surfaces, risking contamination. |

Ensure Your Sterilization Process is Safe and Effective

Sterilizing the wrong materials can lead to costly equipment damage, incomplete sterilization, and safety hazards. Choosing the right method is critical for lab safety and efficiency.

KINTEK is your trusted partner for all laboratory sterilization needs. We specialize in providing not only high-quality autoclaves but also the expert guidance to help you select the right equipment and methods for your specific applications—whether you're working with heat-stable stainless steel or sensitive materials that require alternative sterilization techniques.

Let our experts help you protect your investment and ensure compliance. We serve a wide range of laboratory needs, from research institutions to pharmaceutical companies.

Contact KINTEK today for a personalized consultation on the best sterilization solutions for your lab.

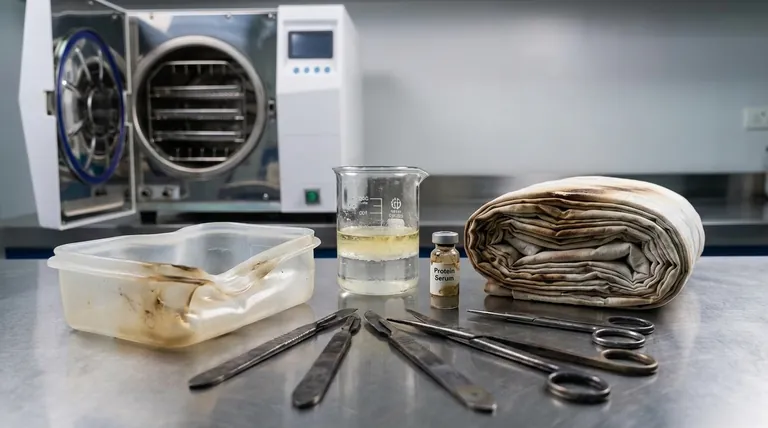

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What physical conditions does an autoclave provide during hydrothermal liquefaction? Unlock Superior Bio-Polyol Yields

- How do you use an autoclave in a microbiology lab? Master Sterilization for Lab Safety & Accuracy

- What is the temperature of autoclave 132? A Guide to High-Speed Sterilization Cycles

- What is the use of autoclave in microbiology? Ensuring Sterile Conditions for Reliable Results

- How do you use autoclave in microbiology? A Guide to Absolute Sterilization for Lab Safety

- How does an autoclave sterilize instruments supplies and equipment? A Guide to High-Pressure Steam Sterilization

- What is the difference between autoclave types? Choose the Right Sterilizer for Your Lab

- Do autoclaves use a lot of electricity? Managing Energy Costs in Your Sterilization Process