In short, 121°C is the universal standard for autoclaving because it is the scientifically proven minimum temperature required to destroy the most heat-resistant microorganisms known: bacterial spores. This temperature, when combined with pressurized steam for a specific duration, ensures the complete inactivation of all forms of microbial life, achieving true sterility.

The goal of autoclaving isn't just to disinfect, but to sterilize—meaning the elimination of all living organisms. The 121°C standard is not an arbitrary number; it is the precise thermal point required to overcome the extreme defenses of bacterial spores, the final boss of microbiology.

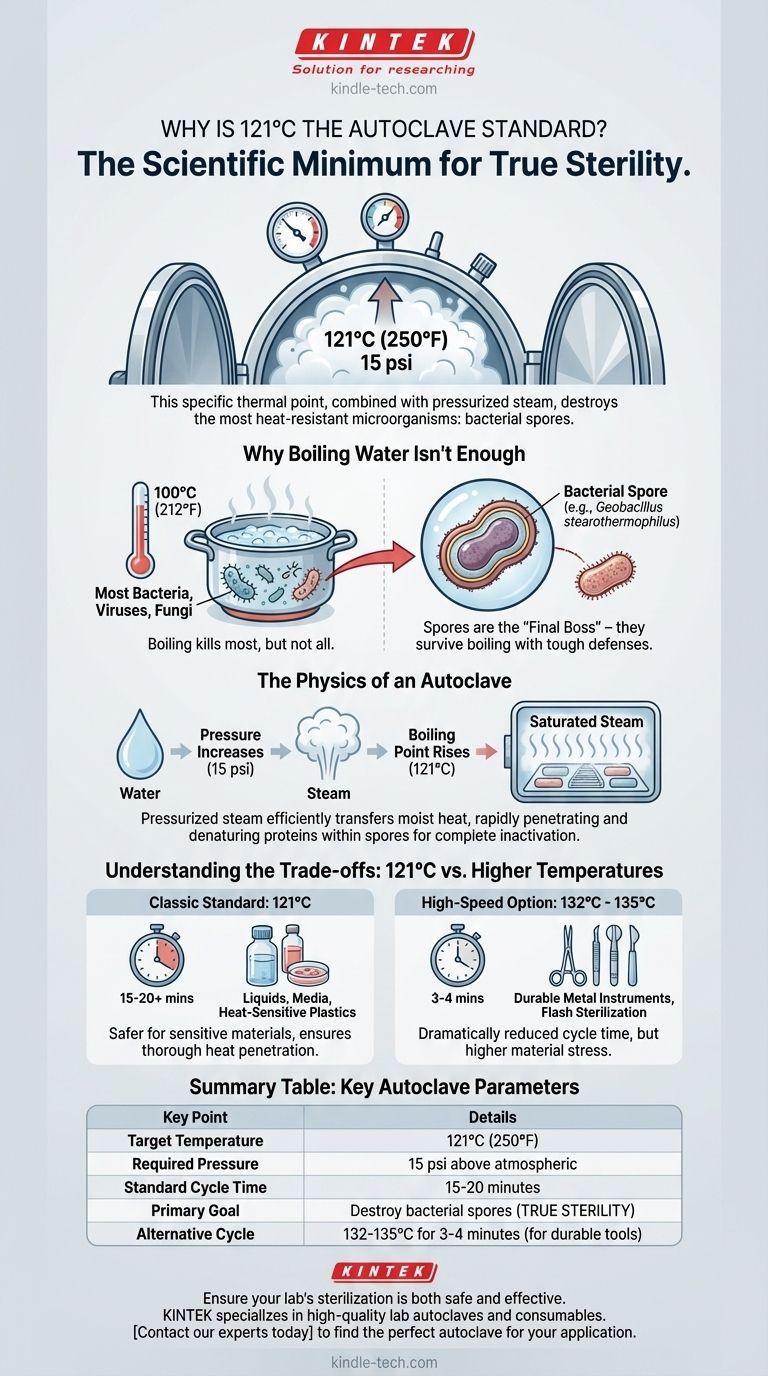

Why Boiling Water Isn't Enough

The Resilience of Bacterial Spores

Most bacteria, viruses, and fungi are easily killed by boiling water at 100°C (212°F). However, some bacteria can form dormant, highly protected structures called spores when conditions are unfavorable.

These spores have tough outer coatings and dehydrated cores, making them incredibly resistant to heat, chemicals, and radiation. They can survive boiling for extended periods.

The Benchmark for Sterility

To ensure true sterility, the process must be validated against the most difficult-to-kill organism. In steam sterilization, this is typically the spore of Geobacillus stearothermophilus, which is exceptionally heat-resistant.

Scientific validation has shown that exposure to 121°C is the critical threshold needed to reliably destroy these spores.

The Physics of an Autoclave

Pressurized Steam is the Key

At standard atmospheric pressure, water boils at 100°C. To reach a higher temperature, you must increase the pressure. This is the fundamental principle of an autoclave.

An autoclave is essentially a high-tech pressure cooker. By increasing the internal pressure to approximately 15 pounds per square inch (psi) above atmospheric pressure, it raises the boiling point of water to 121°C.

The Role of Saturated Steam

At this temperature and pressure, the autoclave chamber fills with saturated steam. This moisture is crucial because it efficiently transfers thermal energy to the items being sterilized.

The moist heat rapidly penetrates materials and denatures the essential proteins and enzymes within the spores, leading to their inactivation. Dry heat is far less effective and requires much higher temperatures and longer times.

Understanding the Trade-offs: 121°C vs. Higher Temperatures

The Classic Standard: 121°C

The standard cycle is 121°C at 15 psi for at least 15-20 minutes, depending on the size and type of the load. This method is effective, well-studied, and safer for a wider range of materials.

It is the preferred temperature for sterilizing liquids, media, and some plastics that could be damaged by higher temperatures.

The High-Speed Option: 132°C to 135°C

Many modern autoclaves also operate at higher temperatures, such as 132-135°C (270-273°F). This requires a higher pressure (around 30 psi).

The primary benefit of a higher temperature is a dramatically reduced cycle time, often just 3-4 minutes. This is ideal for "flash sterilization" of unwrapped, robust instruments like metal surgical tools in a hospital setting where speed is critical.

Choosing the Right Temperature

The trade-off is between time and material compatibility. While faster, the 135°C cycle generates more stress on materials and is unsuitable for most liquids (which would boil over) or heat-sensitive instruments.

Making the Right Choice for Your Goal

Selecting the correct autoclave cycle is critical for ensuring both sterility and the integrity of your equipment.

- If your primary focus is sterilizing liquids, laboratory media, or heat-sensitive plastics: Use the standard 121°C cycle, allowing sufficient time for heat to penetrate the entire load.

- If your primary focus is rapidly sterilizing durable metal instruments (e.g., surgical tools): A higher temperature cycle of 132-135°C is more efficient and appropriate.

- If you are sterilizing dense loads or wrapped instrument packs: You must increase the cycle time at 121°C to ensure the steam fully penetrates to the center of the pack.

Understanding the principles behind the 121°C standard empowers you to make sterilization decisions that are both safe and effective.

Summary Table:

| Key Point | Details |

|---|---|

| Target Temperature | 121°C (250°F) |

| Required Pressure | 15 psi above atmospheric pressure |

| Standard Cycle Time | 15-20 minutes |

| Primary Goal | Destroy bacterial spores (e.g., Geobacillus stearothermophilus) for true sterility |

| Alternative Cycle | 132-135°C for 3-4 minutes (flash sterilization for durable instruments) |

Ensure your lab's sterilization is both safe and effective. Choosing the right autoclave and cycle is critical for protecting your research and equipment integrity. KINTEK specializes in high-quality lab autoclaves and consumables, providing reliable solutions tailored to your specific laboratory needs—from sterilizing sensitive media with standard cycles to rapid processing of instruments. Contact our experts today to find the perfect autoclave for your application and achieve guaranteed sterility.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- Why do we autoclave at 121 degree Celsius? The Science Behind Sterilization

- What types of instruments Cannot be autoclaved? Protect Your Lab Equipment from Damage

- What is the role of autoclave in sterilization? Achieve Absolute Sterilization with High-Pressure Steam

- What is the protocol for autoclave machine? A Step-by-Step Guide to Safe Sterilization

- What are the handling procedures of autoclave? A Step-by-Step Guide to Safe Sterilization

- What is the temperature of autoclave 132? A Guide to High-Speed Sterilization Cycles

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing

- What is the pressure required in an autoclave? Achieve Sterile Results with 15 PSI