The short answer is an autoclave, or pressure cooker, uses steam under pressure to kill microorganisms far more effectively and rapidly than dry heat. The presence of water fundamentally changes how heat energy is transferred, making it a powerful sterilization agent at lower temperatures and in shorter times.

While both methods use high temperatures, an autoclave leverages pressurized steam to rapidly transfer lethal energy and chemically break down microbial proteins. Dry heat, in contrast, relies on a much slower "baking" process of oxidation that requires significantly higher temperatures and longer exposure times to achieve the same result.

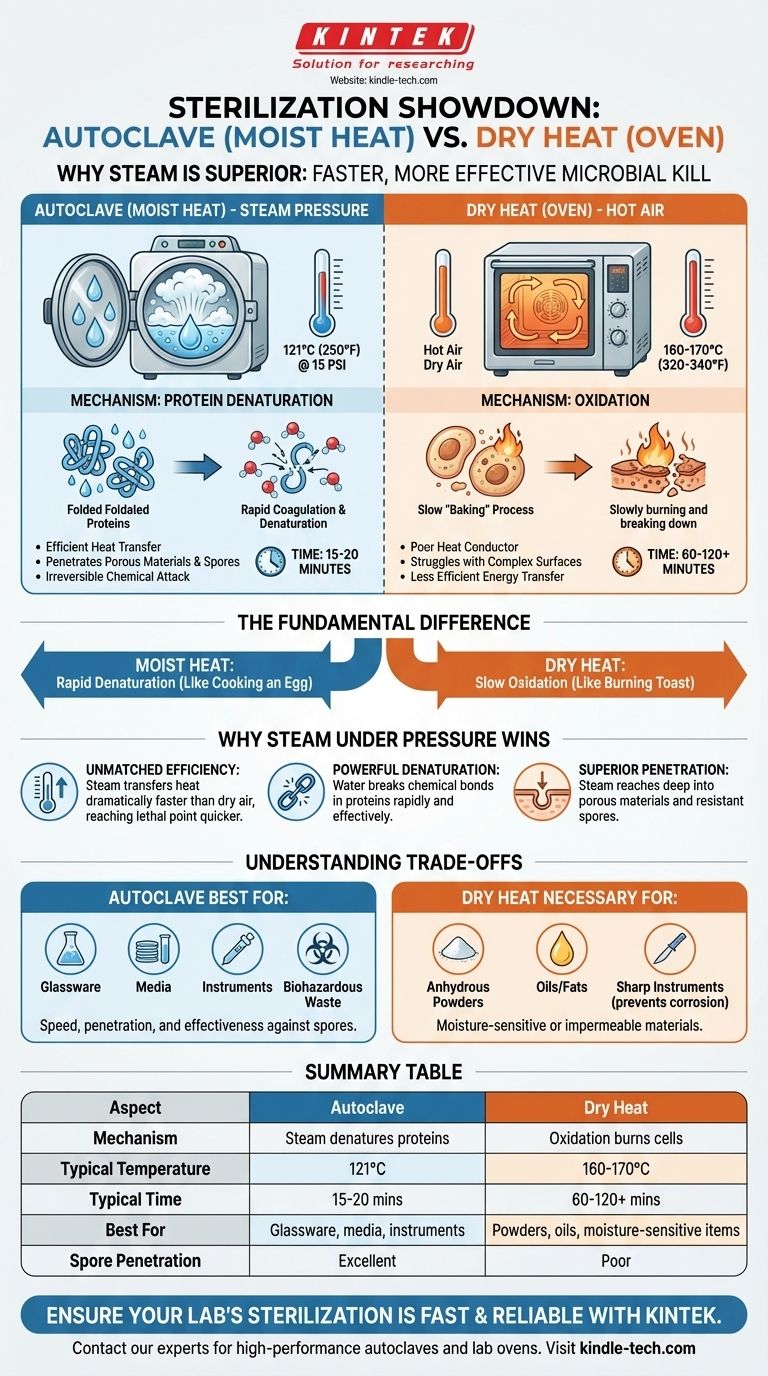

The Fundamental Difference: How Heat Kills

To understand the difference in effectiveness, you must first understand the two distinct mechanisms by which these methods destroy life.

The Mechanism of Moist Heat (Autoclave)

An autoclave works by creating steam and then increasing the pressure within a sealed chamber. This pressure allows the steam to reach temperatures far above the normal boiling point of water, typically 121°C (250°F) at 15 PSI.

The key to moist heat's effectiveness is the water vapor itself. This steam efficiently transfers thermal energy to microorganisms, causing their essential proteins to rapidly coagulate and denature.

This process is a chemical attack that irreversibly destroys the shape and function of proteins and enzymes, leading to swift cell death.

The Mechanism of Dry Heat (Oven)

Dry heat sterilization, typically done in a specialized oven, uses hot, dry air to kill microbes. This method is essentially a process of oxidation.

Think of it as slowly cooking or "baking" the microorganisms to death. It's a much less efficient process than the rapid denaturation caused by steam.

Because air is a poor conductor of heat compared to steam, dry heat requires much higher temperatures—often 160°C to 170°C (320°F to 340°F)—and significantly longer exposure times, frequently 60 to 120 minutes or more.

Why Steam Under Pressure is Superior

The advantage of an autoclave comes down to physics and chemistry. Pressurized steam is not just "hotter"; it is a fundamentally more aggressive sterilizing agent.

Unmatched Heat Transfer Efficiency

Steam is a dramatically more efficient vehicle for heat transfer than dry air. A microorganism exposed to steam at 121°C will have its temperature raised to the lethal point much faster than one exposed to dry air at 170°C.

This rapid energy transfer ensures that the entire object being sterilized, including the microorganisms on it, reaches the target temperature quickly and uniformly.

The Power of Protein Denaturation

Moist heat kills by denaturation, a process where water molecules help break the chemical bonds that hold proteins in their functional three-dimensional shape. This process is extremely rapid and effective.

Dry heat kills by oxidation, a slower process that essentially burns the cellular components. It requires more energy (higher temperature and longer time) to achieve the same lethal outcome.

Penetration Power

Pressurized steam has a superior ability to penetrate porous materials, dense instrument packs, and the tough protective coats of bacterial spores. Dry air struggles to transfer heat into these complex surfaces, risking incomplete sterilization.

Understanding the Trade-offs and Exceptions

While autoclaving is superior for general sterilization, it is not the correct choice for every situation. An expert knows when to use the right tool.

When Dry Heat is Necessary

Dry heat is the required method for materials that are either sensitive to moisture or impermeable to steam.

This includes substances like anhydrous powders, fats, and oils. It is also preferred for certain sharp metal instruments, as the high moisture in an autoclave can cause corrosion and dulling over time.

The Limitations of Autoclaves

Autoclaves cannot be used for water-sensitive materials. Furthermore, improper loading can trap air, creating "cold spots" where steam cannot reach and sterilization fails.

Certain metals may corrode under repeated exposure to high-pressure steam, making dry heat a better option for preserving the life of the instrument.

Comparing Time and Energy

For most applications, an autoclave is significantly faster. A standard autoclave cycle might run for 15-20 minutes at 121°C, while a dry heat cycle needs at least 60 minutes at 170°C.

This speed makes autoclaving more efficient for high-throughput environments like hospitals and laboratories, often consuming less total energy per cycle despite the complexity of the machine.

Making the Right Choice for Your Goal

Your choice of sterilization method must be based on the material you are treating and your primary objective.

- If you are sterilizing most lab media, glassware, or surgical instruments: Use an autoclave for its unmatched speed, penetration, and effectiveness against even the most resistant spores.

- If you are sterilizing powders, oils, or sharp instruments prone to corrosion: Use a dry heat oven, and ensure you validate the longer time and higher temperature required for sterility.

- If your primary goal is the guaranteed destruction of all microbial life: The autoclave is the gold standard due to its rapid and effective protein denaturation, but only if the material is compatible with steam.

Ultimately, understanding the mechanism—denaturation versus oxidation—is the key to making an informed and effective sterilization decision.

Summary Table:

| Aspect | Autoclave (Moist Heat) | Dry Heat (Oven) |

|---|---|---|

| Mechanism | Steam denatures proteins | Oxidation burns cells |

| Typical Temperature | 121°C (250°F) | 160–170°C (320–340°F) |

| Typical Time | 15–20 minutes | 60–120+ minutes |

| Best For | Glassware, media, instruments | Powders, oils, moisture-sensitive items |

| Spore Penetration | Excellent | Poor |

Ensure your lab's sterilization is fast, effective, and reliable.

Choosing the right equipment is critical for safety and efficiency. KINTEK specializes in high-performance autoclaves and lab ovens designed to meet the rigorous demands of modern laboratories. Our autoclaves deliver rapid, penetrating steam sterilization, while our dry heat ovens provide precise control for sensitive materials.

Let us help you select the perfect sterilization solution for your specific needs. Contact our experts today to discuss how KINTEK's lab equipment can enhance your workflow and ensure uncompromising sterility.

Visual Guide

Related Products

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What are the advantages of using a large-capacity autoclave for the secondary curing of calcium silicate specimens?

- What is the protocol for sterilization of glassware? A Step-by-Step Guide to Lab-Ready Sterility

- What is the main purpose of the autoclave? Achieve Complete Sterilization with High-Pressure Steam

- What are the safety concerns when autoclaving? A Guide to Preventing Burns, Explosions, and Biohazards

- Why use a Teflon-lined stainless steel autoclave for TiO2 nanobelts? Achieve Extreme Chemical & Pressure Resistance

- What are the four components of sterilization? Master the Pillars of Effective Sterilization

- What is the temperature above 100 for autoclaving? Achieve Sterilization at 121°C

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility