An autoclave is the most effective sterilizer because it leverages the power of high-pressure steam to achieve temperatures far exceeding the boiling point of water. This combination of intense, moist heat is uniquely capable of rapidly penetrating and irreversibly destroying all forms of microbial life, from simple bacteria to highly resistant spores.

The true power of an autoclave lies not just in its heat, but in the use of pressurized, moist steam. This moisture is the critical agent that efficiently transfers thermal energy to coagulate microbial proteins, a process far more effective and rapid than dry heat alone.

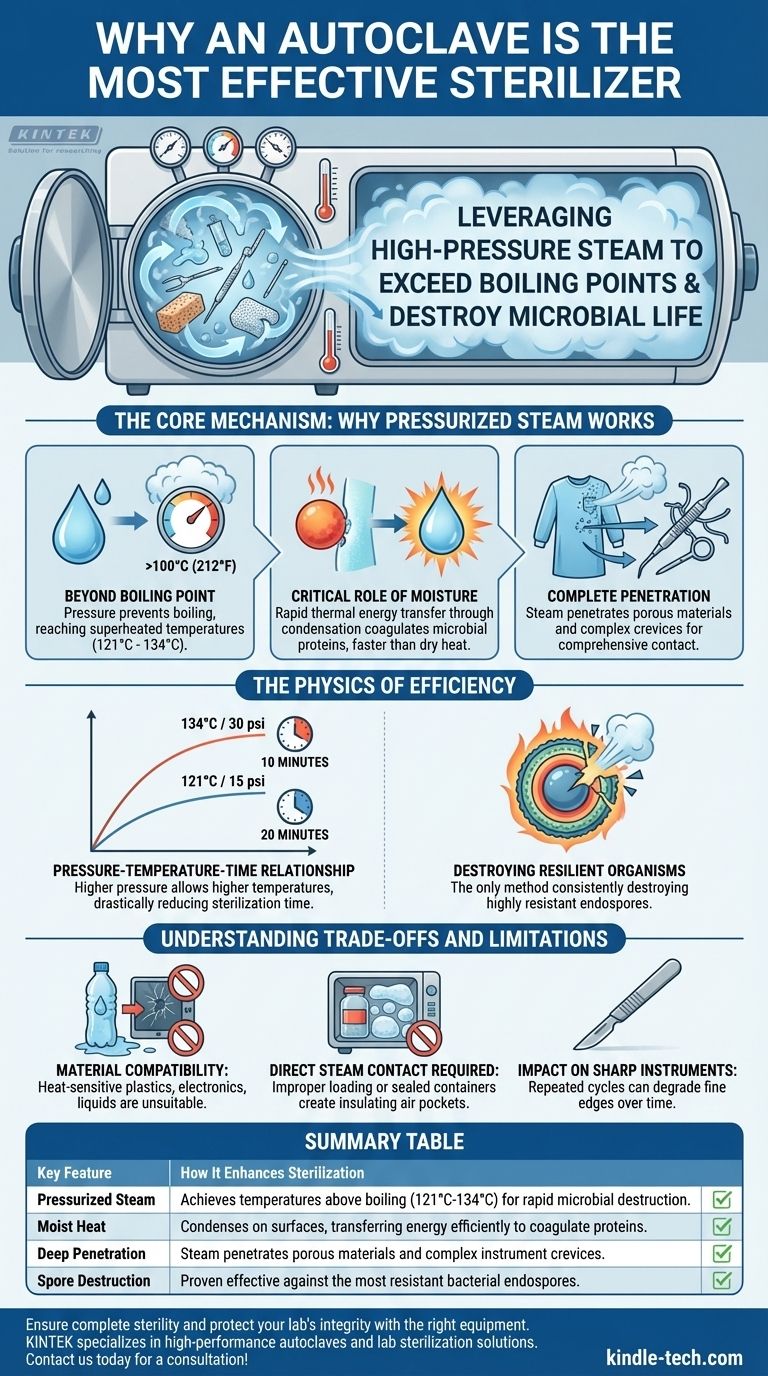

The Core Mechanism: Why Pressurized Steam Works

To understand the autoclave's effectiveness, you must look beyond simple heat and focus on the physics of pressurized steam.

Beyond Boiling Point

At standard atmospheric pressure, water boils at 100°C (212°F). By increasing the pressure inside a sealed chamber, an autoclave prevents water from boiling, allowing it to reach much higher temperatures while remaining in a gaseous state (steam).

This superheated steam is the primary sterilization agent.

The Critical Role of Moisture

The moisture within the steam is the key to its efficiency. When this hot vapor makes contact with a cooler item, it immediately condenses into liquid water, rapidly transferring a massive amount of thermal energy.

This process, known as moist heat sterilization, denatures and coagulates the essential proteins within microorganisms. This is fundamentally different and much faster than dry heat, which slowly oxidizes cells from the outside.

Complete Penetration and Contact

Pressurized steam can effectively penetrate porous materials like surgical gowns and reach every surface of complex instruments. This ensures that no microorganisms can hide in crevices, a common point of failure for other sterilization methods.

The Physics of Autoclave Efficiency

The relationship between pressure, temperature, and time is the foundation of reliable autoclave cycles.

The Pressure-Temperature-Time Relationship

Higher pressure allows for higher steam temperatures, which in turn drastically reduces the time required for complete sterilization. This is a predictable and measurable relationship.

For example, a common cycle runs at 121°C (250°F) under approximately 108 kPa (15 psi) of pressure, requiring about 20 minutes for sterilization.

By increasing the pressure to roughly 206 kPa (30 psi), the temperature rises to 134°C (273°F), and the required sterilization time can drop to as little as 10 minutes.

Destroying the Most Resilient Organisms

The ultimate test of any sterilization method is its ability to kill bacterial endospores. These are dormant, highly protected structures that some bacteria form to survive extreme environmental stress, including heat and chemicals.

The combination of saturated steam and high temperatures in an autoclave is one of the few methods proven to consistently destroy these resilient spores, making it the benchmark for sterility assurance in medical and laboratory settings.

Understanding the Trade-offs and Limitations

While highly effective, an autoclave is not a universal solution. Understanding its limitations is critical for proper use.

Not All Materials are Suitable

The high heat and pressure will destroy or damage many materials. Heat-sensitive plastics, certain electronics, and liquids that cannot withstand these temperatures require alternative sterilization methods.

The Requirement of Direct Steam Contact

Sterilization will fail if steam cannot make direct contact with every surface. Improper loading, such as overpacking the chamber or using sealed containers, creates air pockets that insulate items from the steam.

Impact on Sharp Instruments

Repeated autoclaving can dull the fine edges of sharp surgical instruments. While they will be sterile, their performance may degrade over time.

Making the Right Choice for Your Goal

To apply this knowledge effectively, align the sterilization method with your specific item and objective.

- If your primary focus is complete microbial eradication for durable goods: The autoclave's use of pressurized steam is the undisputed gold standard for destroying even the toughest bacterial spores.

- If you are sterilizing heat-sensitive items: You must consider alternative low-temperature methods like ethylene oxide (EtO) gas or hydrogen peroxide plasma sterilization, as an autoclave will cause damage.

- If you want to ensure consistent, valid results: Proper loading techniques are non-negotiable; you must allow for steam penetration and avoid overpacking the chamber to prevent sterilization failure.

Understanding these core principles empowers you to use the autoclave not just as a machine, but as a precision instrument for guaranteed sterility.

Summary Table:

| Key Feature | How It Enhances Sterilization |

|---|---|

| Pressurized Steam | Achieves temperatures above boiling (121°C-134°C) for rapid microbial destruction. |

| Moist Heat | Condenses on surfaces, transferring energy efficiently to coagulate proteins. |

| Deep Penetration | Steam penetrates porous materials and complex instrument crevices. |

| Spore Destruction | Proven effective against the most resistant bacterial endospores. |

Ensure complete sterility and protect your lab's integrity with the right equipment. KINTEK specializes in high-performance autoclaves and lab sterilization solutions designed for reliability and efficiency. Our experts can help you select the perfect autoclave to meet your specific laboratory needs. Contact us today for a consultation and enhance your lab's safety protocol!

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- Is autoclave a lab equipment? Essential Sterilization for Reliable Science

- Is autoclave effective on all organisms? The Definitive Guide to Sterilization Limits

- Why are high-pressure hydrothermal autoclaves essential for IrRu@Te synthesis? Achieve Peak Catalyst Stability

- What is the time required for autoclaving at 121 C? A Guide to Sterilization Cycles

- How do you use an autoclave in a microbiology lab? Master Sterilization for Lab Safety & Accuracy

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What is the temperature used for autoclaving of microorganisms? Achieve Reliable Sterilization in Your Lab

- What is the maintenance schedule for an autoclave? Ensure Sterilization Safety & Maximize Equipment Life