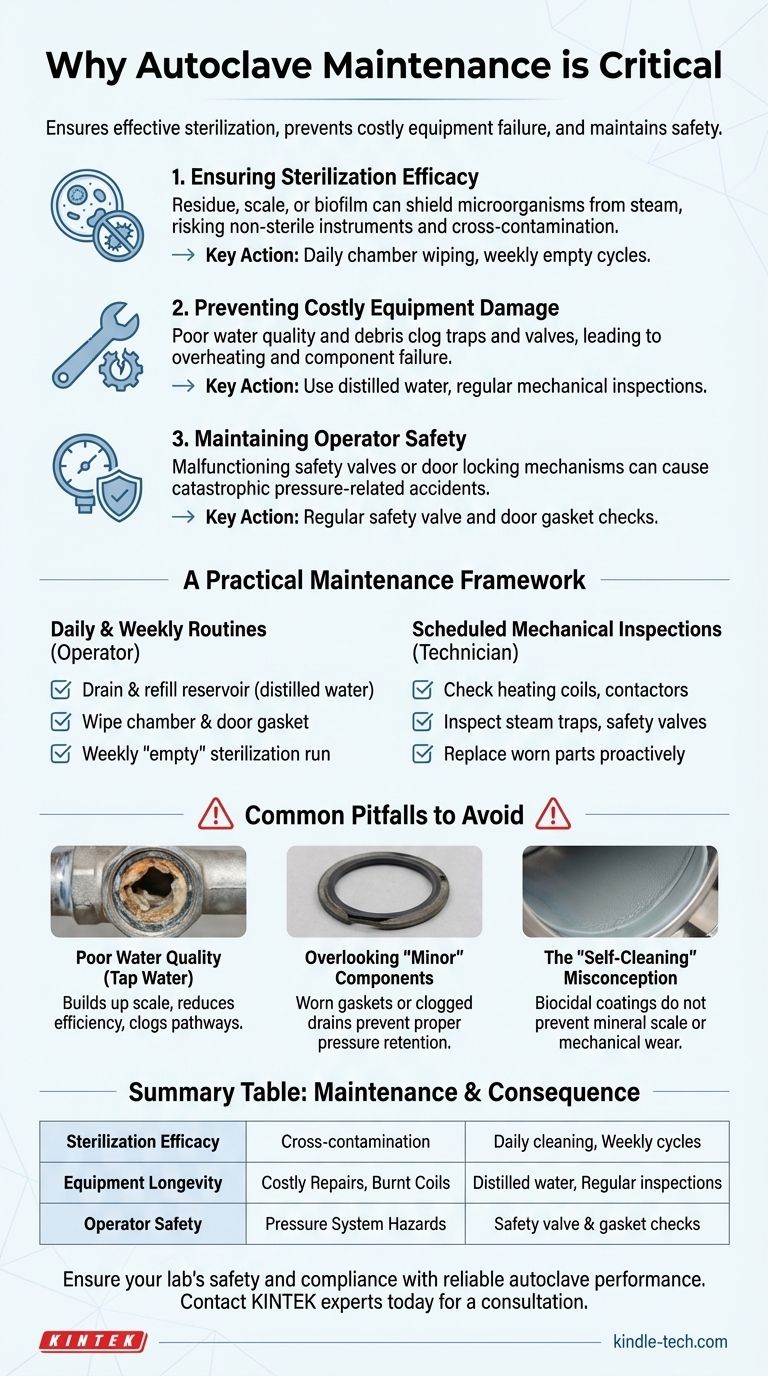

Proper autoclave maintenance and cleaning are critical for three primary reasons: ensuring sterilization is actually effective, preventing premature and costly equipment failure, and maintaining a safe operating environment. Neglecting these duties can lead to contaminated instruments, damaged components, and potential safety hazards from malfunctioning pressure systems.

The core issue is that an autoclave's performance is not guaranteed; it is earned. Consistent maintenance is the only way to ensure the machine can reliably create the precise conditions of steam, pressure, and temperature required to achieve true sterility, cycle after cycle.

The Core Pillars of Autoclave Integrity

To understand the importance of maintenance, we must look beyond surface cleanliness and examine the fundamental processes that can be compromised by neglect.

Ensuring Sterilization Efficacy

The entire purpose of an autoclave is to sterilize. Any residue, mineral deposits, or biofilm inside the chamber can shield microorganisms from the superheated steam.

This creates a situation where the cycle completes and appears successful, but the instruments inside may not be truly sterile, creating a significant risk of cross-contamination.

Preventing Costly Equipment Damage

Autoclaves are precision instruments operating under extreme conditions. Poor water quality and accumulated debris are their primary enemies.

Particulates and mineral scale from unfiltered water can clog steam traps, solenoid valves, and drain lines. This buildup can also coat heating coils, forcing them to work harder and eventually burn out.

A simple worn door gasket can prevent the chamber from achieving the required pressure, leading to aborted cycles and eventual damage to the sealing surface. These are not minor issues; they are precursors to major repairs.

Maintaining Operator Safety

An autoclave is a pressurized vessel. Its safety features, such as the safety valve and door locking mechanisms, must be in perfect working order.

Debris can interfere with the proper function of these components. Regular inspection ensures that these critical safety systems will function correctly, preventing catastrophic failures that could harm personnel.

A Practical Maintenance Framework

Effective maintenance is not a single event but a consistent schedule of distinct tasks. This schedule can be broken down by frequency.

Daily and Weekly Cleaning Routines

These tasks are typically performed by the operator and are foundational to reliable performance.

In a clinical setting, this includes draining and refilling the water reservoir daily with distilled or deionized water to prevent mineral buildup.

The internal chamber and the door gasket should also be wiped down to remove any residue. A weekly "empty" sterilization run helps clean out any internal plumbing and hard-to-reach areas.

Scheduled Mechanical Inspections

These deeper checks are often performed by trained technicians on a monthly, quarterly, or annual basis.

Inspections focus on the functional components of the machine, including the heating coils, contactors, steam traps, and safety valves.

This proactive approach identifies parts that are worn or nearing failure, allowing for replacement before they can cause a system-wide breakdown.

Common Pitfalls to Avoid

Even with a maintenance plan, certain oversights can undermine your efforts and lead to significant problems.

The Hidden Cost of Poor Water Quality

Using tap water is perhaps the single most damaging yet common mistake. While it seems like a cost-saving measure, the dissolved minerals build up as hard scale inside the machine.

This scale reduces heating efficiency, clogs critical pathways, and ultimately leads to expensive descaling procedures or component replacement, far outweighing the cost of using distilled water.

Overlooking 'Minor' Components

A worn door gasket or a slightly clogged chamber drain can seem insignificant. However, these "minor" issues directly impact the autoclave's ability to generate and hold pressure.

This prevents the cycle from ever reaching the validated parameters for sterilization, rendering the entire process ineffective even if the machine doesn't report an error.

The 'Self-Cleaning' Misconception

Some modern autoclaves feature advanced coatings with biocidal activity, which makes routine wipe-downs easier and more effective.

However, this feature should not be confused with a substitute for maintenance. These coatings do not prevent mineral scale from poor water quality, nor do they stop the mechanical wear and tear on valves, gaskets, and sensors.

Making the Right Choice for Your Goal

Your maintenance strategy should be directly aligned with your operational priorities.

- If your primary focus is clinical compliance and patient safety: Daily cleaning, daily water changes, and meticulous logging are non-negotiable to prevent any risk of cross-contamination.

- If your primary focus is research and data integrity: Consistent performance, guaranteed by regular maintenance, prevents failed sterilization cycles that could compromise or invalidate your experiments.

- If your primary focus is equipment lifespan and ROI: Proactive mechanical inspections and the exclusive use of high-quality water are the best investments you can make to avoid premature failure.

Ultimately, a well-maintained autoclave is the bedrock of a safe, effective, and reliable sterilization process.

Summary Table:

| Key Reason | Consequence of Neglect | Maintenance Action |

|---|---|---|

| Sterilization Efficacy | Cross-contamination from non-sterile instruments | Daily chamber wiping, weekly empty cycles |

| Equipment Longevity | Costly repairs from clogged valves or burnt coils | Use distilled water, regular mechanical inspections |

| Operator Safety | Hazards from malfunctioning pressure systems | Regular safety valve and door gasket checks |

Ensure your lab's safety and compliance with reliable autoclave performance. KINTEK specializes in laboratory equipment and consumables, providing the expertise and support to keep your autoclave—and your entire lab—running efficiently and safely. Don't let maintenance issues compromise your work. Contact our experts today for a consultation on your lab's sterilization needs.

Visual Guide

Related Products

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing

- What is the function of laboratory autoclaves in SCWR research? Predict Material Compatibility and Corrosion Kinetics

- What extreme conditions does a laboratory autoclave simulate? Testing Wear Resistance of Nuclear Fuel Cladding