In short, an autoclave uses 121°C because it is the scientifically established temperature required to reliably destroy the most heat-resistant life forms known: bacterial endospores. This is achieved by using pressurized steam, which transfers heat far more effectively than dry air, ensuring the complete sterilization of equipment and materials.

The specific temperature of 121°C isn't arbitrary; it's the result of a precise formula involving heat, pressure, and time. This combination is designed to kill the toughest microbial contaminants, providing a critical margin of safety for scientific and medical applications.

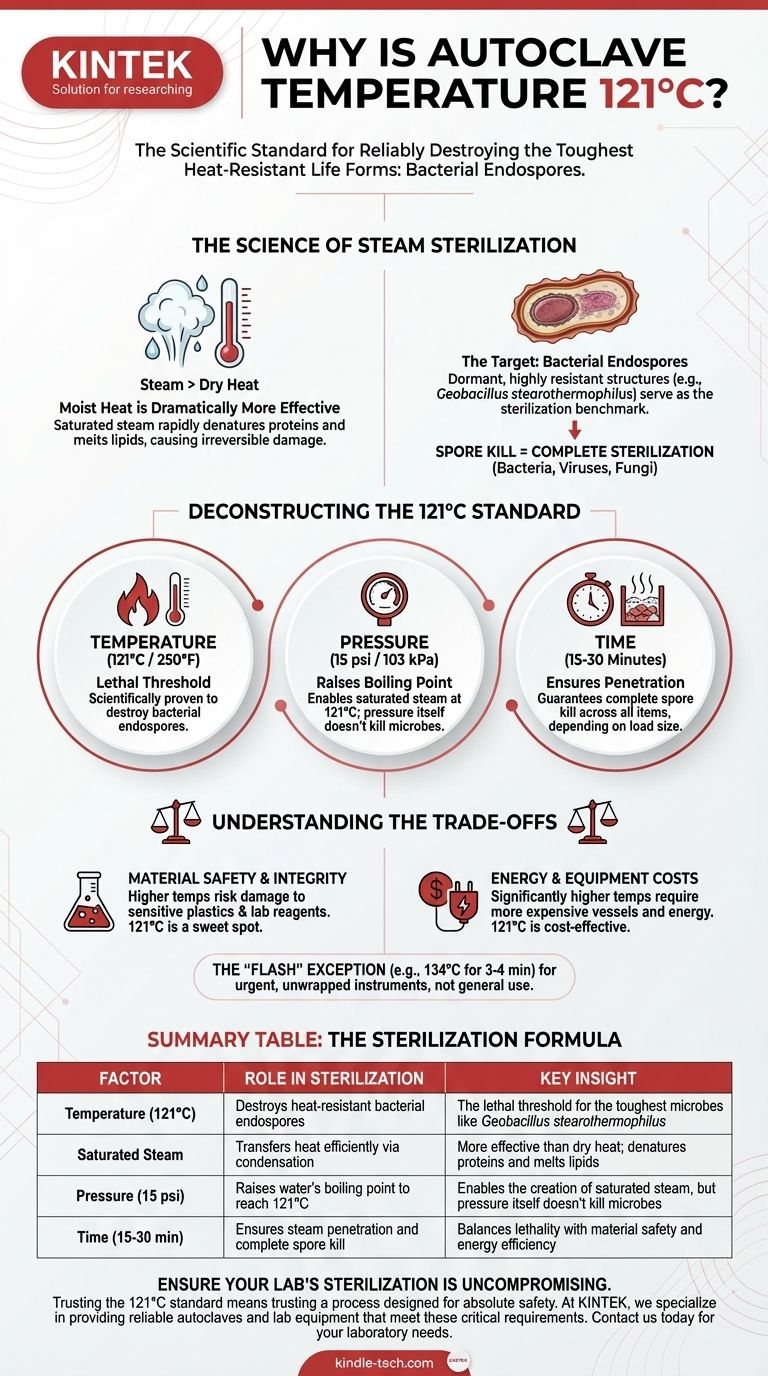

The Science of Steam Sterilization

To understand the 121°C standard, you must first understand that sterilization is not just about heat. It's about delivering lethal heat in the most efficient way possible to every surface.

Why Steam is More Effective Than Dry Heat

Moist heat is dramatically more effective at killing microorganisms than dry heat. Saturated steam rapidly denatures essential proteins and melts the lipids within microbial cells, causing irreversible damage and death.

Steam achieves this by transferring thermal energy with incredible efficiency. When steam condenses on a cooler object, it releases a large amount of energy (its latent heat of vaporization), rapidly heating the object's surface to the steam's temperature.

The Target: Bacterial Endospores

The goal of sterilization is to achieve a "Spore Kill"—the elimination of all bacterial endospores. These are dormant, highly resistant structures produced by certain bacteria, such as Geobacillus stearothermophilus, to survive extreme environmental stress.

Because they are the most difficult form of microbial life to destroy, endospores serve as the benchmark for sterilization. If your process can kill them, you can be confident it has also killed all other less-resistant bacteria, viruses, and fungi.

Deconstructing the 121°C Standard

The combination of 121°C, pressure, and time is engineered specifically to defeat these endospores with certainty. Each component plays a non-negotiable role.

Killing the Toughest Microbes

Scientific validation has proven that exposure to 121°C (250°F) saturated steam will destroy bacterial endospores. Holding a load at this temperature for a sufficient duration—typically 15 to 30 minutes, depending on the load size—ensures complete penetration and sterilization.

The Role of Pressure

Under normal atmospheric pressure, water boils at 100°C (212°F). To reach the more lethal temperature of 121°C, the pressure inside the autoclave chamber must be increased.

The pressure itself (typically 15 psi or 103 kPa above atmospheric) does not kill the microbes. Its sole purpose is to raise the boiling point of water, making it possible to create the saturated steam needed for effective sterilization at 121°C.

Time as the Final Ingredient

The sterilization cycle time ensures two things. First, it allows time for the steam to fully penetrate complex or densely packed loads. Second, it guarantees that every part of the load is held at the target temperature of 121°C for long enough to achieve a complete spore kill.

Understanding the Trade-offs

While 121°C is the standard, it's important to understand why it was chosen over other temperatures. It represents a critical balance between lethality and practicality.

Damage to Sensitive Materials

Higher temperatures and pressures could sterilize faster, but they also increase the risk of damage. Many plastics, laboratory reagents, and delicate instruments cannot withstand temperatures much higher than 121°C. This temperature is a sweet spot that sterilizes effectively while preserving the integrity of most common lab and medical equipment.

Energy and Equipment Costs

Operating at significantly higher temperatures requires more robust, and therefore more expensive, pressure vessels. It also consumes more energy. The 121°C standard is an energy-efficient and cost-effective method for achieving a reliable sterile state.

The "Flash" Sterilization Exception

In certain urgent medical situations, a "flash" cycle may be used, typically at 134°C for a much shorter duration (3-4 minutes) for unwrapped, simple instruments. This highlights the time-temperature relationship but is not the standard for general-purpose loads due to its limited application and higher risk of material damage.

Making the Right Choice for Your Goal

Understanding the principle behind the 121°C standard empowers you to use your autoclave correctly and confidently.

- If your primary focus is routine sterilization of glass, media, and durable goods: The standard 121°C cycle for 15-30 minutes is the validated, gold-standard method that ensures the highest level of sterility.

- If you are working with heat-sensitive plastics or liquids: You must verify the material's tolerance for the 121°C cycle and consider shortening the time or using an alternative, lower-temperature sterilization method if necessary.

- If you are validating your sterilization process: Always use a biological indicator containing Geobacillus stearothermophilus spores to confirm your autoclave is reaching the lethal conditions required.

Trusting the 121°C standard is trusting a century of validated science designed to ensure absolute sterility.

Summary Table:

| Factor | Role in Sterilization | Key Insight |

|---|---|---|

| Temperature (121°C) | Destroys heat-resistant bacterial endospores | The lethal threshold for the toughest microbes like Geobacillus stearothermophilus |

| Saturated Steam | Transfers heat efficiently via condensation | More effective than dry heat; denatures proteins and melts lipids |

| Pressure (15 psi) | Raises water's boiling point to reach 121°C | Enables the creation of saturated steam, but pressure itself doesn't kill microbes |

| Time (15-30 min) | Ensures steam penetration and complete spore kill | Balances lethality with material safety and energy efficiency |

Ensure Your Lab's Sterilization is Uncompromising

Trusting the 121°C standard means trusting a process designed for absolute safety. At KINTEK, we specialize in providing reliable autoclaves and lab equipment that meet these critical sterilization requirements. Whether you're processing glassware, media, or durable goods, our solutions are engineered for precision and durability.

Contact us today to find the perfect autoclave for your laboratory needs and achieve peace of mind with every cycle. Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- How do you sterilise without an autoclave? Effective methods for heat-sensitive materials

- Why is an autoclave used for the Hydrogen Disbonding Test? Ensuring 5Cr-0.5Mo Steel Cladding Integrity

- What are the settings of autoclave in microbiology? Achieve Guaranteed Sterility for Your Lab

- What role do laboratory autoclaves play in evaluating nuclear stainless steel? Ensure Safety with Realistic Simulation

- Why must Ni-Cr alloy and carbon-coated samples be treated in a pressure steam autoclave? Ensure Data Integrity

- Can an autoclave reach temps as high as 121 degrees Celsius? The Definitive Guide to Steam Sterilization

- What is the function of a high-pressure static autoclave in biomass HTL? Optimize Your Biomass Conversion Research

- What is the daily maintenance of autoclave? Essential Steps for Safe and Reliable Sterilization