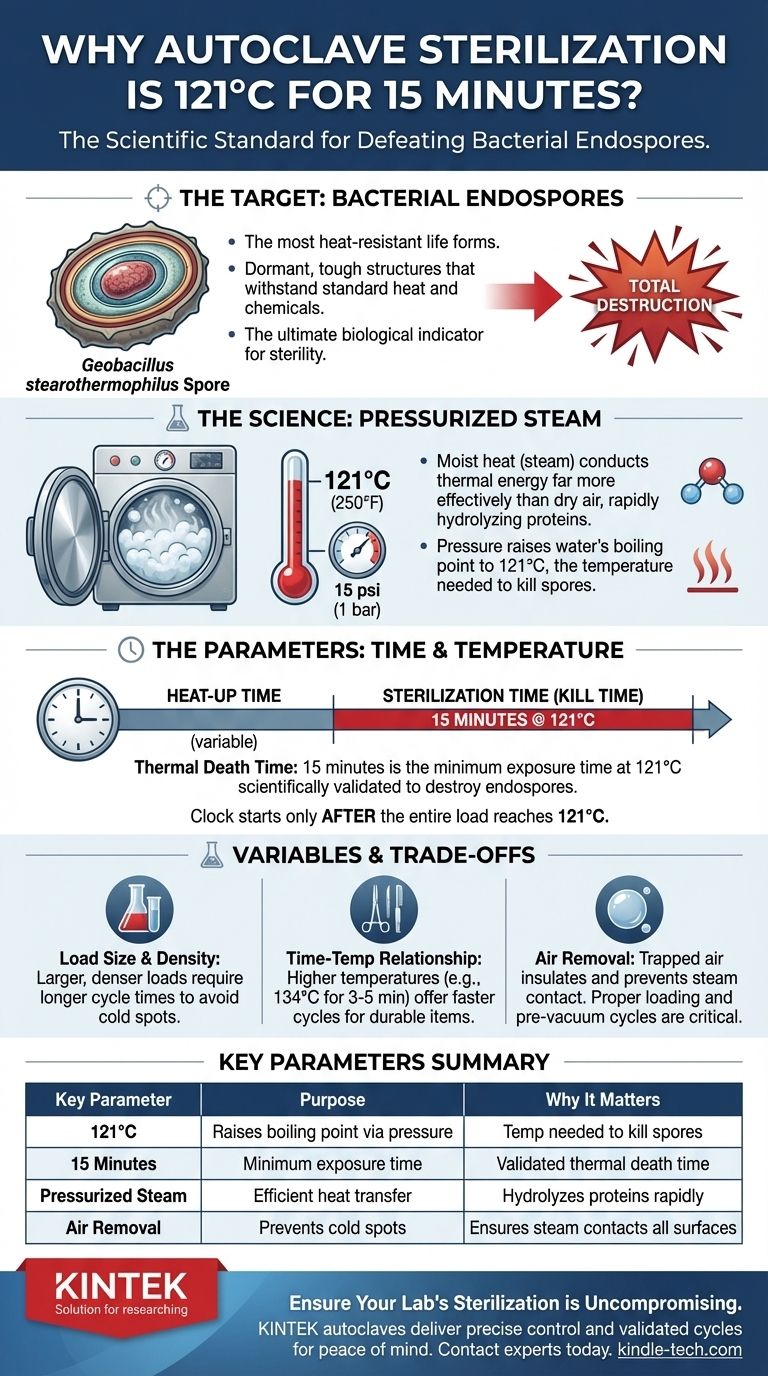

In short, the standard autoclave parameters of 121°C for 15 minutes are the scientifically established minimum conditions required to kill the most heat-resistant life forms on Earth: bacterial endospores. This specific combination of temperature, time, and pressurized steam ensures that all microbial life is destroyed, achieving true sterility. The entire process is designed around defeating this toughest-possible target.

The core principle is not just about heat, but about using pressurized steam to achieve a temperature that efficiently destroys the robust cellular structures of bacterial spores. The pressure itself doesn't kill microbes; it's the tool that allows water to reach 121°C, while the steam transfers this lethal heat far more effectively than dry air.

The Science of Steam Sterilization

To understand the 121°C / 15-minute standard, we first need to understand why an autoclave works at all. It's a precise balance of steam, pressure, and time.

Why Steam is More Effective Than Dry Heat

Sterilizing something in a 121°C oven (dry heat) is far less effective than in a 121°C autoclave (moist heat). This is because moist heat is a much better conductor of thermal energy.

The moisture in the steam rapidly transfers heat into microorganisms, breaking down their essential proteins and enzymes through a process called hydrolysis. This process is significantly faster and occurs at lower temperatures than the oxidation that occurs during dry heat sterilization.

The Critical Role of Pressure

At normal atmospheric pressure, water boils at 100°C. This temperature is sufficient to kill many bacteria, but it is not hot enough to reliably destroy hardy bacterial endospores.

To overcome this, an autoclave operates as a pressure chamber. By increasing the pressure inside the vessel to approximately 15 pounds per square inch (psi) or 1 bar above atmospheric pressure, the boiling point of water is raised to 121°C. Pressure is simply the mechanism used to achieve the required sterilizing temperature.

The Target: Defeating Bacterial Endospores

The entire framework of autoclaving is built around a single goal: ensuring the destruction of bacterial endospores.

The Gold Standard for Sterility

Certain bacteria, like Geobacillus stearothermophilus, produce endospores as a survival mechanism in harsh conditions. These spores are dormant, incredibly tough structures that can withstand heat, radiation, and chemicals that would kill active bacteria.

Because these spores are the most difficult form of life to kill with heat, they serve as the ultimate biological indicator. If your sterilization cycle can kill them, you can be confident it has killed everything else.

Thermal Death Time Explained

The 121°C for 15 minutes standard is derived from the thermal death time for these spores. Scientific studies determined that exposing spores to saturated steam at 121°C for a minimum of 15 minutes provides a sufficient "lethality rate" to ensure sterilization.

Crucially, this 15-minute clock only starts after the entire load has reached the target temperature of 121°C. This is a common point of misunderstanding; the total cycle time is always longer.

Understanding the Trade-offs and Variables

While 121°C for 15 minutes is the baseline, it is not the only valid cycle. The parameters must be adjusted based on the materials being sterilized and the nature of the load.

The Impact of Load Size and Density

A small load of glassware will heat up much faster than a large, dense bag of biological waste or a tightly packed surgical kit.

A larger or denser load requires a longer overall cycle time to ensure that steam penetrates to the very center and holds it at 121°C for the full 15 minutes. Failure to account for load density can lead to "cold spots" and incomplete sterilization.

The Time-Temperature Relationship

There is an inverse relationship between temperature and time. Higher temperatures can achieve sterilization in a shorter period.

For example, another common cycle is 134°C for 3-5 minutes. This is often used for sterilizing surgical instruments in hospitals because the faster cycle time is more efficient. However, this higher temperature can damage more sensitive materials like some plastics or laboratory media.

The Critical Need for Air Removal

Steam must be able to directly contact every surface to be sterilized. Trapped air is the enemy of effective autoclaving because it creates insulating pockets that prevent the steam from reaching the necessary temperature.

This is why proper loading is critical—items should not be packed too tightly. Advanced autoclaves also run pre-vacuum cycles to actively remove air from the chamber before injecting steam.

Making the Right Choice for Your Goal

Understanding these core principles allows you to ensure your sterilization process is both safe and effective.

- If your primary focus is routine lab work (e.g., media, glassware): The 121°C, 15-minute cycle is the validated, gold-standard protocol.

- If you are sterilizing large, dense, or porous loads: Increase the total cycle time to ensure the core of the load reaches temperature for the required duration.

- If speed is your highest priority (e.g., clinical instruments): A higher temperature cycle, such as 134°C for a shorter time, may be appropriate if the materials can withstand it.

- If you are sterilizing critical items (e.g., medical implants): Always validate the cycle's effectiveness using biological indicators (spore strips) to confirm that the conditions for killing spores were met.

Ultimately, mastering autoclaving means recognizing it as a scientific process, not just a recipe to be followed blindly.

Summary Table:

| Key Parameter | Purpose | Why It Matters |

|---|---|---|

| 121°C | Raises water's boiling point via pressure | Temperature needed to destroy bacterial endospores, the toughest microbial life form |

| 15 Minutes | Minimum exposure time at 121°C | Scientifically validated thermal death time for spores like Geobacillus stearothermophilus |

| Pressurized Steam | Ensures efficient heat transfer via moist heat | Steam conducts heat better than dry air, rapidly hydrolyzing proteins and enzymes |

| Air Removal | Prevents insulating cold spots | Critical for steam to contact all surfaces; autoclaves use pre-vacuum cycles for this |

Ensure Your Lab's Sterilization is Uncompromising

Choosing the right autoclave and understanding its parameters is critical for effective sterilization. Whether you're processing glassware, media, or sensitive instruments, KINTEK's range of laboratory autoclaves is designed to deliver precise temperature control, reliable steam penetration, and validated cycles for complete peace of mind.

Let KINTEK support your laboratory's sterilization needs with equipment that guarantees safety and efficiency. Contact our experts today to find the perfect autoclave solution for your specific applications.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- Which instrument Cannot be autoclaved? Protect Your Lab Equipment from Sterilization Damage

- Why are high-pressure autoclaves required for Zirconium alloy testing? Essential for Nuclear Environment Validation

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing

- What is the most commonly used autoclave? Discover the Industry Standard for Sterilization

- What is the function of a laboratory autoclave in dilute acid pretreatment? Unlock Biomass Energy Efficiently

- How long does it take to use an autoclave? A Complete Guide to Cycle Times

- How long does it take for the autoclave to complete its cycle? From 30 Minutes to Over an Hour

- What are the functions of an autoclave and alumina liner in LBE experiments? Protect Your Research & Data Integrity.