In short, 121°C is the gold standard for autoclaving because it is the minimum temperature required to reliably destroy the most heat-resistant lifeforms on Earth: bacterial spores. This temperature is achieved by using pressurized steam, which acts as a highly efficient vehicle for transferring lethal heat to every surface, ensuring complete sterilization within a practical timeframe of 15 to 20 minutes.

The use of 121°C is not arbitrary; it is a scientifically determined benchmark that balances lethality against microbes with the practical constraints of time and material integrity. It represents the point where saturated steam, under pressure, guarantees sterility against the toughest biological challenges.

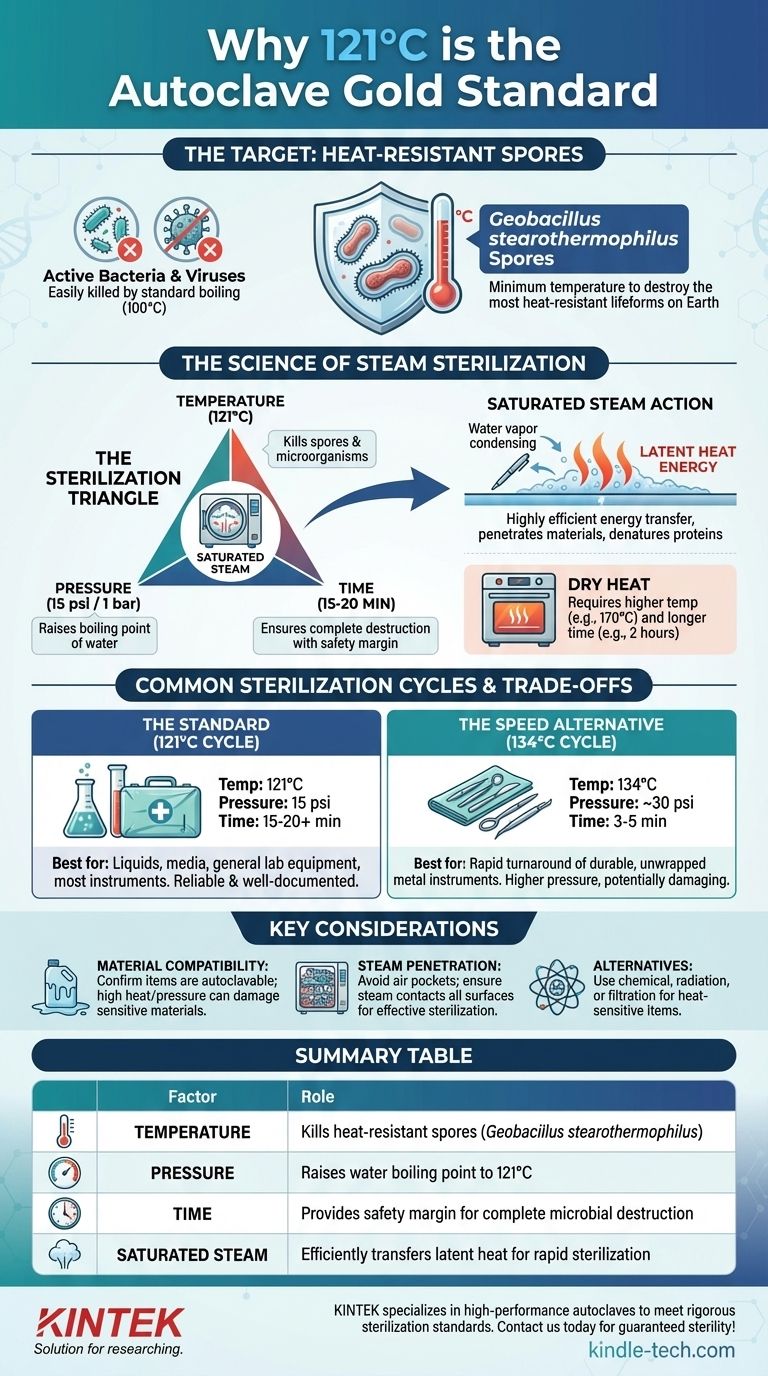

The Science of Steam Sterilization

To understand the significance of 121°C, you must first understand that standard boiling is insufficient. The real goal of sterilization is to achieve a complete kill of all microorganisms, including the hardiest forms.

Beyond Boiling Water

Simply boiling instruments in water at 100°C (212°F) will kill most active bacteria and viruses. However, it is not hot enough to reliably destroy bacterial spores.

These spores are dormant, highly protected structures that some bacteria form to survive extreme environmental stress, including heat.

The Target: Heat-Resistant Spores

The entire process of steam sterilization is validated against its toughest opponent: the spores of a thermophilic (heat-loving) bacterium, typically Geobacillus stearothermophilus.

This organism is harmless to humans but is exceptionally resistant to heat. The 121°C temperature is specifically chosen because it provides a reliable kill condition for these spores, ensuring that anything less resistant is also eliminated.

The Critical Role of Pressure

At normal atmospheric pressure, water cannot exceed its boiling point of 100°C. To reach 121°C, an autoclave increases the pressure inside its chamber.

By increasing the pressure to approximately 15 pounds per square inch (psi) or 1 bar above atmospheric pressure, the boiling point of water is raised to 121°C.

Saturated Steam: The Real Killing Agent

The true agent of destruction in an autoclave is not just the heat, but saturated steam. As this high-temperature steam makes contact with the cooler items inside the autoclave, it immediately condenses back into water.

This phase change releases a massive amount of energy known as the "latent heat of vaporization." This energy transfer is far more efficient and rapid than dry heat, allowing it to quickly penetrate materials and denature the essential proteins and enzymes of microorganisms, killing them.

The Sterilization Triangle: Temperature, Time, and Pressure

Sterilization is not just about temperature; it's a function of temperature, the time exposed to that temperature, and the pressure required to achieve it.

The 121°C Standard

The most common and widely validated cycle is 121°C at 15 psi for a minimum of 15 minutes. This is the standard for sterilizing laboratory media, liquids, glass, and most common surgical instruments. The 15-minute duration provides a crucial margin of safety.

The Alternative: 134°C for Speed

As noted in sterilization guidelines, higher temperatures can also be used. A common alternative cycle is 134°C for 3-5 minutes.

This "flash sterilization" cycle is much faster but generates higher pressure and can be more damaging to sensitive items. It is often reserved for unwrapped, solid metal instruments that need to be used again quickly.

Understanding the Trade-offs

Choosing a sterilization cycle requires balancing effectiveness with the potential for damaging the items being sterilized.

Risk of Material Damage

The combination of high temperature, pressure, and moisture can degrade or destroy many materials. Certain plastics may melt, paper can become brittle, and complex electronics will be destroyed. It is critical to confirm that an item is "autoclavable" before processing.

The Importance of Steam Penetration

Effective sterilization depends entirely on steam contacting every single surface. If an autoclave is packed too densely or items are wrapped improperly, air pockets can form.

Air is a poor conductor of heat and will prevent the steam from reaching surfaces, leaving them unsterilized even if the chamber reaches 121°C.

Contrast with Dry Heat

To appreciate the efficiency of steam, consider dry heat sterilization. Without the moisture from steam, dry heat requires much higher temperatures (e.g., 170°C / 340°F) and far longer exposure times (e.g., 2 hours) to achieve the same level of sterility. This highlights the superior energy transfer of saturated steam.

Making the Right Choice for Your Goal

The correct autoclave cycle depends directly on your materials and your need for speed.

- If your primary focus is safe sterilization of liquids, media, and general lab equipment: The classic 121°C for 15-20 minutes is the most reliable and well-documented choice.

- If your primary focus is rapid turnaround of durable, unwrapped metal instruments: A 134°C cycle for 3-5 minutes is a highly effective and efficient alternative, provided the instruments can tolerate it.

- If your primary focus is sterilizing heat-sensitive plastics or electronics: The autoclave is the wrong tool, and you must use other methods like chemical sterilization, radiation, or filtration.

Understanding that 121°C is a deliberate, science-backed choice empowers you to use this critical tool effectively and ensure the integrity of your work.

Summary Table:

| Key Factor | Role in Sterilization |

|---|---|

| Temperature (121°C) | Minimum required to kill the most heat-resistant bacterial spores (e.g., Geobacillus stearothermophilus). |

| Pressure (15 psi) | Raises water's boiling point to achieve 121°C, enabling saturated steam formation. |

| Time (15-20 min) | Provides a safety margin to ensure complete microbial destruction. |

| Saturated Steam | Condenses on surfaces, transferring latent heat efficiently for rapid sterilization. |

Ensure your lab's sterilization is both effective and efficient. KINTEK specializes in high-performance autoclaves and lab equipment designed to meet rigorous sterilization standards. Whether you need reliable 121°C cycles for media and instruments or rapid 134°C cycles for durable tools, our solutions are tailored to your laboratory's unique needs. Contact us today to find the perfect autoclave for your workflow and achieve guaranteed sterility!

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- Why is the standard autoclave temperature set to 121? The Science of Effective Sterilization

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What is the life expectancy of an autoclave machine? Maximize Your Investment with Proper Care