Introduction to Distillation Technologies

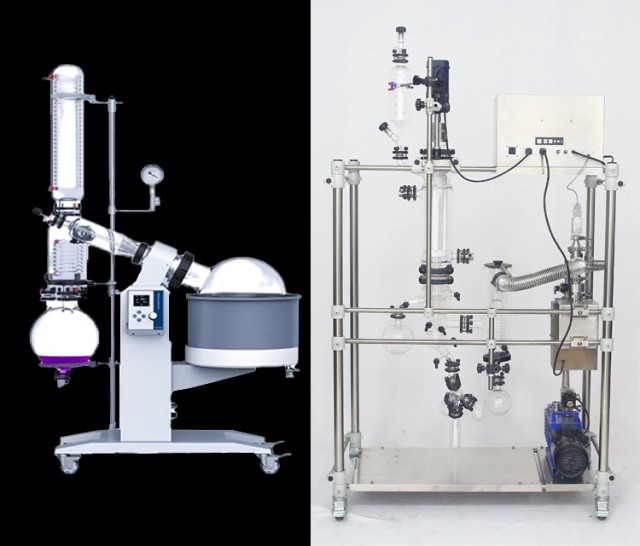

Distillation is a separation technique used to purify liquids through heat application and vaporization. It is a crucial process in various industries such as the chemical, pharmaceutical, and food industries. There are various distillation technologies available, each with its unique advantages and disadvantages. The most commonly used distillation technology is the Rotovap, which is a rotary evaporator. It uses a vacuum and heat to extract the desired substance from the mixture, making it a popular choice for laboratory applications. Other distillation technologies include fractional distillation, short-path distillation, and wiped film distillation, each with its distinctive features.

Table of Contents

- Introduction to Distillation Technologies

- How a Rotovap Works

- Advantages of Rotovap Distillation

- Disadvantages of Rotovap Distillation

- Not Suitable for Distilling Large Volumes of Samples

- Difficult to Control Temperature of Distillation Process

- More Expensive Than Other Distillation Techniques

- Structure is Difficult to Clean and Sanitize

- Not Suitable for Foaming Samples

- Distilled and Concentrated Substances Will Be Spread on Wall of Bottles

- Other Distillation Technologies Overview

- Comparison of Rotovap and Other Distillation Technologies

- Conclusion

How a Rotovap Works

Rotary evaporators, also known as rotovaps, are widely used in laboratories to distill solvents and purify them. The process of using a rotovap involves rotating the flask containing the solvent while applying heat, which increases the surface area of the solvent exposed to the vacuum. The vacuum lowers the boiling point of the solvent, making it easier to evaporate. The condenser then cools the vapor, causing it to condense into a separate flask. Here is a step-by-step guide on how a rotovap works:

Step 1: Load the Sample

The sample is loaded into the evaporation flask, which is then connected to the rotary evaporator.

Step 2: Apply Vacuum

The vacuum pump is turned on, creating a low-pressure environment in the system. The vacuum lowers the boiling point of the solvent, allowing it to evaporate at lower temperatures.

Step 3: Rotate the Flask

The flask containing the sample is rotated using the rotary motor. The rotation helps to spread the sample across the surface of the flask, increasing exposure to the vacuum and promoting even evaporation.

Step 4: Heat the Flask

The flask is heated using a water bath or heating mantle. As the solvent evaporates, it condenses on the cooler surface of the condenser.

Step 5: Condense the Vapor

The vapor travels through the condenser, which cools it down and causes it to condense into a separate flask.

Step 6: Collect the Distillate

The distillate, which contains the purified solvent, is collected in the receiving flask. The remaining sample residue is left in the original flask.

Rotary evaporators are more versatile and can handle a wider range of solvents compared to other distillation methods. The main advantage of using rotovaps over other distillation technologies is that it allows for faster and more efficient solvent separation with higher purity levels. The process of using a rotovap is simple and straightforward, making it a popular choice for laboratories around the world.

Advantages of Rotovap Distillation

Rotovap distillation is a highly efficient and effective method of distillation that offers several advantages over other distillation technologies. In this section, we will discuss the advantages of rotovap distillation in detail.

Lower Boiling Temperatures

Rotovap distillation utilizes a vacuum system to reduce the pressure of the system, which means that the separation of solvents and other compounds can be achieved at lower temperatures than usual. This reduces the risk of damage to the sample and prolongs the lifespan of the glass apparatus, as they are exposed to lower temperatures.

Faster Evaporation of Solvent

Rotovap distillation involves two main forces: the centripetal force and friction. These forces act between the evaporation bottle or round-bottomed flask and the liquid mixture, allowing the mixture to form a film on the inner surface of the flask, creating a larger surface area for heating. The rotation of the flask at a constant speed also contributes to an increased surface area, which speeds up the distillation process.

Fewer Operations

Rotovap distillation consists of a built-in lifting and falling motor that enables the automatic raising of the rotary bottle to a position just above the water bath for the rotation process. This means that a technician is less involved in the holding of the apparatus, which makes work easier for them. The motor is electrically powered, and this means that the apparatus can be used as long as there is power. This makes it an efficient and reliable apparatus for most chemistry labs.

Suppresses Bumping

Due to the forces that contribute to the evaporation process (centripetal force and friction), bumping is often suppressed in rotovap distillation. This allows for quick and gentle evaporation of mixtures, and therefore allows even the inexperienced users to utilize these apparatus. The solvent remaining after the rotary evaporation can further be removed through a deeper vacuum or a tightly sealed vacuum system at ambient or relatively higher temperatures.

Environmentally Friendly

Another advantage of rotovap distillation is that it requires less solvent and energy, making it more environmentally friendly compared to other distillation technologies. This is because rotovap distillation utilizes a vacuum system to reduce the pressure of the system, which reduces the boiling temperature of the solvent and requires less energy to remove the solvent.

In conclusion, rotovap distillation offers several advantages over other distillation technologies. Its precision, speed, efficiency, and environmentally friendly nature make it a popular choice in laboratories for a wide range of applications.

Disadvantages of Rotovap Distillation

Rotovap distillation is a popular method of distillation in laboratories, but it does have some notable disadvantages. Here are some of the drawbacks of using rotovap distillation:

Not Suitable for Distilling Large Volumes of Samples

One of the main disadvantages of rotovap distillation is that it is not suitable for distilling large volumes of samples. This is because rotovap distillation is a batch process that requires a lot of time and effort to set up and run. It is not very efficient at distilling large volumes of samples.

Difficult to Control Temperature of Distillation Process

Another disadvantage of rotovap distillation is that it can be difficult to control the temperature of the distillation process. This is because the temperature of the rotovap flask can fluctuate rapidly, which can lead to incomplete or inconsistent distillation of the sample.

More Expensive Than Other Distillation Techniques

Rotovap distillation can be more expensive than other distillation techniques, as it requires specialized equipment and consumables. The cost of purchasing and maintaining a rotovap can be prohibitive for some laboratories.

Structure is Difficult to Clean and Sanitize

The structure of rotary evaporators can be difficult to clean and sanitize. This can lead to cross-contamination when bumping happens. The difficulty of cleaning and sanitizing the structure can be a major drawback for laboratories that prioritize cleanliness and sterility.

Not Suitable for Foaming Samples

Rotovap distillation is not suitable for foaming samples, or should be used with a defoamer or specialized condenser. The presence of foam can cause the sample to bump, leading to incomplete distillation and loss of sample.

Distilled and Concentrated Substances Will Be Spread on Wall of Bottles

Distilled and concentrated substances from rotovap distillation will be spread on the wall of bottles. This can make it difficult to collect all of the sample and can lead to loss of the sample.

Despite these drawbacks, rotovap distillation remains a popular and effective method of distillation for many laboratory applications. By understanding the advantages and disadvantages of different distillation techniques, researchers can choose the most appropriate method for their specific needs.

Other Distillation Technologies Overview

In addition to rotovap distillation, there are several other distillation technologies commonly used in laboratory settings. Each method has its own unique advantages and disadvantages, and the choice of method depends on the properties of the liquids being distilled.

Simple Distillation

Simple distillation is the most basic form of distillation and is used for separating liquids with a large difference in boiling points. In simple distillation, the liquid is heated to its boiling point, and the resulting vapor is condensed and collected in a separate container. This method is effective for separating liquids with a boiling point difference of at least 25-30°C.

Fractional Distillation

Fractional distillation is similar to simple distillation but utilizes a fractionating column to improve separation. The fractionating column contains a series of plates or packing material that provides a larger surface area for vapor condensation and re-evaporation. This method is effective for separating liquids with a boiling point difference of less than 25-30°C.

Steam Distillation

Steam distillation is used for separating heat-sensitive compounds and involves passing steam through the mixture to vaporize the desired compound. The steam and vapor mixture is then condensed and collected in a separate container. This method is commonly used for extracting essential oils from plants.

Vacuum Distillation

Vacuum distillation is used for distilling liquids with high boiling points. In vacuum distillation, the pressure is lowered, which lowers the boiling point of the liquid. This method is commonly used for distilling petroleum products.

Short Path Distillation

Short path distillation is a type of fractional distillation that is used for separating liquids with a high boiling point difference. In short path distillation, the mixture is heated and allowed to evaporate, and the resulting vapor is condensed and collected in a separate container. This method is commonly used in the production of high-purity CBD and THC products.

Overall, there are many different types of distillation technologies available, each with its own unique advantages and disadvantages. The choice of method depends on the properties of the liquids being distilled and the desired outcome of the distillation process.

Comparison of Rotovap and Other Distillation Technologies

Introduction

Distillation is an important laboratory technique used for separating and purifying different chemical compounds. There are various types of distillation methods including rotovap distillation, short path distillation, and fractional distillation. This article will compare rotovap distillation with other distillation technologies.

Rotovap Distillation vs. Short Path Distillation

Short path distillation is another popular method that is suitable for purifying heat-sensitive compounds. Compared to rotovap distillation, short path distillation requires a vacuum pump to operate. The short path distillation kit separates the components based on their boiling points. Rotovap distillation is more efficient, faster, and produces high-quality extracts, making it the preferred choice for the extraction of volatile compounds.

Rotovap Distillation vs. Fractional Distillation

Fractional distillation is a technique used to separate two or more liquids with different boiling points. This method is useful for separating complex mixtures and is commonly used in the petroleum industry. Rotovap distillation is better suited for the extraction of essential oils and other volatile compounds. Fractional distillation is slower and less efficient than rotovap distillation.

Conclusion

In conclusion, the choice of distillation technology depends on the specific needs of the laboratory. The Rotovap is a popular choice due to its ease of use, high efficiency, and low cost. However, other technologies such as short-path distillation and fractional distillation may be more suitable for certain applications. It is important to consider factors such as the volume of the sample, the desired purity, and the types of compounds being separated when choosing a distillation method. Ultimately, a thorough understanding of the benefits and limitations of each technology is essential to make an informed decision.

CONTACT US FOR A FREE CONSULTATION

KINTEK LAB SOLUTION's products and services have been recognized by customers around the world. Our staff will be happy to assist with any inquiry you might have. Contact us for a free consultation and talk to a product specialist to find the most suitable solution for your application needs!