Usage of Thermostatic Water Baths

Setting Up and Operating the Water Bath

Setting up a constant temperature water bath involves several key steps to ensure optimal performance and safety. First and foremost, the water bath should be securely placed on a stable, fixed platform to prevent any accidental tipping or movement during operation. This stable foundation is crucial for maintaining the accuracy of temperature regulation.

Once the water bath is properly positioned, the next step is to turn on the power. This initializes the heating and temperature control systems, allowing you to proceed with the temperature adjustment. The temperature should be set according to the specific requirements of the experiment or process. Modern water baths often come with digital interfaces that allow for precise temperature settings, ensuring that the desired temperature is achieved and maintained.

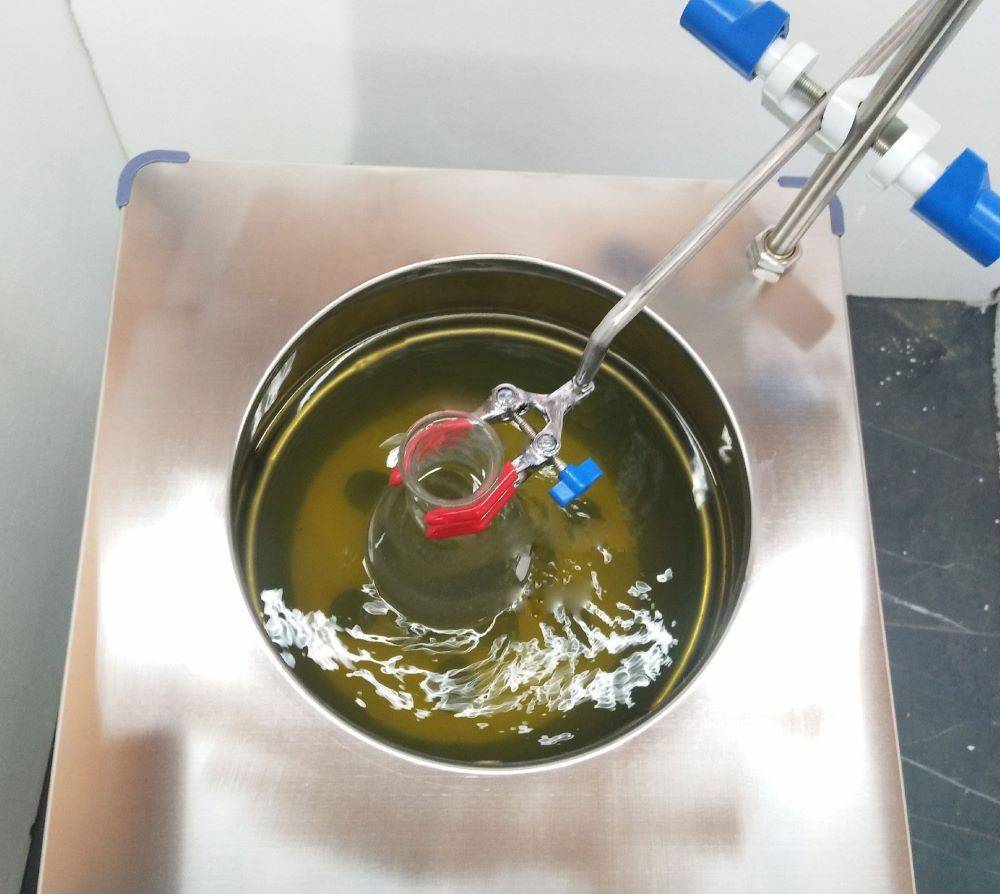

After setting the desired temperature, the container with the items to be thermostated should be carefully placed into the water bath. It is important to ensure that the items are fully submerged and that there is adequate water in the bath to cover them. This ensures uniform heating and effective thermostating. The container should be placed in such a way that it does not obstruct the water flow or the temperature sensors, which could affect the accuracy of the temperature control.

In summary, setting up and operating a constant temperature water bath requires careful attention to placement, precise temperature adjustment, and proper submersion of the items to be thermostated. These steps ensure that the water bath operates efficiently and safely, providing reliable temperature control for various applications.

Ensuring Effective Thermostatting

To ensure the optimal performance of a thermostatic water bath, several critical steps must be followed. First and foremost, sealing the contact parts with a suitable material like cardboard is essential. This prevents heat loss and ensures that the temperature remains consistent throughout the bath. Additionally, it is crucial to position the items to be thermostated below the water bath surface. This placement ensures that the items are fully submerged and can achieve the desired temperature uniformly.

Furthermore, maintaining a stable water level within the bath is vital. Fluctuations in the water level can lead to inconsistent heating, thereby compromising the thermostatting process. Regularly checking and adjusting the water level can prevent such issues.

Another key aspect is insulating the bath to minimize heat loss. Using insulation materials around the bath can help retain heat, thereby reducing energy consumption and ensuring that the set temperature is maintained efficiently.

Lastly, regular monitoring of the temperature is necessary. Employing high-resolution temperature measurement equipment with a resolution of 0.1℃ or less can provide accurate readings. This ensures that any deviations from the set temperature are promptly identified and corrected, thereby maintaining the integrity of the thermostatting process.

Post-Use Procedures

After completing your experiment or process, it's crucial to follow a systematic shutdown procedure to ensure the longevity and accuracy of your thermostatic water bath. Begin by carefully removing the thermostat from the water bath. This step is essential as it prevents any accidental settings changes and ensures the thermostat is not left in a potentially damaging environment.

Next, turn off the power supply. This not only saves energy but also reduces wear and tear on the equipment. Ensure that all power connections are safely disconnected to avoid any electrical hazards.

Once the power is off, proceed to empty the water from the bath. This prevents the growth of bacteria and mold, which can contaminate future experiments. Use a clean, dry cloth to wipe down the interior and exterior surfaces of the water bath, removing any residual water or debris.

Finally, document the use of the instrument. Record the date, time, duration of use, and any observations or issues encountered during operation. This log can be invaluable for troubleshooting and maintenance purposes, helping to identify patterns or recurring problems.

By adhering to these post-use procedures, you not only extend the life of your thermostatic water bath but also ensure that it remains in optimal condition for future experiments.

Precautions for Water Baths

Safety and Maintenance

Maintaining the cleanliness of both the interior and exterior of the water bath is crucial for its longevity and efficient operation. Regular tidying not only prevents the accumulation of debris that could interfere with the bath's performance but also ensures a safer working environment.

Moreover, electrical safety is paramount. The water bath must be effectively grounded to prevent any risk of electric shock, especially since it operates with water, a known conductor of electricity. It is imperative to avoid using the water bath without water, as this can lead to overheating and potential damage to the electric heating element and other critical components.

For optimal safety and performance, consider the following maintenance practices:

-

Regular Cleaning: After each use, clean the interior and exterior surfaces to remove any residue or debris. This helps in preventing contamination and ensures that the bath operates efficiently.

-

Electrical Checks: Periodically inspect the grounding of the water bath to ensure it remains effective. Additionally, monitor for any signs of electrical wear or damage that could compromise safety.

-

Water Presence: Always ensure that the water bath contains water before operating it. Running the bath without water can cause significant damage to the electric heating element and other internal components.

By adhering to these maintenance guidelines, you can ensure that your thermostatic water bath remains in optimal condition, providing reliable and safe performance for extended periods.

Handling Equipment Issues

When troubleshooting a thermostatic water bath, one of the first steps is to check the indicator light. If the indicator light fails to illuminate, it is crucial to inspect both the fuse and the bulb. These components are often the first to fail in the event of a power-related issue.

To resolve this, replace any damaged fuses or bulbs immediately. Ensure that the replacement components are of the same specifications to avoid compatibility issues. Additionally, it is essential to verify that the thermostat controller is functioning correctly. This involves checking the connections and ensuring that the controller responds accurately to temperature adjustments.

| Component to Check | Action to Take |

|---|---|

| Fuse | Replace if damaged |

| Bulb | Replace if burned out |

| Thermostat Controller | Verify functionality |

By systematically addressing these components, you can quickly restore the water bath to operational status.

Common Failures and Troubleshooting

Non-Heating Issues

If your thermostatic water bath fails to heat, it's crucial to diagnose the problem systematically. Begin by examining the temperature controller output. Ensure that the controller is providing the correct signal to the heating element. If the controller appears to be functioning correctly, the next step is to check the voltage input to the heating tube. A lack of voltage or an incorrect voltage level can prevent the heating tube from operating effectively.

In cases where the temperature controller and voltage input are functioning as expected, the issue may lie with the heating tube itself. Faulty heating elements are a common cause of non-heating issues. If you identify a problem with the heating tube, it should be replaced promptly. Additionally, inspect other components in the heating circuit, such as relays and connections, to rule out any secondary faults that could be impeding the heating process.

To summarize, troubleshooting non-heating issues involves a step-by-step approach:

- Check the temperature controller output.

- Verify the voltage input to the heating tube.

- Replace faulty heating tubes and other defective components.

By following these steps, you can efficiently diagnose and resolve non-heating problems in your thermostatic water bath.

Temperature Sensor Problems

When dealing with temperature sensor issues in thermostatic water baths, it's crucial to identify and rectify problems promptly to maintain the accuracy and reliability of the equipment. One of the most common indicators of a faulty temperature sensor is the display of error codes such as "LLL" or "999." These codes typically signal a break or short-circuit within the sensor, rendering it incapable of accurately measuring and transmitting temperature data.

Symptoms and Solutions

| Error Code | Possible Cause | Recommended Action |

|---|---|---|

| LLL | Sensor break or disconnection | Replace the temperature sensor immediately. |

| 999 | Short-circuit in the sensor | Replace the temperature sensor immediately. |

Steps for Replacement

- Identify the Issue: First, confirm the error code on the display. If it shows "LLL" or "999," the sensor is likely faulty.

- Power Off: Ensure the water bath is powered off to avoid any electrical hazards during the replacement process.

- Remove the Sensor: Carefully detach the old temperature sensor from its mounting point. Follow the manufacturer's instructions for removal.

- Install New Sensor: Attach the new temperature sensor securely, ensuring it is properly connected.

- Power On and Test: Turn the water bath back on and monitor the temperature display. Verify that the new sensor is functioning correctly without any error codes.

By following these steps, you can effectively troubleshoot and resolve temperature sensor problems, ensuring your thermostatic water bath operates efficiently and accurately.

Temperature Control Failures

When dealing with temperature control failures in thermostatic water baths, it's crucial to diagnose the issue accurately to restore functionality. One common cause is faulty relays, which can disrupt the electrical circuit responsible for maintaining the desired temperature. These relays might fail due to wear and tear or electrical surges, necessitating immediate replacement.

Another potential issue is moisture ingress into the temperature sensor. Moisture can compromise the sensor's ability to accurately read and regulate temperature, leading to erratic performance. In such cases, the sensor must be dried thoroughly or replaced if moisture has caused irreversible damage.

| Issue | Cause | Solution |

|---|---|---|

| Faulty Relays | Wear and tear, electrical surges | Replace faulty relays |

| Moisture in Sensor | Ingress of water or humidity | Dry or replace the sensor |

Regular inspections and prompt replacements of faulty components are essential for maintaining the precision and reliability of thermostatic water baths.

Routine Maintenance of Water Baths

Cleaning Procedures

Immediately after using the thermostatic water bath, it is crucial to initiate the cleaning process without delay. Start by draining the water and carefully removing any debris that may have accumulated within the bath. This step is essential to prevent contamination and ensure the longevity of the equipment.

Next, focus on wiping down both the inner and outer surfaces of the water bath. Use appropriate cleaning agents that are safe for the materials of the bath to avoid any damage. Ensure that all surfaces are thoroughly cleaned to remove any residual substances that could affect future use.

For areas that are particularly prone to residue buildup, such as the heating elements and temperature sensors, a more detailed cleaning may be necessary. This can involve using specialized brushes or tools to reach all corners and crevices, ensuring that no part of the water bath is neglected.

Lastly, inspect the water bath for any signs of wear or damage that may have occurred during use. This proactive inspection can help identify issues early, allowing for timely repairs and preventing more significant problems down the line.

By following these detailed cleaning procedures, you can maintain the efficiency and accuracy of your thermostatic water bath, ensuring it continues to perform reliably in your laboratory or research setting.

Safety Measures

Ensuring the safety of your thermostatic water bath involves several critical steps to prevent electrical hazards and equipment damage. Firstly, grounding the water bath is paramount. A reliably grounded device protects against electric shocks and ensures that any stray electrical currents are safely directed away from the user and the equipment. This is particularly important when dealing with water, as water is an excellent conductor of electricity.

Another crucial safety measure is preventing water overflow into the control box. Water overflow can lead to short circuits, damaging the internal components of the water bath and potentially causing a fire hazard. To mitigate this risk, ensure that the water level in the bath is carefully monitored and maintained within safe limits. Additionally, consider installing a water level indicator or alarm system to alert you if the water level becomes too high.

| Safety Measure | Importance |

|---|---|

| Reliable Grounding | Prevents electric shocks and directs stray currents safely away. |

| Preventing Water Overflow | Avoids short circuits and fire hazards by keeping the control box dry. |

By adhering to these safety measures, you can significantly reduce the risk of accidents and prolong the lifespan of your thermostatic water bath.

Regular Maintenance Checks

Regular maintenance of thermostatic water baths is crucial to ensure their longevity and optimal performance. Monthly maintenance inspections should be conducted to identify and address any potential issues before they escalate. These inspections should encompass a thorough examination of all components, including the heating element, temperature sensor, and control mechanisms.

During these inspections, it is essential to record all maintenance activities in a detailed log. This documentation serves multiple purposes: it helps track the equipment's performance over time, provides a reference for future maintenance, and can be invaluable in troubleshooting any recurring issues. The log should include details such as the date of inspection, the condition of each component, any repairs or replacements made, and the overall functionality of the water bath post-maintenance.

Moreover, these monthly checks should also involve a visual inspection of the water bath's exterior and interior surfaces for any signs of wear or damage. Ensuring that the water bath is clean and free from debris not only enhances its aesthetic appeal but also prevents contamination that could affect the accuracy of temperature control.

In addition to routine inspections, it is advisable to perform functional tests to verify that all systems are operating correctly. This includes checking the temperature accuracy, ensuring the heating element responds promptly to adjustments, and confirming that the control panel displays accurate readings. By adhering to a consistent maintenance schedule and meticulously documenting each inspection, you can significantly prolong the lifespan of your thermostatic water bath and ensure it continues to function reliably in your laboratory or research setting.

Calibration of Water Baths

Environmental Conditions

When calibrating thermostatic water baths, it is crucial to create a stable and controlled environment. The ambient conditions must be meticulously managed to ensure accurate and reliable calibration results. Specifically, the ambient temperature should be maintained within a predefined range, typically between 15°C and 30°C, to prevent thermal fluctuations that could affect the calibration process. Similarly, humidity levels should be kept between 30% and 70% to avoid condensation and potential damage to the equipment.

In addition to temperature and humidity, other environmental factors must be considered. Strong vibrations can disrupt the calibration process by causing mechanical stress on the water bath and its components. Therefore, it is advisable to place the water bath on a stable, vibration-free surface. Moreover, exposure to corrosive gases can lead to the degradation of materials and components over time, compromising the accuracy and longevity of the water bath. To mitigate this risk, the calibration environment should be free from corrosive agents and well-ventilated.

By carefully controlling these environmental conditions, you can significantly enhance the precision and reliability of your thermostatic water bath calibration.

| Environmental Factor | Acceptable Range | Importance |

|---|---|---|

| Temperature | 15°C - 30°C | Prevents thermal fluctuations |

| Humidity | 30% - 70% | Avoids condensation and equipment damage |

| Vibrations | None | Prevents mechanical stress and disruption |

| Corrosive Gases | None | Prevents material degradation and component failure |

Temperature Measurement and Equipment

When calibrating thermostatic water baths, it is crucial to employ temperature measurement equipment that offers high precision. Specifically, instruments with a resolution of 0.1℃ or less are recommended to ensure accurate readings. This level of precision is essential for maintaining the integrity of the calibration process.

Key Considerations for Temperature Measurement Equipment

- Resolution: The equipment should have a resolution of 0.1℃ or better to capture minute temperature variations.

- Calibration Requirements: Ensure that the temperature measurement devices are calibrated according to industry standards and are traceable to recognized metrological institutions.

Importance of Calibration

Calibration of temperature measurement equipment is not just a regulatory requirement but also a practical necessity. It ensures that the readings provided by the equipment are reliable and consistent, which is critical for the accurate operation of thermostatic water baths. Regular calibration checks help in identifying any drift in the equipment's performance, allowing for timely adjustments or replacements.

By adhering to these guidelines, users can ensure that their thermostatic water baths are calibrated with the highest level of precision, thereby enhancing the overall reliability and effectiveness of the equipment.

Calibration Items and Procedures

Calibration of a thermostatic water bath involves several critical steps to ensure accurate temperature control. The primary focus is on temperature deviation, fluctuation, and uniformity. These aspects are crucial for maintaining the precision and reliability of the water bath in various scientific and industrial applications.

-

Temperature Deviation: This refers to the difference between the set temperature and the actual temperature within the water bath. To calibrate for deviation, use a high-precision thermometer with a resolution of 0.1℃ or less. Compare the readings from the thermometer with the set temperature on the water bath's control panel. Adjust the control settings as necessary to minimize this deviation.

-

Temperature Fluctuation: Fluctuation occurs when the temperature within the water bath varies over time, even when the set temperature remains constant. To assess fluctuation, monitor the temperature over a specified period, noting any variations. Use a data logger to record these readings and analyze the stability of the temperature. If significant fluctuations are observed, check for issues such as faulty sensors or inadequate insulation.

-

Temperature Uniformity: Uniformity ensures that the temperature is consistent throughout the water bath, not just at a single point. This is particularly important for applications requiring homogeneous heating. To check uniformity, place multiple temperature sensors at different positions within the bath and compare their readings. Any discrepancies indicate areas needing adjustment or repair.

| Calibration Aspect | Measurement Tool | Key Considerations |

|---|---|---|

| Temperature Deviation | High-precision thermometer | Resolution of 0.1℃ or less |

| Temperature Fluctuation | Data logger | Monitor over time, analyze stability |

| Temperature Uniformity | Multiple temperature sensors | Compare readings at different positions |

In addition to these technical aspects, it is essential to check the appearance and functionality of the water bath. Inspect for any physical damage, leaks, or signs of wear and tear. Ensure all components are functioning correctly, including the control panel, heating elements, and sensors. A thorough visual inspection can prevent potential issues that might affect calibration accuracy.

By systematically addressing these calibration items and procedures, you can ensure that your thermostatic water bath operates with the highest level of precision and reliability.

Related Products

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- 20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 30L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 5L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 10L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

Related Articles

- Choosing the Right Heating Method for Laboratory Experiments

- Electric Heating Systems(3): Understanding, Benefits, and Applications

- Comparing the Features of Laboratory Waterbaths: A Guide to Finding the Right Waterbath for Your Needs

- Basic Constant Temperature Heating Equipment in Laboratories

- Features and Precautions of Laboratory Water Bath Equipment