Table of Contents

- Introduction to XRF Spectrometer Modules

- Types of XRF Spectrometers: ED-XRF vs. WD-XRF

- Key Features and Operational Capabilities of XRF Spectrometer Modules

- Applications of XRF Spectrometer Modules Across Industries

- Advanced Analysis Techniques with XRF Spectrometer Modules

- Integration of XRF Spectrometer Modules with Automation and Robotics

- Choosing the Right XRF Spectrometer Module for Specific Needs

- Future Trends and Innovations in XRF Spectrometer Module Technology

Introduction to XRF Spectrometer Modules

"The world of scientific analysis has been revolutionized by the advent of XRF Spectrometer Modules. These versatile modules can be flexibly configured and integrated with robotic arms and automatic devices, forming efficient detection solutions tailored to different sample characteristics. In this comprehensive guide, we will explore the versatility and operational details of XRF Spectrometer Modules, including their integration with automation, types of XRF spectrometers, and their applications in various industries. Learn how these modules enhance real-time inspection and quality control in production lines. From Energy Dispersive XRF (ED-XRF) to Wavelength Dispersive XRF (WD-XRF), we will delve into the operational principles, resolution capabilities, and typical applications of these spectrometers. The guide will also discuss the non-destructive analysis feature of XRF Spectrometer Modules, which aids in preserving sample integrity while providing accurate elemental analysis. We will examine the diverse applications of XRF Spectrometer Modules in industries such as cement, metal ores, mineral ores, oil & gas, environmental, and geological sectors. Additionally, the guide will detail the analysis techniques used in XRF Spectrometer Modules, including the fundamental parameters method and the capability of analyzing light elements. The importance of these techniques in understanding sample mineralogy and enhancing analytical precision will be highlighted. Furthermore, we will explore how XRF Spectrometer Modules are effectively integrated with robotic arms and automatic devices to optimize factory production line layouts. Discussing the benefits of such integrations in terms of efficiency, accuracy, and reduced human intervention, we will guide you on selecting the appropriate XRF Spectrometer Module based on specific industry requirements, sample types, and desired analytical outcomes. Finally, we will look into emerging trends and innovations in XRF Spectrometer Module technology, including advancements in detector technology, software enhancements, and potential integration with AI and machine learning for predictive analytics. So, whether you are a professional in the field or just curious about XRF Spectrometer Modules, this guide will provide you with all the insights and knowledge you need to make informed decisions and stay ahead of the curve."

Types of XRF Spectrometers: ED-XRF vs. WD-XRF

X-ray Fluorescence (XRF) spectrometry is a powerful analytical technique used across various industries for quality control and material analysis. Two primary types of XRF spectrometers are Energy Dispersive XRF (ED-XRF) and Wavelength Dispersive XRF (WD-XRF), each with distinct operational principles, capabilities, and applications.

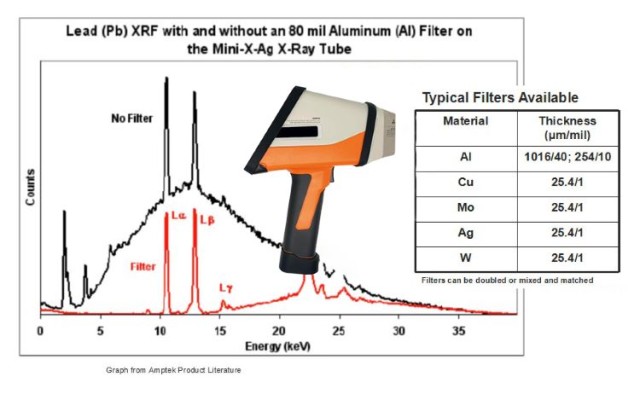

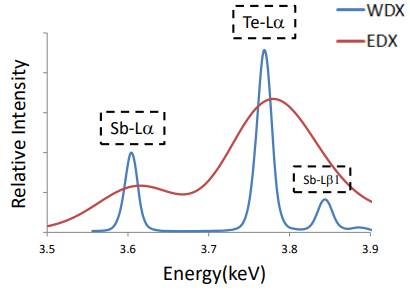

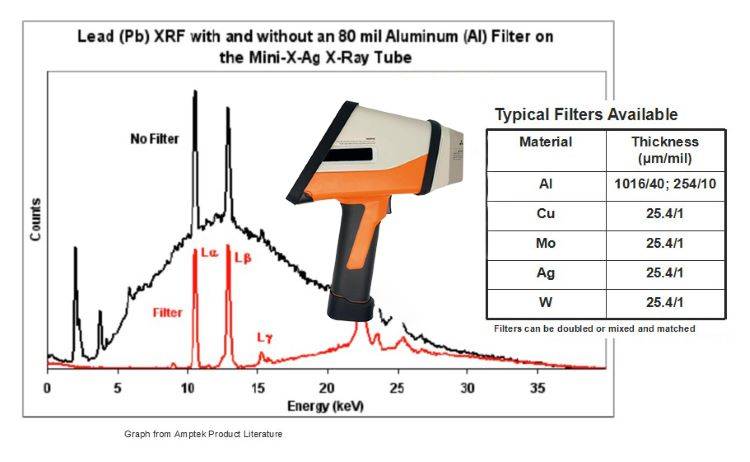

Energy Dispersive XRF (ED-XRF) is known for its simplicity and ease of use. This type of spectrometer utilizes a detector that simultaneously collects X-ray signals from multiple elements in a sample. The energy of the X-rays is used to identify and quantify the elements present. ED-XRF offers a resolution range from 150 eV to 600 eV, making it suitable for a broad spectrum of applications where high precision is not critical. Its straightforward operation and relatively lower cost make it a popular choice for routine analysis in industries such as cement, mining, and industrial minerals.

On the other hand, Wavelength Dispersive XRF (WD-XRF) provides superior resolution, ranging from 5 eV to 20 eV. This higher resolution is achieved through the use of a goniometer, which collects X-ray signals one at a time at different angles. The wavelength of the X-rays is used to determine the elements present in the sample. Although WD-XRF instruments are more complex and expensive, their high resolution makes them ideal for applications requiring detailed elemental analysis, such as in research laboratories and high-precision industrial settings.

In terms of application, both ED-XRF and WD-XRF are utilized in sectors like cement, metal ores, mineral ores, oil & gas, environmental, and geological applications. However, the choice between ED-XRF and WD-XRF often depends on the specific analytical requirements of the sample and the desired level of precision.

In summary, while ED-XRF offers a practical and cost-effective solution for many routine analytical needs, WD-XRF provides the enhanced resolution necessary for more demanding applications. Understanding the capabilities and limitations of each type of XRF spectrometer is crucial in selecting the right tool for specific analytical tasks, ensuring accurate and reliable results.

Key Features and Operational Capabilities of XRF Spectrometer Modules

XRF Spectrometer Modules are renowned for their robust 24/7 operational capability, which is crucial for continuous production line monitoring. This non-stop operation ensures that quality control processes are consistently maintained, allowing for uninterrupted production cycles and immediate feedback on product quality. The ability to operate continuously is particularly beneficial in high-volume manufacturing environments where downtime can lead to significant financial losses.

One of the standout features of XRF Spectrometer Modules is their non-destructive analysis capability. This feature is pivotal in preserving the integrity of samples while still providing accurate elemental analysis. Unlike destructive testing methods, XRF analysis allows for the same sample to be tested multiple times without degradation, which is essential for further analysis or processing. This non-destructive nature also means that valuable materials can be recycled or reused, contributing to cost savings and environmental sustainability.

The XRF Spectrometer Modules utilize advanced electronics and sophisticated mathematical algorithms to deliver rapid, accurate results. These modules can identify alloy grades within seconds, and with extended testing time, they can provide laboratory-level analysis results. The speed of analysis is a significant advantage in dynamic production environments where quick decisions based on real-time data are critical.

Integration of XRF Spectrometer Modules with robotic arms and automatic devices further enhances their operational efficiency. This integration allows for automated sample handling and analysis, reducing the need for human intervention and minimizing the potential for human error. The automated systems can be tailored to the specific layout and requirements of the factory production line, ensuring an efficient and effective detection solution.

In summary, the XRF Spectrometer Modules offer a powerful combination of continuous operation, non-destructive analysis, and rapid, accurate results. These features make them an indispensable tool for quality control in various industries, ensuring product integrity and compliance with industry standards. The integration with automation technologies further streamlines the analysis process, making it a highly reliable and efficient solution for modern manufacturing environments.

Applications of XRF Spectrometer Modules Across Industries

X-ray Fluorescence (XRF) Spectrometry is a versatile analytical technique that has found extensive applications across various industries, including cement, metal ores, mineral ores, oil & gas, environmental, and geological sectors. This technology provides non-destructive, accurate, and rapid elemental analysis, which is crucial for critical decision-making processes in exploration and quality control.

Cement Industry

In the cement industry, XRF spectrometers are essential for monitoring the composition of raw materials and finished products. The analysis helps in maintaining the quality and consistency of cement by ensuring that the correct proportions of limestone, clay, and other minerals are used. XRF technology enables real-time monitoring, which is crucial for adjusting the manufacturing process to meet specific standards and requirements.

Metal and Mineral Ores

For metal and mineral ore industries, XRF spectrometers play a vital role in exploration and ore grade control. They are used to analyze the elemental composition of ores, which helps in determining the economic viability of a mining site. Additionally, XRF is used for on-site analysis, allowing for immediate decisions regarding the extraction and processing of ores. This technology is particularly beneficial in the analysis of rare earth elements, which are critical components in various high-tech industries.

Oil & Gas Industry

In the oil & gas sector, XRF spectrometers are employed for the analysis of sulfur content in fuels, which is crucial for environmental compliance and equipment safety. They also analyze the elemental composition of drilling muds and other materials used in the extraction process, ensuring that they meet the necessary specifications.

Environmental Sector

The environmental industry utilizes XRF spectrometers for the analysis of soil, water, and air samples to monitor pollution levels and ensure compliance with environmental regulations. These instruments can detect a wide range of elements, making them ideal for environmental monitoring and remediation projects.

Geological Applications

Geologists rely on XRF spectrometers for geochemical testing, mapping, and mineral exploration. These instruments provide detailed elemental analysis of rock and soil samples, which is essential for understanding geological structures and mineral deposits. XRF technology is also used in core analyzers for exploration drilling, offering insights into the composition of subsurface materials.

Integration and Automation

Modern XRF spectrometer modules can be flexibly configured and integrated with robotic arms and automatic devices, forming efficient detection solutions tailored to the characteristics of different samples. These automated systems operate around the clock, providing real-time inspection and quality control on production lines without significant human intervention.

In conclusion, XRF spectrometer modules are indispensable tools in various industries, offering high-resolution elemental analysis that supports critical decision-making processes. Their ability to integrate with automation and operate continuously enhances their utility, making them a cornerstone of modern analytical laboratories and industrial processes.

Advanced Analysis Techniques with XRF Spectrometer Modules

X-ray fluorescence (XRF) spectrometry is a non-destructive analytical technique used to determine the elemental composition of materials. This method is widely applied in various industries, including mining, metal processing, and quality control, due to its accuracy, speed, and ease of use. The XRF spectrometer modules are equipped with advanced analysis techniques that enhance their performance and versatility, particularly in the analysis of light elements and the use of the fundamental parameters method.

Fundamental Parameters Method

The fundamental parameters method (FPM) is a mathematical approach used in XRF spectrometry that allows for the analysis of a sample without the need for calibration standards. This method is based on the fundamental physical properties of the sample and the excitation source, such as the X-ray tube. By calculating the interaction of X-rays with the sample, the FPM can predict the intensity of the emitted fluorescent X-rays, which correspond to the elemental composition of the sample.

The advantage of using the FPM is its applicability to a wide range of sample types and compositions without the need for extensive calibration. This makes it particularly useful in mining applications where samples can vary greatly in composition and where rapid, on-site analysis is crucial. For instance, the XRF60M, a handheld XRF mining analyzer, utilizes the FPM to provide on-site analysis of ore samples with minimal sample preparation, reducing assay times from days to minutes.

Analysis of Light Elements

XRF spectrometers are not only capable of analyzing heavy elements but also light elements, which is critical for understanding sample mineralogy. The analysis of light elements, such as magnesium (Mg), aluminum (Al), silicon (Si), and sulfur (S), requires specific instrument configurations and techniques due to their low atomic numbers and the challenges associated with exciting and detecting their characteristic X-rays.

Modern XRF spectrometers, like the XRF60M, are equipped with advanced electronics and detectors that allow for precise analysis of these light elements. This capability is particularly important in the analysis of minerals such as bauxite and limestone, where the presence and concentration of light elements significantly affect the quality and usability of the material.

Enhancing Analytical Precision

The combination of the fundamental parameters method and the capability to analyze light elements significantly enhances the analytical precision of XRF spectrometers. This precision is crucial in various applications, from ensuring the quality of raw materials in industrial processes to the accurate assessment of ore grades in mining.

In the mining industry, for example, the ability to quickly and accurately analyze ore samples for both heavy and light elements can lead to more efficient mining operations and better resource utilization. The XRF60M's ability to analyze an ore sample without the need for calibration standards and its precision in analyzing light elements make it an invaluable tool for mineral exploration and ore grade control.

In conclusion, the advanced analysis techniques employed in XRF spectrometer modules, such as the fundamental parameters method and the analysis of light elements, play a critical role in enhancing analytical precision and understanding sample mineralogy. These capabilities not only improve the efficiency and effectiveness of XRF spectrometry but also expand its applications across various industries, making it a versatile and indispensable analytical tool.

Integration of XRF Spectrometer Modules with Automation and Robotics

In the modern industrial landscape, the integration of XRF Spectrometer Modules with automation and robotics has revolutionized production line efficiency and accuracy. This advanced technology not only optimizes factory layouts but also significantly reduces human intervention, leading to cost savings and improved productivity.

Enhanced Efficiency and Accuracy

The integration of XRF Spectrometer Modules with robotic arms and automatic devices allows for continuous, real-time monitoring of product quality. Equipped with high-performance SDD detectors, these systems can quickly analyze and identify a variety of alloy grades, ensuring that each batch of products meets the required standards. This automated process eliminates the need for manual inspection, which is not only time-consuming but also prone to human error. The real-time display of element content helps in making immediate decisions regarding product quality, thereby enhancing the overall efficiency of the production line.

Easy Integration and Installation

Designed with a unique and user-friendly interface, these XRF Spectrometer Modules are easy to install on robotic arms or directly onto the production line. The availability of Ethernet (RJ-45) and USB interfaces facilitates seamless integration with existing factory networks, enabling remote operation and monitoring. The DC power interface ensures stable power supply, further supporting the uninterrupted operation of the system.

Low Maintenance and Quick Recovery of Costs

The rugged design of these modules, which includes features like dust-proof, moisture-proof, and vibration-proof capabilities, ensures low maintenance costs. They are built to withstand the harsh environmental conditions typically found in factory settings. The implementation of automated inspection solutions significantly reduces manual inspection costs, saving both time and improving the efficiency of product manufacturing. This rapid recovery of the cost of the online automatic detection equipment makes it a financially viable investment for factories.

24/7 Operation and Real-time Detection

One of the standout features of integrating XRF Spectrometer Modules with automation is the ability to operate 24/7. This continuous operation ensures that all products are inspected in real-time, leading to immediate detection of any defects or inconsistencies. This round-the-clock monitoring not only improves product quality but also enhances the sustainability of the production process by reducing waste and improving resource utilization.

In conclusion, the integration of XRF Spectrometer Modules with automation and robotics offers a multitude of benefits, including enhanced efficiency, accuracy, and reduced human intervention. This technology is a game-changer for industries looking to optimize their production processes and improve their bottom line.

Choosing the Right XRF Spectrometer Module for Specific Needs

Selecting the appropriate XRF Spectrometer Module is crucial for achieving accurate and efficient results in various industries. The choice primarily depends on the specific requirements of the industry, the type of samples being analyzed, and the desired analytical outcomes. XRF spectrometers generally fall into two categories: Energy Dispersive XRF (ED-XRF) and Wavelength Dispersive XRF (WD-XRF).

ED-XRF Spectrometers are known for their simplicity and ease of use. They can simultaneously collect signals from several elements, making them a versatile choice for quick analysis. The resolution of ED-XRF spectrometers typically ranges from 150 eV to 600 eV, which is suitable for many general applications. These instruments are ideal for industries that require rapid, non-destructive testing with minimal sample preparation, such as metal processing, scrap metal recycling, and quality control in manufacturing.

WD-XRF Spectrometers, on the other hand, are more complex and expensive. They collect one signal at a time at different angles using a goniometer, which results in significantly higher resolution, ranging from 5 eV to 20 eV. This high resolution makes WD-XRF spectrometers ideal for precise elemental analysis in industries where accuracy is paramount, such as cement, metal ores, mineral ores, and geological applications. The higher cost and complexity of WD-XRF are justified by their superior analytical capabilities and precision.

When choosing an XRF spectrometer module, consider factors such as resolution, portability, and ease of use. For on-site or field analysis, portable ED-XRF spectrometers are often the preferred choice due to their mobility and ease of operation. In contrast, WD-XRF spectrometers are typically used in laboratory settings where high precision and detailed analysis are required.

Additionally, the integration of XRF spectrometers with automation and robotics, as seen in the Scientific In-line XRF Spectrometer Module series, offers a significant advantage in industrial settings. These modules can be configured to work with robotic arms and automatic devices, forming an efficient detection solution that meets the specific needs of different samples on a production line. This integration allows for 24/7 operation, real-time inspection, and continuous quality control, which are essential for maintaining high standards in manufacturing and processing industries.

In conclusion, the selection of an XRF spectrometer module should be guided by the specific analytical needs of the industry, the types of samples to be analyzed, and the desired level of precision and speed. Whether it's the simplicity and versatility of ED-XRF or the high precision of WD-XRF, the right choice will significantly enhance the efficiency and effectiveness of elemental analysis in any application.

Future Trends and Innovations in XRF Spectrometer Module Technology

The field of XRF spectrometer technology is rapidly evolving, driven by advancements in detector technology, software enhancements, and the integration of AI and machine learning for predictive analytics. These developments are not only enhancing the capabilities of XRF spectrometers but also expanding their applications across various industries.

Advancements in Detector Technology

Recent innovations in detector technology have significantly improved the sensitivity and resolution of XRF spectrometers. For instance, the introduction of detectors with graphene windows has enabled the detection of elements at very low concentrations, even those typically found in trace amounts in the Earth's crust. This enhancement is particularly beneficial in mineral exploration and ore grade control, where the ability to detect subtle geochemical irregularities can lead to more efficient resource extraction.

Software Enhancements

Software plays a crucial role in the functionality and efficiency of XRF spectrometers. Modern XRF analyzers are equipped with intelligent software that features user-friendly interfaces and customizable data fields. These software solutions allow for the remote operation of analyzers, data transfer, and viewing of sample readings via WiFi, enhancing the flexibility and accessibility of XRF technology. The AXRSPEC PC software, for example, enables users to control the analyzer from a computer, streamlining the analytical process and reducing the need for on-site analysis.

Integration with AI and Machine Learning

The integration of AI and machine learning into XRF spectrometer technology is a significant trend that is revolutionizing the way data is analyzed and interpreted. These technologies enable predictive analytics, allowing for the prediction of outcomes based on historical data. In the context of XRF spectrometry, this can lead to more accurate predictions of ore grades and mineral compositions, thereby optimizing exploration and extraction processes. AI algorithms can also help in automating data analysis, reducing the time and effort required to interpret results.

Applications and Benefits

These technological advancements are broadening the applications of XRF spectrometers in various sectors. In mineral exploration, for instance, the rapid identification of significant findings can lead to substantial time and resource savings. The ability to conduct swift qualitative screenings directly in the field minimizes the unpredictability of excavation and reduces the need for outsourcing samples to external testing labs. This not only boosts productivity but also enhances sustainability by reducing laboratory expenses and turnaround times.

In conclusion, the future of XRF spectrometer module technology looks promising, with ongoing innovations poised to further enhance its capabilities and applications. The integration of advanced detectors, intelligent software, and AI technologies is set to transform the landscape of metal analysis, making it more efficient, accurate, and adaptable to the evolving needs of various industries.

Related Products

Related Articles

- What is xrf analysis and how to making pressed xrf pellets

- Techniques for Sample Preparation in X-Ray Fluorescence Analysis: Pressed and Loose Powder Methods

- How to Choose the Right XRF Pellet Press for Your Needs

- How To Turn XRF analysis sample preparation Into Success

- Dilution Ratios for XRF Pelletising Finding the Optimal Balance