Introduction to XRF analysis

X-ray fluorescence (XRF) analysis is a non-destructive analytical technique used to determine the elemental composition of solid, liquid, and powdered samples. The technique is based on the principle that when an X-ray beam is directed at a sample, the atoms in the sample absorb some of the X-ray energy and then emit it as secondary X-rays with energies characteristic of the elements present. XRF analysis is widely used in a range of industries, including mining, environmental monitoring, and materials science, to identify and quantify the elements present in a sample.

Table of Contents

Liquid Sample Preparation

Preparing liquid samples for XRF analysis requires a different approach than solid samples. Liquid samples are often poured into a cup and sealed with a suitable film. The film provides enough support and transmission while keeping the sample free of contaminants.

Evaporation Method

One method of preparing liquid samples for XRF analysis is to evaporate the liquid to dryness and then pelletise the resulting solid residue. This approach is suitable for samples that do not contain any volatile components. The residue is then ground to a fine particle size before being mixed with a binder and pelletised.

Binder Method

Another approach is to mix the liquid with a suitable binder before pelletising. This method is ideal for liquid samples that contain volatile components. The binder acts as a stabiliser to prevent the sample from evaporating during the pelletising process. Tips and tricks for successful pelletising of liquid samples include choosing an appropriate binder, optimising the mixing ratio, and selecting the right pellet die size.

Choosing an Appropriate Binder

Choosing the right binder is crucial for the successful preparation of liquid samples. Cellulose/wax mixtures are commonly used as binders for liquid samples. This binder will homogenize with the sample and bind the powders together during the mixing and pressing stages. For acidic or corrosive solutions, acid-resistant binders are recommended to avoid contamination of the sample.

Optimising the Mixing Ratio

The mixing ratio between the liquid sample and binder is also important and should be optimised for each sample. The most common sample dilution ratio is 20/30% binder to sample ratio. Using too much binder can cause weak pellets that are prone to breakage, while using too little binder can result in loose powders that can contaminate the spectrometer and skew the results.

Selecting the Right Pellet Die Size

Selecting the right pellet die size is crucial for the successful preparation of liquid samples. The pellet die size should match the cup size to ensure a tight fit, preventing any leakage of the sample. It is also important to ensure that the pellets are thoroughly dried before analysis to avoid interference from moisture. Organic solvents may require a longer drying time compared to other liquids.

In conclusion, preparing liquid samples for XRF analysis requires proper sample preparation techniques, which includes choosing the right binder, optimising the mixing ratio, selecting the right pellet die size, and ensuring that the pellets are thoroughly dried before analysis. By following these tips and tricks, XRF users can ensure accurate and reliable analysis of liquid samples.

Solid Sample Preparation

Solid sample preparation is a critical step in XRF pelletising for solid samples. The accuracy and reliability of the XRF analysis depend on the quality of the sample preparation. Here are some tips and tricks to ensure the best possible sample preparation:

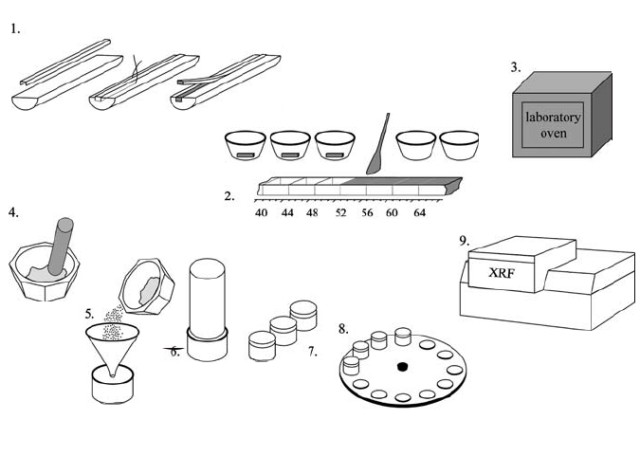

Grinding the Sample

The first step in solid sample preparation is to grind the sample to a fine particle size. The sample should be ground to a particle size of <75µm, but <50µm is ideal. Depending on the sample type and volume, this can usually be accomplished with a few minutes of grinding with a typical ring and puck pulverizing mill. Small particle size is an important factor in producing pellets that provide the best analytical results because it effects how the sample will compress and bind together when pressed. More importantly, samples with larger or variable particle sizes can lead to heterogeneities in the sample.

Mixing with a Binder

The use of a binder, such as wax or cellulose, is recommended to ensure that the pellet is stable and does not crumble during analysis. The amount of binder should be carefully chosen to avoid interference with the analysis. The binder should be thoroughly mixed with the sample to achieve a homogenous mixture.

Dilution Ratio

The dilution ratio is also an important factor in solid sample preparation. The dilution ratio should be chosen based on the concentration of the elements of interest in the sample. A higher dilution ratio is necessary for samples with higher concentrations of elements.

Pelletising

The next step is to pelletise the sample. The process involves compressing the sample into a small disc-shaped pellet that is then placed into the XRF instrument. The pressure used to compress the pellet should be optimized to ensure a uniform density and avoid cracking. The size of the pellet should be chosen based on the XRF instrument used, with larger pellets being suitable for instruments with higher power.

Sample Contamination

An additional consideration in solid sample preparation is sample contamination. Samples can become contaminated from a variety of sources, such as the grinding vessel, the binder, or the pressing die. To avoid contamination, it is important to use clean grinding vessels, binders, and pressing dies for each sample.

In conclusion, solid sample preparation is a crucial step in XRF pelletising for solid samples. The accuracy and reliability of the XRF analysis depend on the quality of the sample preparation. Therefore, careful attention should be given to grinding the sample to a fine particle size, mixing with a binder, selecting the appropriate dilution ratio, and avoiding sample contamination.

Pressed Pellets for XRF Analysis

Pressed pellets are a popular form of sample preparation for XRF analysis of solid samples. To create high-quality pellets for XRF analysis, it is important to follow some key tips and tricks.

Particle Size

The first step in pellet preparation is to ensure that the sample is ground to an appropriate particle size. Samples with a particle size of <50µm, or <75µm, are suitable for pelletising, as smaller particle sizes improve sample homogeneity and consistency.

Pressure

After the sample has been mixed with the binding agent, it is added to a die to be pressed. The sample is usually pressed with a hydraulic sample press, and the pressure applied through this instrument needs to be enough for the binder to recrystallize and for the sample to be completely compressed. Most samples will require pressing for 1-2 minutes, under 25-35T of pressure to ensure no void spaces are present in the pellet.

Thickness

The thickness of pressed pellets is also crucial for effective analysis. If a sample is too thick, the X-rays will not be able to penetrate it up to a certain point. Because XRF analysis relies on emitted X-rays reaching the detector, the sample must be infinitely thick to the X-rays.

Choosing the right binder

Choosing the right binder is crucial to ensuring sample integrity during the pelletising process. Common binders include wax, polyethylene, and cellulose, each with its own advantages and disadvantages. Wax binders are ideal for samples that do not bind well or break up easily, while polyethylene and cellulose binders work well for most samples. The right binder should be selected based on the properties of the sample being analysed.

Handling and storage

Handling and storing the pellets with care is essential to prevent damage or contamination. Pellets should be handled with clean gloves and stored in sealed containers to prevent moisture uptake and contamination.

Pressing powder samples with a pellet die

If your lab will predominantly be pressing pellets for KBr pellets for FT-IR, for example, the material is predominantly KBr salt with a small percentage of the analysis material added in. The two materials should be well mixed without allowing too much moisture to be absorbed. A load of 10 tonnes applied through a 13 mm diameter pellet die is usually more than adequate for the task.

Molding polymer films with a film maker

Analysis of polymers using spectroscopic techniques often requires a thin film to be produced. This can be achieved with heat and pressure using a heated platen and a film-making mold to set the thickness exactly.

In conclusion, producing high-quality pressed pellets for XRF analysis requires accuracy and specific measurements. By following the tips and tricks outlined above, accurate and reliable results can be achieved.

Fused Beads for XRF Analysis

X-ray fluorescence (XRF) is a popular analytical technique used in the laboratory to determine the elemental composition of solid materials. One of the most important steps in preparing solid samples for XRF analysis is pelletizing. Pelletizing involves fusing a powdered sample into a solid bead using a fluxing agent. This process is critical in ensuring sample homogenization and reducing particle size effects that can affect the accuracy of the XRF analysis.

Advantages of Fused Beads

Fused beads are preferred over pressed pellets because they offer better homogeneity and are less prone to contamination. Fused beads are prepared by melting the sample and flux in a platinum, zirconium or graphite crucible to create a glass disk for XRF analysis. Fused beads are ideal for the analysis of small quantities of powdered samples that are difficult to pelletize.

Selecting the Right Fluxing Agent

Selecting the right fluxing agent is essential for successful XRF pelletizing. The fluxing agent should melt at a lower temperature than the sample and the bead should be stable at the fusion temperature. Lithium tetraborate, sodium tetraborate, and lithium metaborate are commonly used fluxing agents in XRF analysis.

Optimizing the Fusion Conditions

Optimizing the fusion conditions is important to obtain high-quality fused beads. The sample-to-flux ratio should be appropriate, and the fusion temperature should not be too high to avoid the loss of volatile elements. The fusion temperature should be optimized to ensure complete fusion of the sample and flux. It is important to monitor the furnace temperature during the fusion process to ensure that the temperature is stable.

Using High-Quality Sample Powders

Using high-quality sample powders is essential for successful XRF pelletizing. The sample should be finely ground and homogenized to ensure that the analysis is representative. The sample should be free from contamination and should not contain any other elements that may interfere with the analysis. The sample should be dried to remove any moisture before pelletizing.

In conclusion, fused beads are ideal for XRF analysis of solid samples. The advantages of fused beads include better homogeneity and less contamination. Selecting the right fluxing agent, optimizing the fusion conditions, and using high-quality sample powders are essential for successful XRF pelletizing. By following these tips and tricks, researchers can obtain high-quality fused beads that are ideal for XRF analysis of solid samples.

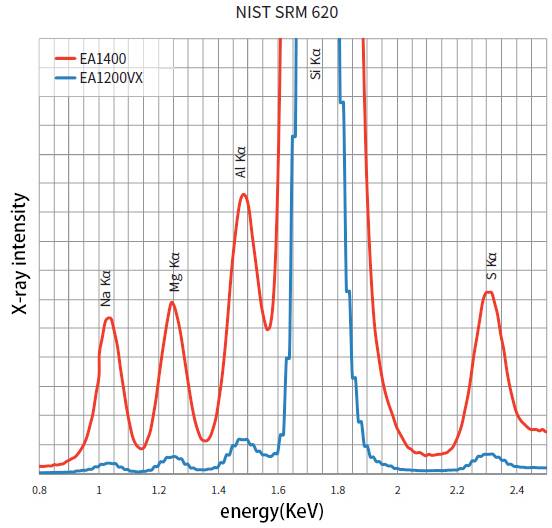

Factors Affecting XRF Analysis

Sample Preparation

Sample preparation is critical for accurate and precise results in XRF analysis. Pelletising is a popular technique for solid sample preparation, but factors affecting the quality of the pellet can affect the accuracy of the analysis. The quality of the pellet is determined by the homogeneity, density, and stability of the sample. The homogeneity of the sample ensures that the pellet represents the entire sample. The density of the pellet affects the penetration depth of the X-ray beam, and the stability of the pellet ensures that it does not crumble during analysis. Factors affecting the quality of the pellet include the particle size and shape of the sample, the pressure applied during pelletising, the duration of the pressure application, and the use of a binder.

Pellet Thickness

The thickness of the pellet is important to achieve the best analytical results. The pellet must be infinitely thick to the X-ray beam for all of the elements that are being measured. The problem arises when the escape depth of a particular element is larger than the thickness of the pellet. In general, you should make sure your pressed pellet is thicker than the escape depth of the highest energy element you want to measure.

Sample Contamination

Sample contamination is an additional consideration in the preparation of high-quality pressed pellets for XRF analysis. Contamination usually occurs during the sample grinding process and originates from two main sources: the sample preparation device and sample to sample cross-contamination. Sample pulverizers are the sample preparation devices that have the potential to contribute the most contamination to a sample. Contamination from the die surface is a concern when pelletizing samples. To prevent contamination, it is recommended to clean the die surface before each pelletization and to start with lower concentrations.

Preparation of Calibration Standards and Routine Samples

It is critical that all calibration standards and unknown samples be prepared in the same manner to ensure the accuracy of your analysis. Given this requirement, you will need to develop a method that will address the issues detailed in this article for the full range of calibration materials and routine samples that you will need to analyze in your laboratory.

Pressing Techniques

Manual and automatic press machines are available for pelletizing with flat and cylinder-type dies. X-ray intensity changes depending on pelletization pressure. When pressure is released after pelletization, the compressed ring and sample can slowly expand over time, causing height differences between the sample surface and ring, resulting in a change in X-ray intensity or even leading to the breakage of the pellet. Sample preparation reproducibility can be further improved by pelletizing the sample with a pressure at which X-ray intensity saturates.

Conclusion

The factors discussed above are critical considerations for XRF analysis. Good method development coupled with attention to detail and consistency can minimize errors in pelletizing samples, reducing the risk of contamination and ensuring accurate and precise results.

Importance of High-Quality XRF Pellet Die

When it comes to obtaining accurate results through X-ray fluorescence (XRF) analysis of solid samples, it is crucial to prepare high-quality XRF pellets. Pelletising solid samples for XRF analysis using a pellet press is a common technique employed in many laboratories. However, the quality of the pellet die used in the process significantly affects the overall quality of the pellet produced.

Precision Machining of the Pellet Die

A high-quality XRF pellet die is essential to achieve a uniform and dense pellet that will provide consistent and reliable results. The die must be precisely machined to provide a smooth and flat surface, which ensures that the sample is evenly distributed and compressed during the pressing process. A properly machined die can also help to prevent unwanted contamination of the sample by reducing the risk of wear and tear on the die caused by repeated use.

Prevention of Contamination

Contamination can severely affect the accuracy of XRF analysis, which means that it is essential to use a high-quality pellet die that minimizes the risk of contamination. The use of a high-quality die can also extend the lifespan of the pellet press by reducing the frequency of die replacement.

Accurate and Reliable Results

Investing in a high-quality XRF pellet die is necessary to ensure accurate and reliable XRF analysis of solid samples. A high-quality die will produce pellets that are uniform and dense, which will provide consistent and reliable results. The use of a high-quality die also reduces the risk of contamination, which can affect the overall accuracy of the analysis.

Conclusion

In conclusion, the importance of a high-quality XRF pellet die cannot be overstated. The precision machining of the die ensures that the sample is evenly distributed and compressed during the pressing process. The use of a high-quality die also minimizes the risk of contamination, which can severely affect the accuracy of XRF analysis. Investing in a high-quality XRF pellet die is necessary to obtain accurate and reliable results through X-ray fluorescence analysis of solid samples.

Correct Load for XRF Pellet Pressing

When it comes to achieving accurate and consistent XRF analysis results for solid samples, one of the key factors is determining the correct load for XRF pellet pressing. The load refers to the amount of pressure applied to the sample during the pelletizing process and can vary depending on the type and amount of material being analyzed. Here are some tips and tricks for determining the correct load:

Conduct Trial Runs

Conducting trial runs is one of the most effective ways to determine the optimal load for a particular sample. This involves testing different loads and observing the quality of the resulting pellet, as well as the integrity of the XRF equipment. By starting with a lower load and gradually increasing it, you can find the load that provides the best balance between good pellet formation and minimal damage to the equipment.

Adjust Load Based on Sample Hardness and Particle Size

The hardness and particle size of the sample can also affect the optimal load for XRF pellet pressing. For harder and larger samples, a higher load may be required to achieve the desired pellet density. On the other hand, softer and finer samples may require a lower load to avoid crushing or deforming the particles.

Ensure Even Sample Distribution

Another important factor in achieving the correct load for XRF pellet pressing is ensuring that the sample is evenly distributed within the pellet die. Uneven sample distribution can result in uneven pressure distribution, which can lead to poor pellet formation. To ensure even sample distribution, mix the sample thoroughly and pack it evenly into the pellet die.

Consider the Maximum Rated Load of the Pellet Die

Pellet dies usually have a maximum rated load that limits the pressure to under 1000 MPa. Therefore, it's important to consider the maximum load of the pellet die when determining the correct load for XRF pellet pressing. Using too much load can damage the pellet die and the XRF equipment, while using too little can result in poor pellet formation.

By following these tips and tricks, laboratory professionals can determine the correct load for XRF pellet pressing and achieve accurate and reliable XRF analysis results for solid samples.

Manual vs Automatic XRF Pellet Press

In the field of laboratory analysis, XRF Pelletising for Solid Samples is a critical process that involves the creation of a solid sample pellet for analysis using X-ray fluorescence (XRF) spectroscopy. There are two methods of creating these pellets, namely manual and automatic XRF pellet press.

Manual XRF Pellet Press

Manual pelletising requires a skilled technician to apply force to a sample using a hydraulic press. This process can be time-consuming and labour-intensive. However, it can be more cost-effective in terms of equipment and maintenance.

Manual pelletising is ideal for small-scale testing where a technician can give individual attention to each sample. It is also suitable for labs with a limited budget and where accuracy is not critical.

Automatic XRF Pellet Press

Automatic pelletising, on the other hand, uses a machine to create pellets automatically. In terms of speed and precision, automatic pelletising is the better option. It eliminates the need for a skilled technician, ensuring consistent results each time.

Automatic pelletising is ideal for industrial XRF applications and other laboratory sample manipulation activities, as well as small and large-scale manufacturing practices, including hot embossing, laminating and melting polymers for thin films.

Choosing between Manual and Automatic XRF Pellet Press

The choice between manual and automatic XRF pellet press will depend on the laboratory's specific needs and budget. For labs with a limited budget and where accuracy is not critical, manual pelletising may be the best option. However, for busy laboratories with a high volume of samples to analyze, an automatic pellet press would be more efficient.

It is important to consider the type of sample being analyzed, as some samples may require a specific pelletising method. Regardless of the method chosen, proper maintenance and calibration of the equipment is crucial for accurate and reliable results.

Conclusion

In conclusion, understanding the differences between manual and automatic XRF pellet press is crucial for laboratories seeking to achieve accurate and reliable results in the field of laboratory analysis. The choice between the two methods will depend on the laboratory's specific needs and budget. Proper maintenance and calibration of the equipment is crucial for accurate and reliable results.

Related Products

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- XRF Boric Acid Lab Powder Pellet Pressing Mold for Laboratory Use