Introduction to Rotary Evaporators

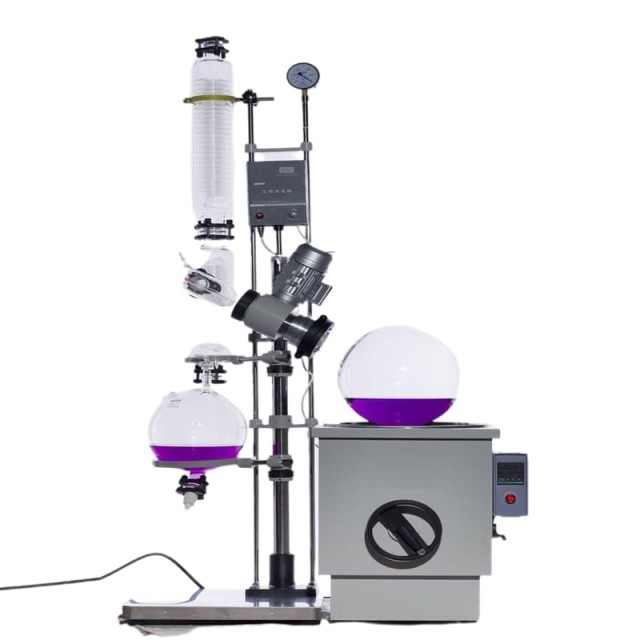

Rotary evaporators are essential laboratory equipment used in the process of separating solvents from samples. These devices work by evaporating the solvent from the sample under a reduced pressure and controlled temperature. The evaporated solvent is then condensed and collected for further use or disposal. Rotary evaporators offer several advantages over traditional distillation methods, including faster evaporation times, lower boiling temperatures, and gentle cooking of samples to preserve their taste and aroma. Additionally, rotary evaporators are useful for solvent recovery, purification of plant extracts and essential oils, and distillation of complex mixtures. Overall, rotary evaporators are an indispensable tool for any laboratory that deals with sample preparation and purification.

Table of Contents

- Introduction to Rotary Evaporators

- Advantages of Using a Rotary Evaporator

- Lower Boiling Temperatures

- Faster Evaporation of Solvent

- Fewer Operations

- Rotary Evaporators Suppress Bumping

- Benefits of Rotary Evaporator Cooking

- Heated Water/Oil Bath for Increased Distillation Rate

- Rotating Feature for Faster Evaporation

- Visual Monitoring and Adjustment

- Totally Sealed Glass Hardware for Zero Wastage

- Conclusion on the Benefits of Rotary Evaporator

Advantages of Using a Rotary Evaporator

Rotary evaporators have become an essential tool in many laboratory settings due to their numerous benefits. In this section, we will discuss the advantages of using a rotary evaporator in detail.

Efficient and Effective Separation Process

One of the main advantages of using a rotary evaporator is that it allows for a more efficient and effective separation process. By utilizing a rotary evaporator, scientists can quickly and easily evaporate solvents, leaving behind a purified sample. This process is made possible by the vacuum system that reduces the pressure within the evaporator system, which ensures that the solvent boils at a lower temperature than usual. The rotating flask increases the surface area of the liquid, which in turn increases the rate of evaporation.

Reduced Risk of Contamination

Using a rotary evaporator can help to reduce the risk of contamination as it allows for a closed system, minimizing the likelihood of exposure to outside elements. The instrument is also designed to be user-friendly, allowing for easy operation and maintenance.

Versatile Applications

The instrument is highly versatile and can be used in a variety of applications, including the extraction of volatile compounds, the concentration of samples, and the removal of solvents from reaction mixtures. The feeding system of a rotary evaporator is continuous feeding, which improves the working efficiency of the evaporation system. It is suitable for reflux operation, rapid evaporation of large amounts of solvent, concentration of trace components and reaction processes that require stirring.

Saves Energy

Another advantage of using a rotary evaporator is that it saves a great deal of energy. This is because it negates the need to heat the solution to the boiling point. Instead, it lowers the pressure of the fluid in such a way as to make its boiling point lower. For this reason, you will not have to dig deep into your pocket to operate it.

Convenient Controls

Rotary evaporators come equipped with a set of convenient controls for your use and leverage. You also need not possess a huge expertise to be able to have your way in them at all. The built-in lifting motor can automatically raise the flask to a position above the heating pot when the power is turned off.

Highly Effective

All said and done, the rotary evaporator is highly effective. It does the job of extracting solvents well and with minimal dangers and damages. It is an essential separation equipment, which can remove a volatile solvent from a liquid mixture through evaporation and condensation.

In conclusion, the benefits of using a rotary evaporator make it an essential tool in many laboratory settings, contributing to the efficiency and accuracy of various scientific processes.

Lower Boiling Temperatures

Rotary evaporators are known for their ability to distill solvents from samples by reducing the boiling point of the solvent. This is achieved by adding a sample to a rotating flask that is heated by a water bath, which causes the solvent to evaporate. The vapor is then condensed and collected in a separate flask. The lower boiling temperature provided by the rotary evaporator ensures that the sample is not damaged during the distillation process.

One of the main benefits of using a rotary evaporator is its ability to distill heat-sensitive compounds that would otherwise decompose at higher temperatures. By using a lower boiling temperature, the sample is protected from heat damage, allowing researchers to obtain accurate results without compromising the quality of the sample.

Another benefit of using a rotary evaporator is the ability to recover solvents, which can be costly to replace. The lower boiling temperature provided by the rotary evaporator ensures that the solvent is evaporated efficiently and accurately, allowing researchers to recover almost 100% of the solvent.

To achieve a lower boiling temperature, the rotary evaporator needs to be operated under a vacuum. This lowers the ambient pressure, which in turn lowers the boiling point of the solvent. Placing a liquid mixture under vacuum enables the distillation process to occur at a lower temperature. This lowers the liquid boiling point, increases the rate of distillation, and reduces exposure of temperature-sensitive components.

To maximize solvent recovery, it is important to use an evaporator with a high degree of vacuum control and integrity within the air seals and gaskets throughout the vacuum line. This helps to prevent air within the rotary evaporator from saturating with the solvent, which can cause solvent loss.

In addition to solvent recovery, the lower boiling temperature provided by the rotary evaporator has a wide range of applications in the chemical, pharmaceutical, and food industries. It is used in the extraction of essential oils, purification of natural products, and concentration of flavors and fragrances.

In conclusion, the lower boiling temperature provided by the rotary evaporator is one of its key benefits, allowing for efficient and gentle distillation of solvents, preservation of heat-sensitive compounds, and recovery of solvents. Its applications are varied and essential to many industries.

Faster Evaporation of Solvent

A rotary evaporator is a highly effective tool used for the distillation and separation of liquids in laboratory settings. One of the primary benefits of using a rotary evaporator is that it facilitates faster evaporation of solvents.

How Does a Rotary Evaporator Facilitate Faster Evaporation of Solvents?

The rotary evaporator uses a rotating flask to apply heat to the sample, which increases the surface area of the sample and accelerates the evaporation process. In addition, the constant rotation of the flask ensures that the sample is uniformly heated, which further accelerates the evaporation process.

Benefits of Faster Evaporation of Solvents

The faster evaporation of solvents provided by the rotary evaporator is particularly important in laboratory settings where time is of the essence. By using a rotary evaporator, scientists can significantly reduce the amount of time required for the evaporation process, allowing them to focus on other critical tasks.

In addition, the reduced evaporation time minimizes the risk of sample degradation, ensuring that the end product is of the highest possible quality. This is an important consideration in laboratory settings where the quality of the sample is critical to the success of the experiment.

Comparison with Traditional Distillation

The traditional distillation method is less efficient and accurate than a rotary evaporator. When using the distillation method, a mixture is heated to the temperature at which one component will boil. Then the vapor from the hot mixture is collected and recondensed into liquid, which is a relatively slow process. However, many kinds of mixtures cannot be separated by this method. Therefore, compared to traditional distillation, a rotary evaporator is more widely used in the chemical laboratories, industrial, bio-pharmaceutical, and food-making fields.

Conclusion

In conclusion, the use of a rotary evaporator is a highly effective way to increase productivity in the laboratory and obtain superior samples. The faster evaporation of solvents provided by the rotary evaporator is a significant advantage over traditional distillation methods, making it an essential tool in laboratory settings where time is of the essence.

Fewer Operations

One of the biggest benefits of using a rotary evaporator is the ability to perform multiple operations simultaneously, which ultimately saves time and increases efficiency in the laboratory. Here are the step-by-step details of how a rotary evaporator performs fewer operations:

1. Heating and Evaporating

The rotary evaporator works by rotating the sample flask, which is partially immersed in a heated water bath, while a vacuum is applied to the system. This rotation and vacuum application allow the solvent to evaporate from the sample, leaving behind the desired compound. By doing this, the rotary evaporator eliminates the need for a separate heating apparatus and vacuum pump.

2. Recovery and Reuse of Solvent

Another benefit of the rotary evaporator is that it allows for the recovery and reuse of solvents. The device is designed to collect the evaporated solvent in a separate flask, which can then be reused for future experiments. This feature significantly reduces the need for fresh solvent, saving both time and money.

3. Handling of Sample Types and Sizes

The rotary evaporator can handle a wide range of sample types and sizes, from small volumes to large batches, and from volatile to non-volatile compounds. This means that the device is versatile and can be used for a variety of laboratory applications, including chemical synthesis, product purification, and sample preparation for analysis.

4. Easy to Use

Rotary evaporators are simple to use and are commonly found in laboratories. The device is equipped with a digital display that allows the user to monitor and control rotation speed/temperature. Additionally, the KINTEK series rotary evaporators include on line sample adding through PTFE valve, motorized vertical lift, and stand-alone heating bath, which guarantees maximum safety in operations and easy maintenance.

In conclusion, the rotary evaporator is a valuable piece of equipment for any laboratory that requires efficient and reliable solvent evaporation. Its ability to perform multiple tasks simultaneously and handle a wide range of sample types and sizes makes it a versatile and cost-effective option for laboratory work. The device's innovative and ergonomic design, integrated vacuum control, efficient recovery of solvents, and comprehensive solution availability make it an optimal choice for any lab.

Rotary Evaporators Suppress Bumping

One of the primary benefits of using a rotary evaporator is that it helps to suppress bumping during the evaporation process. Bumping is a phenomenon that occurs when a boiling liquid produces bubbles that burst violently, causing the liquid to splatter. This can cause the loss of product and contamination of the surrounding environment.

How Rotary Evaporators Suppress Bumping

A rotary evaporator uses a rotating flask and a vacuum pump to create a low-pressure environment, which reduces the boiling point of the solvent. This helps to prevent bumping and ensures a more efficient evaporation process. The centrifugal force and the frictional force between the wall of the rotating flask and the liquid sample result in the formation of a thin film of warm solvent being spread over a large surface.

Other Factors That Affect Bumping

While a rotary evaporator can suppress bumping, there are other factors that can still lead to bumping. For example, certain solvent mixtures, such as ethanol and water, may have a higher tendency to bump. In such cases, precautions can be taken to avoid bumping, such as taking homogeneous phases into the evaporation and carefully regulating the strength of the vacuum or the bath temperature to provide for an even rate of evaporation.

Benefits of Suppressing Bumping

抑制颠簸对于防止产品损失和周围环境污染至关重要。它还提高了蒸发过程的效率,确保尽可能快速有效地从混合物中去除溶剂。此外,抑制颠簸可以回收溶剂,这些溶剂可以在未来的实验中重复使用,从而节省时间和金钱并促进可持续性。

结论

总之,使用旋转蒸发器有利于抑制蒸发过程中的颠簸。通过创造低压环境,旋转蒸发器降低了溶剂的沸点,这有助于防止碰撞并确保更高效的蒸发过程。抑制颠簸对于防止产品损失和周围环境污染非常重要,还可以回收溶剂,促进可持续性。

旋转蒸发器烹饪的好处

旋转蒸发器烹饪是一种通过提取和浓缩特定化合物来增强食物风味和质地的迷人方法。使用旋转蒸发器进行烹饪有很多好处,我们将在下面探讨。

保留原汁原味

旋转蒸发器烹饪的主要好处之一是该过程温和,并保留了食材的细腻风味。使用旋转蒸发器可确保保留食物的原始味道,并品尝到最纯净、最新鲜的食材风味。

提高生产效率

在烹饪中使用旋转蒸发器可以显着提高生产效率。蒸发器的蒸馏功能允许您通过蒸发和冷凝(液-气-液)过程,根据其不同的挥发性将给定的混合物分离成其组分,帮助您获得所需的液体。这个过程比传统的烹饪方法更快、更有效。

创造独特而复杂的风味

旋转蒸发器烹饪可让您创造出传统烹饪方法无法实现的独特而复杂的风味。通过提取和浓缩特定化合物,您可以制作水果精华,从草药中提取精油,甚至蒸馏酒精。这开辟了一个全新的烹饪世界,让您可以尝试不同的口味和质地。

改善成分质地

旋转蒸发器蒸煮还可以改善食材的质地。通过去除食物混合物中的水分,您可以浓缩非挥发性成分,从而获得更光滑、更精致的质地。这在酱汁中特别有用,因为酱汁需要浓郁的风味和光滑的质地。

复杂食品样品的处理

由于食品样品成分复杂,往往会对分析和检测造成干扰,因此往往提前采用旋转蒸发器处理。旋转蒸发器可以从香气、酒精、水和小风味分子等中分离糖、酸、色素和大多数苦味化合物。这使它成为食品科学家和厨师的宝贵工具。

总体而言,在烹饪中使用旋转蒸发器的好处是显着的。从保留原汁原味到创造独特而复杂的风味,旋转蒸发器烹饪是一种令人兴奋和创新的方式,将您的烹饪技巧提升到一个新的水平。

加热水浴/油浴,提高蒸馏速率

旋转蒸发器最重要的部件之一是加热的水或油浴。这为样品提供了稳定且可控的加热环境,防止样品过热并有助于保持其完整性。其工作原理如下:

加热浴缸

加热的水或油浴由内部加热元件加热。可以使用旋转蒸发器内置的温度控制器来控制浴槽的温度。温度可以设置为环境温度和被蒸馏溶剂沸点之间的任何温度。

提高蒸馏速率

加热的水浴或油浴为样品提供稳定和可控的加热环境,从而实现更快、更高效的蒸馏过程。浴槽温度的升高增加了溶剂蒸发的速度,这有助于加快整个蒸馏过程。

防止过热

加热的水浴或油浴也有助于防止样品过热。过热会导致样品降解,并可能导致所需化合物的损失。浴槽的受控加热环境确保样品受热均匀,不会过热。

保持样品完整性

保持样品的完整性对于获得准确可靠的结果至关重要。加热的水浴或油浴通过提供稳定和可控的加热环境来帮助保持样品的完整性。这有助于防止样品在蒸馏过程中分解或与其他化合物发生反应。

真空泵

除了加热的水浴或油浴外,真空泵通常与旋转蒸发器一起使用。真空泵降低了溶剂的沸点,从而进一步提高了蒸馏速率并降低了样品降解的风险。

总之,使用加热的水浴或油浴是旋转蒸发器的重要组成部分。它为样品提供了稳定可控的加热环境,有助于加快蒸馏过程,防止过热,保持样品的完整性。当与真空泵结合使用时,带有加热水浴或油浴的旋转蒸发器是从样品中去除溶剂的高效方法,并具有许多优点,使其成为实验室工作不可或缺的工具。

旋转功能,蒸发速度更快

旋转蒸发器是一种实验室设备,用于以更高效、更快速的方式蒸发溶剂。该设备具有旋转功能,可实现均匀加热并防止溶剂沸腾。旋转功能对于需要较长蒸发时间的样品特别有用,因为它允许连续蒸发而无需人工干预。

旋转功能的工作原理

该设备的旋转功能的工作原理是,在加热溶液的同时以特定速度旋转装有溶剂的烧瓶。该过程增加了溶剂的表面积,从而提高了蒸发速率。旋转运动搅动溶液和水浴,加速烧瓶和溶剂之间的热传递。

使用旋转功能的好处

使用旋转蒸发器的旋转功能的好处包括蒸发速度更快、溶剂分离更好以及能够使用各种溶剂。使用旋转蒸发器还可以降低污染风险并提高最终产品的纯度。

要考虑的因素

使用旋转蒸发器的旋转特性时,必须考虑转速和烧瓶的大小。精确控制蒸发瓶中的转速非常重要。溶剂和样品的一致性、烧瓶尺寸和液位等因素可能会改变 250–280 rpm 的推荐速度,以实现台式旋转蒸发器的最大湍流。

旋转蒸发器中烧瓶的大小也会影响混合物的表面积。理想情况下,蒸发瓶不应超过半满,既可以防止溢出,又要留出足够的液体表面积以进行有效蒸发。

如何使 Rotovap 过程更快

提高转速、容器尺寸、浴槽温度和真空度是使旋转蒸发器过程更快的方法。但是,每种情况都有注意事项。将转速提高到一定程度实际上会降低蒸发效率。如果烧瓶太满,使用太小的容器会增加溢出的机会。蒸发瓶不应超过半满,既要防止溢出,又要留出足够的液体表面积以有效蒸发。提高浴槽温度可能会损坏设备,也会增加发生事故的风险。

总之,旋转蒸发器的旋转特性是任何需要高效蒸发溶剂的实验室的必备工具。旋转运动搅动溶液和水浴,加速烧瓶和溶剂之间的热传递,从而提高蒸发速率。使用旋转功能时,必须考虑旋转速度和烧瓶的大小,以实现最大的湍流并防止溢出。

视觉监控和调整

使用旋转蒸发器的显著好处之一是能够直观地监控和调整过程。操作员可以实时观察过程,并根据需要进行调整,以确保最佳效率和结果。

实时观察

旋转蒸发器可以实时观察过程,使操作员能够密切监控过程。操作员可以看到溶剂是如何蒸发的,以及烧瓶中还剩下多少。此功能允许在与预期结果有任何偏差的情况下进行快速调整。

精确控制

实时监控过程的能力使操作员能够精确控制过程。此功能在处理易碎或敏感样品时尤为重要,因为它可以进行精确控制并降低损坏或丢失的风险。

提高准确性和可重复性

使用旋转蒸发器有助于提高结果的准确性和可重复性。根据需要监控和调整过程的能力允许在整个过程中保持一致和受控的条件。此功能可确保始终如一地使用相同的工艺条件,从而获得更准确和可重复的结果。

降低损坏或丢失的风险

旋转蒸发器的实时观察和精确控制功能也有助于降低损坏或丢失的风险。如果与预期结果有任何偏差,操作员可以迅速采取行动。此功能可确保在造成任何重大损坏之前立即停止该过程。

最佳效率

旋转蒸发器的视觉监控和调节功能确保了溶剂与样品分离的最佳效率。操作员可以观察过程并进行必要的调整,从而更快、更有效地从样品中分离溶剂。

总之,旋转蒸发仪的视觉监控和调整功能是一项关键功能,可实现精确控制、提高准确性和结果的可重复性。此功能还降低了损坏或丢失的风险,从而实现了从样品中分离溶剂的最佳效率。

全密封玻璃五金件,零浪费

旋转蒸发器是实验室设备,用于通过蒸发过程有效地去除样品中的溶剂。旋转蒸发器由旋转瓶、加热槽、冷凝器和收集瓶组成。旋转蒸发器的一个显着优点是其完全密封的玻璃硬件,可确保零浪费。

密封玻璃五金件的优点

旋转蒸发器的密封玻璃硬件确保溶剂保持在封闭系统中,从而减少操作人员暴露于有害烟雾中。它还确保样品不受环境污染,这会影响结果的准确性。当使用挥发性或昂贵的溶剂时,任何损失都可能代价高昂。密封的玻璃硬件确保不会浪费溶剂,使其成为一种具有成本效益的解决方案。

密封玻璃五金件的工作原理

旋转蒸发器的密封玻璃硬件通过创建一个封闭系统来工作,在该系统中,溶剂在不暴露于环境的情况下蒸发和冷凝。该过程是通过使用旋转烧瓶实现的,旋转烧瓶由加热浴加热。样品在烧瓶的内表面形成一层薄膜,该薄膜可有效蒸发。然后,蒸发的溶剂通过高效玻璃冷凝器冷却,并在收集瓶中回收。

优质玻璃器皿的重要性

旋转蒸发器中使用的玻璃器皿是完全密封玻璃硬件的重要组成部分。玻璃器皿必须是高质量的,以确保设备发挥最佳功能。它应该对实验中使用的化学品具有抵抗力,并且能够承受蒸发过程中使用的高温。定期清洁玻璃器皿对于确保样品或提取的材料没有污染至关重要。

关于旋转蒸发器优点的结论

总之,旋转蒸发器是一种必不可少的实验室设备,具有许多优点。它提供了一种更快、更有效的样品分离和纯化方法,沸腾温度更低,所需操作更少。真空泵和加热的水/油浴进一步提高了蒸发过程的精度和蒸馏速率。此外,旋转功能允许更快的蒸发,同时保持样品的味道和香气。密封的玻璃硬件最大限度地减少了浪费,使其成为环保的选择。总体而言,旋转蒸发器是任何希望改进其分离和纯化过程的实验室不可或缺的工具。

Related Products

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

Related Articles

- Water Circulating Vacuum Pumps: A Practical Guide for Laboratory Applications

- The Importance of Water Distillation in the Laboratory: Ensuring Purity and Quality for Accurate Results

- Step-by-Step Guide to Operating a Short Path Distillation Apparatus

- Exploring the Science Behind Rotary Evaporators: How They Work and Their Applications

- How to Choose and Optimize Water Circulating Vacuum Pumps for Your Lab