Introduction to Molecular Distillation

Definition and Principles

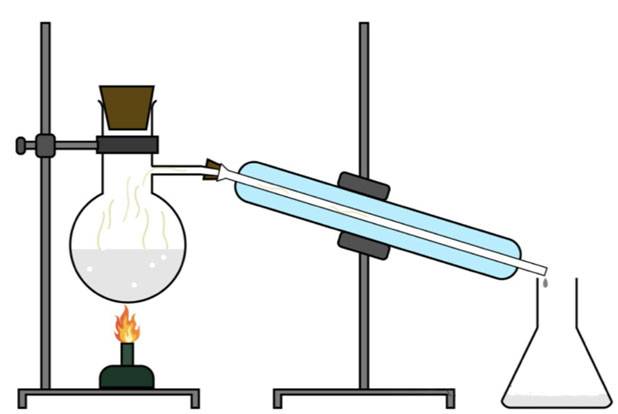

Molecular distillation, often referred to as short-range molecular distillation, is a specialized technique designed to separate heat-sensitive and high boiling point materials. Unlike traditional distillation methods that rely on differences in boiling points, molecular distillation operates based on the molecular mean free path. This principle allows it to effectively isolate compounds that would otherwise degrade under high temperatures, making it particularly advantageous for materials that are sensitive to heat.

The process involves creating a high vacuum environment, which reduces the pressure to such an extent that molecules can travel without colliding with other molecules over short distances. This absence of collisions enables the separation of materials based on their molecular weights rather than their boiling points. As a result, molecular distillation can handle substances that traditional distillation methods cannot, ensuring higher purity and maintaining the integrity of heat-sensitive compounds.

In essence, molecular distillation leverages the molecular mean free path to achieve separations that are not feasible with conventional distillation techniques. This makes it an invaluable tool in industries such as pharmaceuticals and food processing, where maintaining the quality and purity of products is paramount.

Comparison with Traditional Distillation

Traditional distillation operates by exploiting the differences in boiling points of various substances, a method that has been widely used for centuries. However, this approach can be limiting, especially when dealing with heat-sensitive materials or those with very close boiling points. In contrast, molecular distillation introduces a novel mechanism that relies on the molecular mean free path, rather than boiling point differences. This innovative technique is particularly effective for materials that require a more delicate handling due to their thermal sensitivity or complex chemical compositions.

Molecular distillation's reliance on molecular mean free path allows it to operate at significantly lower temperatures compared to traditional methods. This is achieved by creating a high vacuum environment, which minimizes the likelihood of thermal degradation. The process involves molecules traveling in straight lines until they collide with another molecule or the vessel wall, a principle that is fundamentally different from the phase change observed in traditional distillation. This difference in operation means that molecular distillation can achieve higher separation efficiencies, making it an ideal choice for industries requiring high-purity products, such as pharmaceuticals and food processing.

Moreover, the short heating times associated with molecular distillation, facilitated by the use of scrapers to create a uniform film on the evaporator surface, further enhance its effectiveness. This not only reduces the risk of material decomposition but also increases the overall efficiency of the distillation process. By focusing on the molecular mean free path, molecular distillation offers a more precise and controlled method of separation, setting it apart from traditional distillation techniques.

Key Advantages of Molecular Distillation

High Distillation Vacuum

Molecular distillation operates under a high vacuum environment, a critical factor that significantly enhances its effectiveness. This high vacuum is essential because it allows the distillation process to occur at significantly lower temperatures compared to traditional methods. By reducing the pressure, the boiling point of the liquid mixture is lowered, which in turn increases the rate of distillation. This is particularly advantageous when dealing with temperature-sensitive components, as it minimizes the risk of thermal degradation.

For instance, consider water, which boils at 212°F (100°C) at sea level. In Denver, CO, due to the lower atmospheric pressure, water boils at 203°F (95°C). This principle is applied in molecular distillation to create a vacuum that reduces the boiling points of the substances being distilled. This not only protects temperature-sensitive compounds from damage but also boosts productivity.

Under rough and fine vacuum conditions, the boiling points of the materials are greatly reduced, allowing operators to avoid thermal decomposition of their products. The wiping mechanism, which ensures a uniform film on the evaporator surface, further enhances evaporation efficiency, making the process both energy-efficient and highly effective.

Low Distillation Temperature

Molecular distillation operates at temperatures significantly lower than the boiling points of the raw materials, making it an ideal solution for heat-sensitive compounds. This is achieved through the utilization of a high vacuum environment, which reduces the pressure around the liquid mixture. As a result, the boiling point of the liquid is lowered, allowing for distillation to occur at much cooler temperatures. For instance, under standard atmospheric pressure, water boils at 212°F (100°C), but in a vacuum, it can boil at temperatures as low as 203°F (95°C), depending on the pressure reduction.

This low-temperature distillation method is particularly beneficial in industries where heat-sensitive materials are involved, such as in the processing of crude oil. In such cases, temperatures must be carefully controlled to prevent thermal cracking of high molecular weight components, which can lead to the formation of petroleum coke. This unwanted byproduct can cause significant operational issues, including the plugging of furnace tubes and distillation column piping. By maintaining distillation temperatures below 370 to 380 °C, molecular distillation ensures that these high molecular weight hydrocarbons remain intact, preserving the integrity of the final product.

Moreover, the low operating temperatures of molecular distillation minimize the risk of degradation or decomposition of temperature-sensitive components. This is crucial in applications where maintaining the chemical and physical properties of the distillate is essential, such as in the production of high-purity products in the food and pharmaceutical industries. The ability to distill materials at such low temperatures not only enhances the quality of the end product but also extends the operational life of the equipment by reducing thermal stress and wear.

In summary, the low distillation temperature achieved through molecular distillation provides a robust solution for handling heat-sensitive materials, ensuring efficient and safe processing without compromising the quality of the distillate.

High Separation Efficiency

Molecular distillation stands out due to its unique ability to achieve high separation efficiency, a characteristic that traditional distillation methods simply cannot match. The process's irreversible nature allows it to effectively separate materials that are otherwise impervious to traditional distillation techniques. This is particularly advantageous in industries where high-purity products are essential, such as in the food and pharmaceutical sectors.

In traditional distillation, the separation of materials is primarily based on differences in boiling points. However, this method often falls short when dealing with complex mixtures or heat-sensitive compounds. Molecular distillation, on the other hand, operates on the principle of molecular mean free range, enabling it to separate components that have very similar boiling points or are sensitive to high temperatures.

This superior separation capability is not just theoretical; it has practical implications in the production of high-quality, pure substances. For instance, in the pharmaceutical industry, the ability to extract pure active ingredients from complex mixtures is crucial for drug efficacy and safety. Similarly, in the food industry, the use of molecular distillation ensures that oils and fats are purified to meet stringent quality standards, enhancing the overall nutritional value and taste of the products.

The efficiency of molecular distillation is further underscored by its ability to operate under a high vacuum environment and at low temperatures, which minimizes the risk of thermal degradation. This makes it an ideal choice for processing delicate compounds that would otherwise be compromised by traditional high-temperature distillation methods.

In summary, the high separation efficiency of molecular distillation not only broadens the scope of materials that can be effectively processed but also ensures the production of high-purity products, making it an indispensable technique in industries that demand the utmost precision and quality.

Short Heating Time

The utilization of a scraper to create a uniform film on the evaporator surface significantly enhances the evaporation area. This enhancement not only expedites the distillation process but also mitigates the risks associated with material decomposition. By ensuring a consistent and efficient film, the scraper plays a pivotal role in minimizing the time required for heating, thereby preserving the integrity of heat-sensitive materials.

In molecular distillation, the short heating time is a critical factor that sets it apart from traditional distillation methods. Traditional methods often require prolonged exposure to high temperatures, which can lead to the degradation of sensitive compounds. In contrast, molecular distillation leverages the molecular mean free range to operate at temperatures far below the boiling points of the raw materials. This approach not only reduces the distillation time but also preserves the quality and stability of the distillate.

The efficiency of the scraper in forming a uniform film is crucial for the overall effectiveness of the distillation process. A uniform film ensures that all parts of the evaporator surface are equally exposed to the heating source, promoting even evaporation. This even distribution of heat reduces the likelihood of hotspots, where localized overheating could cause material decomposition. Consequently, the distillation process becomes more controlled and efficient, leading to higher-quality end products.

Moreover, the reduced heating time in molecular distillation contributes to energy savings and operational efficiency. By minimizing the duration of the heating phase, the process consumes less energy compared to traditional distillation methods. This energy-efficient approach not only lowers operational costs but also aligns with sustainable practices, making molecular distillation an environmentally friendly choice for industries dealing with heat-sensitive materials.

Related Products

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Double Plate Heating Press Mold for Lab

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- 20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

Related Articles

- Features and Precautions of Laboratory Water Bath Equipment

- Comprehensive Guide to Thermostatic Water Baths

- Electric Heating Systems(3): Understanding, Benefits, and Applications

- Choosing the Right Heating Method for Laboratory Experiments

- Preparation and Finishing Work for Using a Low-Temperature Thermostatic Reaction Bath