Importance of Molecular Distillation Equipment

Role in Enhancing Purity

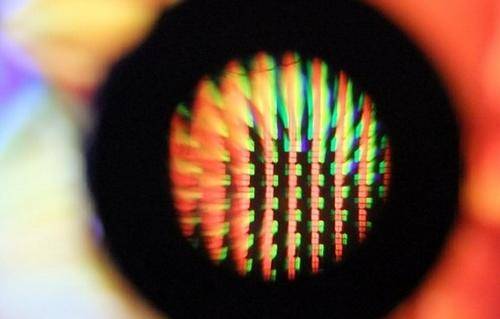

Molecular distillation equipment plays a pivotal role in refining liquid crystal materials, significantly enhancing their purity. This process is essential for producing high-quality displays in various electronic devices, including smartphones and televisions. By meticulously separating impurities at the molecular level, this technology ensures that the end products meet stringent purity standards, which are critical for optimal display performance.

The precision of molecular distillation not only guarantees the removal of harmful contaminants but also preserves the unique optical properties of liquid crystal materials. This dual benefit is crucial for maintaining the clarity and responsiveness of display screens, which are paramount for user experience in modern electronic devices.

Moreover, the efficiency of molecular distillation in purifying liquid crystal materials directly correlates with the energy efficiency of the production process. By minimizing waste and maximizing the recovery of valuable materials, this technology aligns with both economic and environmental sustainability goals, making it an indispensable tool in the modern manufacturing landscape.

Energy Efficiency

Molecular distillation equipment plays a pivotal role in optimizing energy consumption within the production of liquid crystal materials. By effectively capturing and reusing volatile solvents and impurities, this technology significantly reduces the overall energy expenditure. This not only lowers operational costs but also contributes to a more sustainable industrial practice. The process of energy recovery and reuse is meticulously designed to minimize waste and maximize the efficiency of energy use, aligning perfectly with contemporary environmental sustainability goals.

Moreover, the integration of molecular distillation equipment in the production line ensures that energy is utilized in the most efficient manner possible. This is achieved through advanced recovery systems that capture and repurpose energy that would otherwise be lost, thereby enhancing the overall energy efficiency of the manufacturing process. The result is a production environment that is not only cost-effective but also environmentally responsible, setting a new standard for sustainable industrial practices.

Applications of High Purity Liquid Crystal Materials

Display Device Production

High purity liquid crystal materials are indispensable for the fabrication of high-performance and crystal-clear liquid crystal display (LCD) devices. These materials, meticulously refined through molecular distillation, ensure that the final products meet stringent quality standards necessary for modern electronics. The clarity and precision of LCDs in devices such as smartphones, tablets, and televisions are directly influenced by the purity of the liquid crystal materials used in their production.

Moreover, the use of high purity liquid crystal materials extends beyond mere visual clarity. They contribute to the overall efficiency and durability of display devices, enhancing their performance and longevity. This is particularly critical in today's market, where consumer demand for high-definition and reliable electronic devices is ever-increasing. The superior optical properties provided by these materials also facilitate the development of advanced display technologies, pushing the boundaries of what is possible in the realm of visual electronics.

In summary, the role of high purity liquid crystal materials in display device production is multifaceted, impacting not only the visual quality but also the operational efficiency and overall reliability of the devices they are used in.

Optoelectronics Technology

The integration of high-purity liquid crystal materials into optoelectronic components is a cornerstone of modern technology, particularly in the fabrication of high-precision devices. These materials, refined through advanced molecular distillation processes, play a critical role in enhancing both the performance and stability of optoelectronic devices.

For instance, in the production of displays for smartphones and televisions, the purity of liquid crystal materials directly correlates with the clarity and responsiveness of the display. This is because even minor impurities can cause disruptions in the alignment of liquid crystals, leading to visual artifacts and reduced performance. By leveraging molecular distillation, manufacturers can eliminate these impurities, ensuring that the liquid crystals align perfectly and operate smoothly.

Moreover, the stability of optoelectronic components is significantly improved with the use of high-purity materials. In applications such as optical sensors and lasers, where precision and reliability are paramount, the consistent performance of these components is crucial. High-purity liquid crystal materials provide the necessary uniformity and reliability, ensuring that these devices operate efficiently over extended periods without degradation.

In summary, the meticulous preparation of optoelectronic components using high-purity liquid crystal materials, facilitated by molecular distillation, not only enhances device performance but also ensures long-term stability and reliability. This advancement in material science is pivotal for the continued innovation and improvement of optoelectronic technologies.

Optical Equipment Manufacturing

High purity liquid crystal materials are indispensable in the fabrication of advanced optical devices. These materials offer superior refractive indices and optical properties, which are critical for achieving the high-quality standards required in modern optical equipment. The precise control over these properties ensures that optical devices, such as lenses and prisms, exhibit minimal aberrations and distortion, thereby enhancing overall performance and clarity.

Moreover, the use of high purity liquid crystal materials in optical equipment manufacturing extends beyond just refractive indices. These materials also contribute to improved durability and reliability, which are essential for the long-term performance of optical instruments. The enhanced optical properties translate into better light transmission and reduced scattering, leading to clearer and more accurate images.

In summary, the integration of high purity liquid crystal materials in optical equipment manufacturing is a strategic choice that aligns with the industry's pursuit of superior optical performance and device longevity.

Technological Advancements

Promotion of Liquid Crystal Technology

Molecular distillation equipment plays a pivotal role in the evolution of liquid crystal technology. By refining the purity and quality of liquid crystal materials, this advanced equipment ensures that the end products meet stringent standards necessary for high-performance applications. The enhanced purity not only improves the clarity and efficiency of display devices but also extends to various optoelectronic and optical applications, where precision is paramount.

Moreover, the energy efficiency features of molecular distillation equipment contribute significantly to the sustainability of liquid crystal technology. By effectively recovering and reusing volatile solvents and impurities, the equipment minimizes waste and reduces the overall energy footprint. This not only lowers production costs but also aligns with broader environmental goals, making liquid crystal technology more viable and sustainable for future innovations.

In summary, molecular distillation equipment is instrumental in not only refining liquid crystal materials but also in driving the technological advancements that are essential for the continued development and application of liquid crystal technology in various high-precision industries.

Related Products

- High Temperature Resistant Optical Quartz Glass Sheet

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- Optical Window Glass Substrate Wafer Quartz Plate JGS1 JGS2 JGS3

- Optical Window Glass Substrate Wafer Single Double Sided Coated K9 Quartz Sheet

- Customizable XRD Sample Holders for Diverse Research Applications

Related Articles

- Technological Innovations in the Fused Silica Industry

- Optical Quartz Plate: A Comprehensive Guide to Applications, Specifications, and Usage

- Glassware vs. Plasticware - Which is the Better Choice for Your Needs?

- Comprehensive Guide to Atmosphere Furnaces: Types, Applications, and Benefits

- Understanding Quartz Electrolytic Cells: Applications, Mechanisms, and Advantages