Table of Contents

Introduction to Handheld XRF Analyzers in Mining

Handheld XRF Analyzers are revolutionizing the hardrock mining industry by providing real-time grade control, precise ore analysis, and operational efficiency. This guide will explore their pivotal role in modern mining, focusing on their ability to rapidly and precisely analyze ore samples in various environments. Discover the advanced features, benefits, and applications of Handheld XRF Analyzers, and learn how they are transforming hardrock mining operations.

Key Features of Handheld XRF Analyzers

Handheld XRF analyzers are renowned for their advanced features that enhance their usability and effectiveness in various fields such as mining, exploration, and geoscience. These devices are designed with a compact and ergonomic structure, making them easy to handle and operate in diverse environments, including jewelry stores and outdoor settings.

Ergonomic Design and LED Lighting: The ergonomic design of these analyzers ensures a comfortable grip and easy operation, reducing fatigue during prolonged use. Equipped with LED lighting, these devices facilitate clear visibility and operation even in dimly lit conditions, enhancing their utility in various settings.

Dual CCD Cameras: These analyzers feature built-in dual CCD cameras that enable precise positioning of samples. This feature is particularly useful for detailed analysis, ensuring accurate results and efficient operation.

Optional Accessories: Handheld XRF analyzers offer a range of optional accessories that enhance their functionality. For instance, small spot collimators (3mm, 10mm) are available for analyzing smaller samples with precision. Additionally, external portable printers can be connected to these devices, allowing for immediate printing of analysis results, which is beneficial for on-site reporting and documentation.

Battery Operated and Portable: Designed for mobility, these analyzers are battery-operated, making them ideal for field use where access to power outlets might be limited. Their portability ensures that they can be easily carried to various locations, providing lab-quality results on-site with minimal setup required.

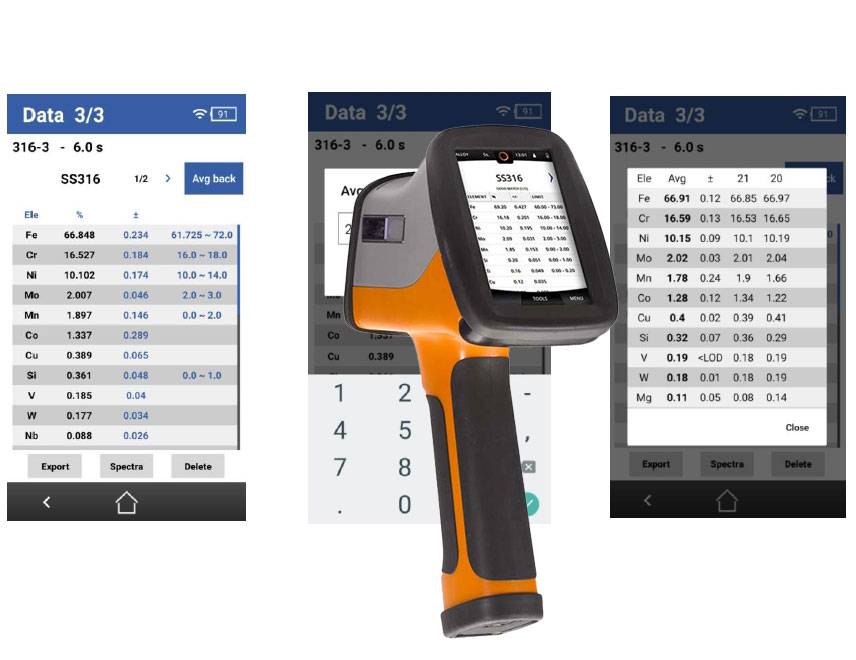

Analytical Precision: These devices are capable of precise determination of the presence and amount of various elements, including trace alloying elements and harmful heavy metals like cadmium, lead, and indium. This capability is crucial for applications that require detailed analysis of metal compositions to assess value and future refining needs.

Advanced Analytical Performance: Handheld XRF analyzers utilize high-performance micro X-ray tubes and intelligent multi-position filters, which are optimized for key elements. This technology enables fast analysis and a wide range of detection, allowing for simultaneous analysis of up to 43 elements with just one-click measurement, eliminating the need for complicated sample preparation.

Innovative Functional Design: The integration of AXRSPEK PC software allows for control of the instrument through WiFi and USB connections, enhancing data management and reporting capabilities. Users can easily view, print, and customize data and reports, adding company logos and other information as needed.

In summary, handheld XRF analyzers are equipped with a suite of advanced features that make them indispensable tools for elemental analysis in various industries. Their ergonomic design, precision, and portability, coupled with optional accessories and advanced analytical capabilities, ensure that they meet the rigorous demands of modern analytical tasks.

Advantages of Using Handheld XRF Analyzers in Mining

Handheld XRF (X-Ray Fluorescence) analyzers have revolutionized the mining industry by providing rapid, accurate, and on-site analysis of ore samples. These devices are crucial for distinguishing between grade, sub-grade, and waste materials, thereby preventing unnecessary disposal and optimizing resource utilization.

Speed and Efficiency: One of the primary advantages of handheld XRF analyzers is their speed. Traditionally, ore samples were sent to laboratories for analysis, a process that could take days. With handheld XRF analyzers, such as the XRF60M, analysis time is reduced from days to mere minutes. This rapid turnaround allows for real-time decision-making in the field, enhancing the efficiency of mining operations. For instance, in hardrock mining, these analyzers enable swift grade control, helping to evaluate the feasibility of lower grade resources and identify localized high-grade enrichments.

User-Friendliness and Mobility: Handheld XRF analyzers are designed to be user-friendly, requiring minimal training to operate. Their portability and ease of use mean that they can be used directly at the mining site, whether in open pits or underground mines. This mobility is particularly beneficial during exploration phases, where the ability to quickly screen vast areas can significantly expedite the discovery process. The XRF60M, for example, is lightweight and mobile, making it an excellent tool for fast screening and geochemical testing.

Accurate Distinction Between Materials: These analyzers are equipped with advanced technology that allows for precise analysis of light elements, crucial for understanding sample mineralogy. This precision is vital for accurately defining the boundaries between ore and waste, enhancing the management of run-of-mine stockpiles, and ensuring consistent blending and mill feed quality. By clearly defining these boundaries, handheld XRF analyzers help in appraising rock cuts and guiding blasting, excavation, and ore handling operations.

Cost Reduction and Sustainability: The use of handheld XRF analyzers can lead to substantial cost reductions in mining operations. By providing on-site analysis, these devices minimize the need to outsource samples to external labs, thereby reducing associated costs and turnaround times. Moreover, their ability to quickly and accurately distinguish between different materials helps in preventing the unnecessary disposal of potentially valuable resources, contributing to more sustainable mining practices.

Enhanced Operational Decisions: With the data provided by handheld XRF analyzers, mining operations can make more informed decisions, such as optimizing drill locations and guiding extraction processes. The analyzers' rapid assays help in determining ore grade, which is critical for maintaining quality control and ensuring that mining efforts are directed towards the most economically viable resources.

In conclusion, handheld XRF analyzers offer a multitude of advantages in the mining industry, from their speed and user-friendliness to their ability to accurately distinguish between materials and enhance sustainability. These devices are not just tools but strategic assets that empower mining operations to maximize efficiency, productivity, and profitability.

Real-Time Grade Control and Operational Decisions

In the realm of hardrock mining, the utilization of Handheld XRF Analyzers is pivotal for real-time grade control and making informed operational decisions. These portable devices offer a rapid and precise method to analyze ore samples directly at the mining site, whether it be in open pits or deep underground mines. The immediate data provided by these analyzers is crucial for overseeing mining processes, ensuring the quality of the ore, and making strategic decisions to optimize operations.

Evaluating Lower Grade Resources and Identifying High-Grade Enrichments

Handheld XRF Analyzers are instrumental in evaluating the feasibility of lower grade resources. By providing immediate chemical composition data, these devices help mining engineers assess whether a particular ore deposit is worth mining. Additionally, they can identify localized areas of high-grade enrichments within a deposit, which can significantly impact the profitability of the mining operation. This capability allows for targeted extraction, maximizing the value of the mined material.

Defining Ore Boundaries

Defining the boundaries between ore and waste is a critical aspect of mining operations. Handheld XRF Analyzers enable miners to clearly delineate these boundaries in real-time. This immediate feedback helps prevent the unnecessary extraction of waste material and ensures that only ore is processed, thereby reducing costs and improving the efficiency of the mining process.

Enhancing Stockpile Management and Mill Feed Quality

Effective stockpile management is essential for maintaining consistent blending and ensuring high-quality mill feed. Handheld XRF Analyzers enhance this process by allowing for the real-time analysis of ore as it is being stockpiled. This ensures that the correct proportions of different ore grades are maintained, which is vital for the efficient operation of the mill and the production of high-quality end products. By facilitating precise blending, these analyzers help maintain the integrity of the mill feed, reducing variability and improving the overall quality of the final product.

In conclusion, Handheld XRF Analyzers play a crucial role in modern mining operations by enabling real-time grade control. Their ability to provide immediate, on-site analysis of ore samples allows for more informed decision-making, improved operational efficiency, and enhanced profitability. These devices are an indispensable tool in the mining industry, ensuring that resources are utilized effectively and that the quality of the mined material meets the highest standards.

Applications in Hardrock Mining

Handheld XRF analyzers play a pivotal role in various aspects of hardrock mining, significantly enhancing operational efficiency and cost reduction. These devices are particularly effective in ore grade control, mineral exploration, and geochemical testing, providing real-time data that is crucial for decision-making in mining operations.

Ore Grade Control

Ore grade control is a critical component of mining operations, ensuring that the extracted materials meet the required specifications for processing and sale. Handheld XRF analyzers enable miners to quickly and accurately assess the elemental composition of ore samples directly at the mining site. This capability allows for immediate classification of materials into grade, sub-grade, and waste, preventing the unnecessary disposal of potentially valuable resources. For instance, the Terra In-line XRF analyzer 700 can be configured to analyze ore on the conveyor belt, significantly improving analysis efficiency and maintaining ore grade consistency. This not only saves on raw material costs but also enhances production efficiency, allowing for rapid recovery of equipment investment.

Mineral Exploration

In the exploration phase, handheld XRF analyzers such as the XRF60M are invaluable tools. Their portability and ease of use enable rapid screening of large areas, crucial for identifying potential mining sites. The XRF60M, for example, requires minimal sample preparation and can analyze ore samples within minutes, compared to the days it might take for lab assay. This speed and accuracy are vital for evaluating the feasibility of lower grade resources and identifying localized high-grade enrichments, which can significantly influence the direction and success of exploration efforts.

Geochemical Testing and Mapping

Geochemical testing and mapping are essential for understanding the distribution and concentration of valuable minerals within a mining site. Handheld XRF analyzers facilitate this by providing on-site, real-time analysis of samples, which can be used to map the geochemical composition of the area. This detailed mapping helps in clearly defining the boundaries between ore and waste, appraising rock cuts, and guiding blasting, excavation, and ore handling operations. The data collected also aids in enhancing the management of run-of-mine stockpiles, ensuring consistent blending and mill feed quality.

Rare Earth Elements Analysis

Rare earth elements (REEs) are critical components in various high-tech industries. Handheld XRF analyzers offer the capability for real-time, on-site assessment of REEs, which is crucial for their extraction and processing. These analyzers can analyze the elemental composition of minerals containing REEs, helping to identify the specific extraction techniques and processing protocols needed for each type of mineral. This capability is particularly important as REEs are seldom found in their pure form and are typically combined with other minerals.

Assessing Industrial Minerals

Accurate measurement of the composition of industrial minerals like limestone and phosphates is vital for maintaining product quality in industries such as cement and fertilizers. Handheld XRF analyzers, such as the AXR series, are increasingly being used for in-quarry exploration and assessing the makeup of raw materials. These devices help in identifying hazardous elements, examining blends, and categorizing raw materials, thereby distinguishing between grade, sub-grade, and waste materials to prevent unnecessary disposal.

In conclusion, handheld XRF analyzers are indispensable tools in hardrock mining, offering significant benefits in terms of efficiency, cost reduction, and environmental sustainability. Their ability to provide rapid, accurate, and on-site analysis makes them a cornerstone of modern mining operations.

Future Trends and Innovations in Handheld XRF Technology

The mining industry is on the cusp of significant advancements in handheld XRF (X-ray Fluorescence) technology, which is set to revolutionize how minerals are analyzed and managed in the field. As the demand for faster, more accurate, and environmentally friendly mining practices grows, the innovations in handheld XRF analyzers are becoming increasingly crucial.

Enhanced Detection Capabilities

One of the most anticipated advancements is the improvement in detection limits and the range of elements that can be analyzed. With the integration of more sophisticated detectors like Silicon Drift Detectors (SDD), handheld XRF analyzers are expected to offer even higher count rates and resolution, enabling them to detect lower concentrations of elements with greater accuracy. This enhancement will be particularly beneficial in identifying rare earth elements and other critical minerals, which are often present in trace amounts.

Real-Time Data Analysis and Connectivity

The future of handheld XRF technology will see a greater emphasis on real-time data analysis and connectivity. Analyzers will be equipped with advanced software that allows for immediate interpretation of data, reducing the need for manual data entry and analysis. Additionally, the integration of wireless technology and cloud-based data storage will enable seamless data transfer between the field and the office, facilitating quicker decision-making processes and enhancing overall operational efficiency.

Increased Automation and User-Friendly Interfaces

Automation is another trend that is set to transform handheld XRF analyzers. The introduction of automated features will streamline the analysis process, making it more efficient and less prone to human error. User-friendly interfaces will also be a key focus, ensuring that even non-technical personnel can operate the equipment with ease, thereby expanding the accessibility and utility of these devices across various levels of mining operations.

Sustainability and Environmental Considerations

As the mining industry continues to prioritize sustainability, handheld XRF technology is expected to evolve in ways that minimize environmental impact. Innovations in energy-efficient X-ray tubes and battery life will reduce the carbon footprint of these devices. Moreover, the ability to conduct on-site analysis will decrease the need for transporting samples to external labs, thereby reducing the associated carbon emissions.

Application Expansion

Handheld XRF analyzers are not only becoming more precise and efficient but are also expanding their applications beyond traditional mining. These devices are increasingly being used in environmental monitoring, waste processing, and metal recovery, showcasing their versatility and potential to contribute to a circular economy.

In conclusion, the future of handheld XRF technology in the mining industry looks promising, with advancements that promise to enhance detection capabilities, improve data analysis and connectivity, increase automation, and promote sustainability. These innovations will not only improve the efficiency and productivity of mining operations but also align with broader environmental and economic goals.

Related Products

Related Articles

- What is xrf analysis and how to making pressed xrf pellets

- How To Turn XRF analysis sample preparation Into Success

- How to Choose the Right XRF Pellet Press for Your Needs

- XRF Pelletising for Solid Samples Tips and Tricks

- Techniques for Sample Preparation in X-Ray Fluorescence Analysis: Pressed and Loose Powder Methods