Introduction to Cold Traps

Definition and Function

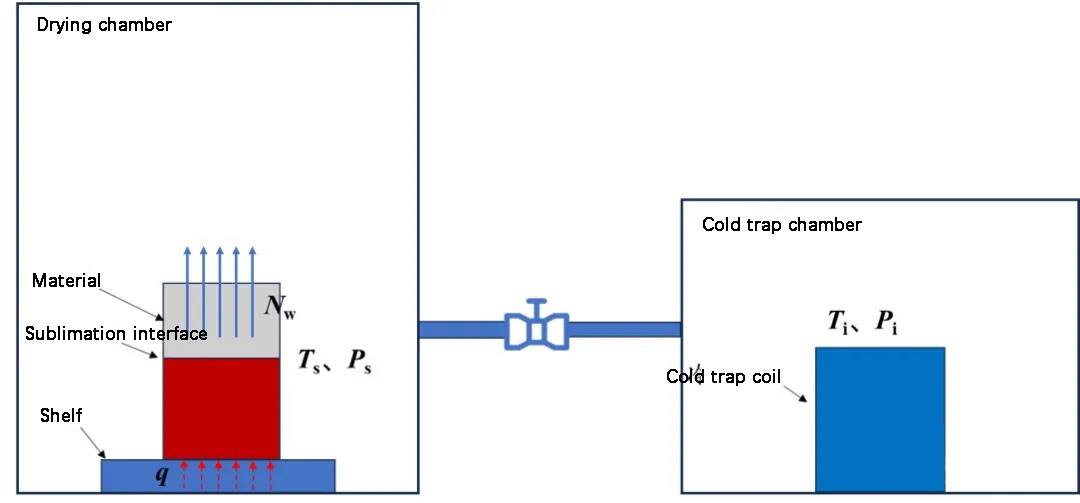

A cold trap is an essential component within a lyophilizer, designed to intercept and capture sublimation gases. This is achieved through the process of condensing molecules onto its low-temperature surface. By doing so, the cold trap effectively prevents these gases from re-entering the system, thereby maintaining the integrity of the lyophilization process.

The primary function of a cold trap is to act as a barrier, ensuring that the gas molecules generated during the sublimation phase are not merely pumped away but are instead captured and condensed. This not only aids in the efficient drying of the sample but also protects the lab vacuum pump from potential damage caused by the accumulation of moisture.

In essence, the cold trap serves as a critical intermediary, bridging the gap between the high-vacuum environment required for lyophilization and the need to manage the byproducts of this process. Its role is pivotal in ensuring that the lyophilization cycle proceeds smoothly and efficiently, contributing to the overall quality and longevity of the equipment.

Role in Lyophilization

Cold traps are indispensable components in the lyophilization process, primarily tasked with capturing moisture and sublimation gases. Their function is pivotal in ensuring that gas molecules emanating from the sublimation interface are effectively trapped, thereby facilitating the drying process. This critical role is underscored by the necessity of maintaining a high vacuum environment, where the density of sublimation gas is significantly reduced, making it impractical to rely solely on vacuum pumps for gas collection.

In high vacuum conditions, the efficiency of cold traps is paramount. They serve as the primary collectors of sublimation gases, condensing these molecules on their low-temperature surfaces. This condensation process not only aids in maintaining the vacuum but also prevents the re-deposition of moisture onto the dried product, ensuring the integrity and quality of the final product. The effectiveness of a cold trap is thus directly linked to its ability to capture and retain water molecules, which in turn impacts the longevity of the vacuum pump and the overall efficiency of the lyophilization cycle.

Moreover, the performance of cold traps extends beyond mere temperature control. Factors such as refrigerant flow, frost formation, and the organization of airflow within the cold trap also play crucial roles in determining its efficiency. Current evaluation methods, which often focus solely on cold trap temperature, are insufficient to capture the full spectrum of performance indicators. Instead, the actual amount of water captured by the cold trap serves as a more reliable metric, providing a comprehensive understanding of its effectiveness in the lyophilization process.

In summary, the role of cold traps in lyophilization is multifaceted, encompassing not only the capture of moisture but also the maintenance of a high vacuum environment and the prevention of moisture re-deposition. Their efficient operation is essential for achieving optimal drying conditions and ensuring the longevity of the lyophilization equipment.

Why Use a Cold Trap

High Vacuum Considerations

In high vacuum (HV), ultra-high vacuum (UHV), and extreme high vacuum (XHV) conditions, the density of sublimation gas is significantly reduced, rendering traditional pumping methods inefficient. Cold traps become indispensable in such scenarios, as they are designed to efficiently collect and condense the sublimation gas molecules on their low-temperature surfaces. This process not only aids in maintaining the vacuum integrity but also prevents the gas from re-entering the system, thereby enhancing the overall efficiency of the lyophilization process.

Several critical factors must be considered when designing systems to operate under these extreme vacuum conditions. These include:

- Material Selection: Employing materials with low desorption and outgassing rates is crucial to minimize gas release from the system's internal surfaces. Suitable pre-treatments, such as electro-polishing, can further reduce these rates.

- Chamber Design: Minimizing the internal surface area of the chamber and ensuring there are no internal gaps or trapped volumes (like tapped blind holes) can significantly improve vacuum performance.

- Welding and Sealing: Welding should be performed from the inside to avoid introducing contaminants, and the use of metallic seals can reduce the number of necessary seals, thereby decreasing the likelihood of leaks.

- Pre-Treatment: Heating the system to high temperatures (baking) and thorough cleaning to remove contaminants are essential pre-treatment steps that help achieve and maintain the required vacuum levels.

By addressing these considerations, the efficiency of cold traps in high vacuum environments can be maximized, ensuring optimal performance and longevity of the lyophilization equipment.

Evaluating Cold Trap Performance

Limitations of Current Methods

Current evaluation methods, which primarily focus on the temperature of the cold trap, are inadequate for assessing the overall performance of these devices. While temperature is indeed a critical parameter, it is not the sole determinant of efficiency. Several other factors significantly influence the effectiveness of cold traps in lyophilizers.

Firstly, the flow of refrigerant through the cold trap plays a pivotal role. An optimal refrigerant flow ensures that the cold trap maintains a consistent and effective temperature for capturing sublimation gases. Any deviation from this optimal flow can lead to subpar performance, reducing the cold trap's ability to efficiently capture moisture.

Secondly, the formation of frost within the cold trap is another crucial factor. The manner in which frost forms and accumulates can either enhance or hinder the cold trap's functionality. Proper management of frost formation ensures that the cold trap remains unobstructed, allowing for continuous and efficient gas capture. Conversely, excessive or uneven frost can block pathways, thereby diminishing the cold trap's effectiveness.

Lastly, the organization of airflow within the lyophilizer system cannot be overlooked. The direction and uniformity of airflow can impact the distribution of sublimation gases, affecting how well they are captured by the cold trap. A well-organized airflow ensures that gases are directed towards the cold trap, maximizing its efficiency.

In summary, evaluating cold traps solely based on temperature is insufficient. A comprehensive assessment must also consider refrigerant flow, frost formation, and airflow organization to ensure optimal performance and longevity of the lyophilization process.

Using Water Capture as an Indicator

The actual amount of water captured by the cold trap serves as a more reliable indicator of its effectiveness, ensuring the longevity of the vacuum pump and enhancing overall lyophilization efficiency. This metric goes beyond mere temperature readings, providing a tangible measure of the cold trap's performance.

Water capture efficiency is crucial because it directly impacts the vacuum pump's lifespan. By effectively trapping water molecules, the cold trap prevents them from entering the vacuum pump, thereby reducing wear and tear. This not only extends the pump's operational life but also minimizes maintenance costs and downtime.

Moreover, a high water capture rate signifies that the cold trap is functioning optimally, which is essential for maintaining the integrity of the lyophilization process. Efficient water capture ensures that the sublimation interface remains clear, allowing for continuous and effective drying. This, in turn, leads to better product quality and consistency.

In summary, focusing on water capture as an indicator offers a comprehensive understanding of the cold trap's performance, contributing to both equipment longevity and improved lyophilization outcomes.

Common Misconceptions

Cold Traps and Sample Freezing

Cold traps are specifically engineered to capture sublimation gases rather than to freeze samples. While their primary function is to condense and trap vapors, their impact on sample temperature can vary significantly depending on the design and operational parameters of the lyophilizer.

In the context of lyophilization, the cold trap serves as the coldest point within the system, naturally attracting vapors that migrate towards this low-temperature zone. Here, these vapors freeze and are subsequently trapped, preventing them from re-entering the vacuum tubing or reaching the vacuum pump. This process not only enhances the overall efficiency of the lyophilization cycle but also safeguards the integrity of the vacuum system by minimizing the risk of vapor contamination.

When selecting a cold trap, it is crucial to consider the specific characteristics of the samples being processed. For instance, water samples can be effectively trapped at -50°C, similar to the efficiency observed at -105°C. However, for mixtures containing components with varying freezing points, it is advisable to match the cold trap's temperature to the component with the lowest freezing point to ensure optimal trapping efficiency. This approach helps in preventing any residual vapors from escaping into the environment or the vacuum pump, thereby maintaining the purity and effectiveness of the lyophilization process.

Cold Trap Temperature for Organic Solvents

When selecting a cold trap for organic solvents, it is crucial to consider the freezing points of the solvents involved. Extremely low temperatures, such as those below -90°C, are generally unnecessary for effective trapping. This is because most organic solvents can be efficiently captured at temperatures significantly higher than their freezing points.

For instance, methylene chloride, which has a freezing point of -96.7°C, demonstrates significant differences in capture efficiency based on the cold trap temperature. A -50°C cold trap collected only 43.3% of the methylene chloride, whereas a -105°C cold trap captured 87.7% of the initial volume. This example underscores the importance of matching the cold trap temperature to the solvent's freezing point for optimal results.

| Cold Trap Temperature | Methylene Chloride Capture Efficiency |

|---|---|

| -50°C | 43.3% |

| -105°C | 87.7% |

In summary, while lower temperatures can enhance trapping efficiency, there is a point of diminishing returns. Selecting a cold trap temperature that closely matches the solvent's freezing point ensures both efficiency and practicality, preventing unnecessary energy consumption and equipment stress.

Conclusion

Importance of Comprehensive Evaluation

Evaluating cold traps based on multiple factors, including water capture efficiency, ensures better lyophilization outcomes and equipment longevity. This comprehensive approach goes beyond mere temperature measurements to encompass a range of critical parameters such as refrigerant flow, frost formation, and airflow organization. By considering these elements, one can more accurately gauge the effectiveness of a cold trap, thereby optimizing the entire lyophilization process.

For instance, while water capture efficiency is a pivotal metric, it is not the sole determinant of performance. The rate at which the refrigerant flows through the cold trap can significantly impact its ability to condense sublimation gases. Similarly, the formation of frost on the cold trap's surface can impede its efficiency if not managed properly. Additionally, the organization of airflow within the lyophilizer can either enhance or diminish the cold trap's effectiveness.

By integrating these diverse factors into the evaluation process, one can achieve a more holistic understanding of a cold trap's performance. This, in turn, leads to more reliable and consistent lyophilization outcomes, extending the lifespan of both the cold trap and the entire lyophilization equipment. Ultimately, a comprehensive evaluation ensures that all components of the lyophilization process work in harmony, maximizing efficiency and minimizing potential failures.

Related Products

- Vacuum Cold Trap Chiller Indirect Cold Trap Chiller

- Vacuum Cold Trap Direct Cold Trap Chiller

- 100L Chilling Circulator Cooling Water Circulator for Low Temperature Constant Temperature Reaction Bath Water Bath Cooling

- lab cryogenic grinding use liquid-nitrogen for pulverizing plastic raw materials and heat sensitive materials

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press