Yes, sterilization without an autoclave is not only possible but necessary for specific materials and situations. While an autoclave, which uses pressurized steam, is the gold standard for many applications, its reliance on high heat and moisture makes it unsuitable for certain items. Alternative methods like dry heat, chemical sterilization, and filtration are widely used when autoclaving is not an option.

The core principle of sterilization is the complete elimination of all microbial life. An autoclave achieves this with pressurized steam, but this is just one tool. The correct sterilization technique is always determined by the material's composition and its tolerance for heat, moisture, and pressure.

Why an Autoclave Isn't a Universal Solution

To understand the alternatives, we must first understand the autoclave's specific function and its inherent limitations.

The Principle of Autoclaving

An autoclave is a pressure chamber that uses steam heated to high temperatures (typically 121°C / 250°F) to kill microorganisms.

It is not the pressure itself but the high temperature of the saturated steam that denatures the proteins and enzymes essential for microbial life. This method is incredibly effective and relatively fast for items that can withstand these conditions.

When Autoclaving is the Wrong Choice

The very properties that make autoclaving effective—high heat and moisture—also create limitations. You cannot autoclave:

- Water-Resistant Materials: Items like oils, powders, or waxes cannot be sterilized by steam because the moisture cannot penetrate them effectively.

- Heat-Sensitive Materials: Many plastics and electronics would melt or be destroyed by the high temperatures inside an autoclave.

- Corrosive or Reactive Materials: Substances like bleach and other solvents can release toxic fumes or damage the autoclave chamber itself.

- Sharp Instruments: The high moisture and temperature can cause corrosion and dull the fine edges of certain sharp metal instruments over time.

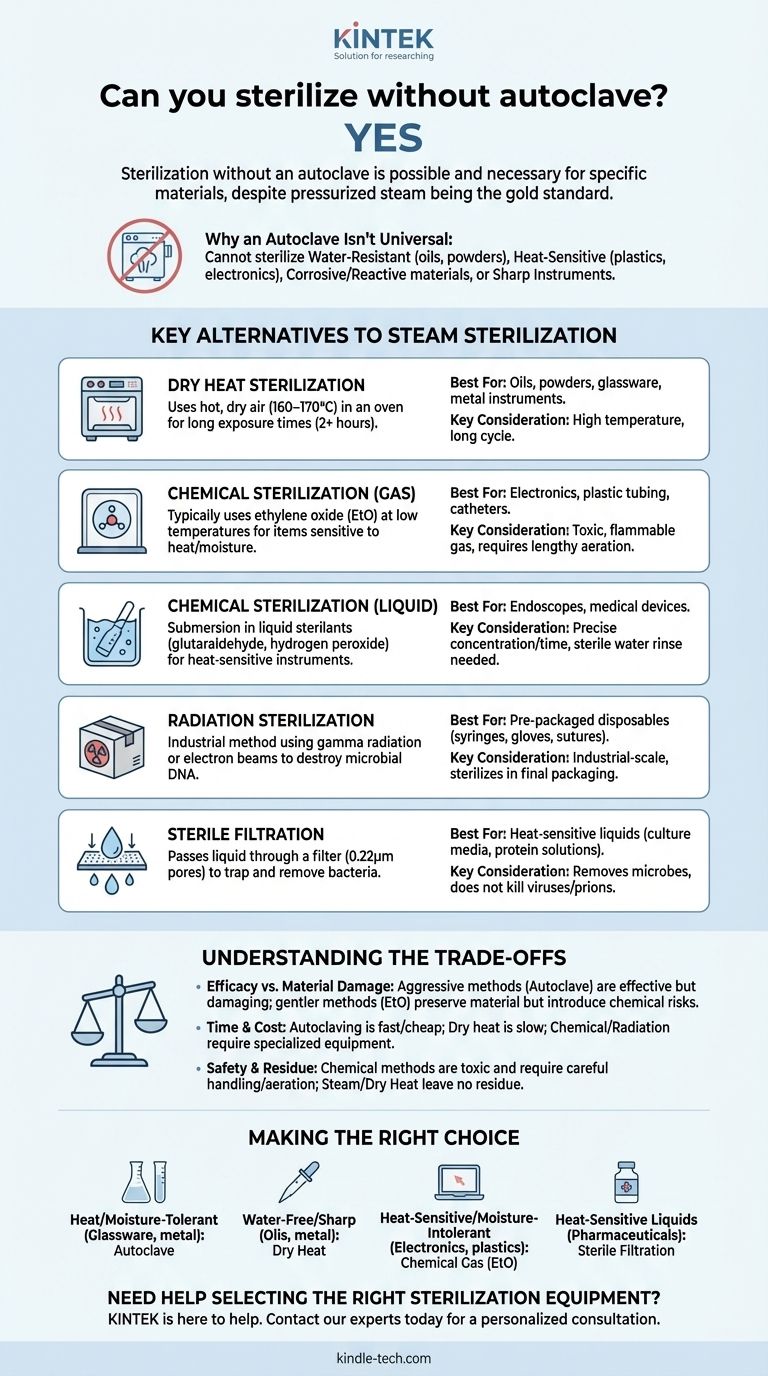

Key Alternatives to Steam Sterilization

When an autoclave is unsuitable, one of the following methods is typically employed, each with a specific purpose.

Dry Heat Sterilization

This method uses an oven to circulate hot, dry air. Because dry heat is less efficient at transferring energy than moist heat, it requires higher temperatures (160-170°C) and much longer exposure times (2 hours or more).

Dry heat is the preferred method for sterilizing anhydrous (water-free) materials like oils, powders, and certain glassware or metal instruments.

Chemical Sterilization (Gas)

For items that are sensitive to both heat and moisture, such as electronic devices, plastic tubing, and catheters, gas sterilization is the standard.

The most common gas used is ethylene oxide (EtO). It effectively sterilizes at low temperatures but is highly toxic and flammable, requiring a lengthy aeration process after the cycle to remove residual gas.

Chemical Sterilization (Liquid)

Items can be submerged in a liquid sterilant, such as solutions containing glutaraldehyde, hydrogen peroxide, or peracetic acid.

This method is often used for heat-sensitive medical instruments like endoscopes. It requires careful adherence to concentration levels and submersion times, and items must be rinsed with sterile water afterward.

Radiation Sterilization

This is an industrial-scale method used for pre-packaged, disposable medical supplies like syringes, gloves, and sutures.

Items are exposed to gamma radiation or electron beams, which destroy microbial DNA. It is highly effective and allows items to be sterilized directly in their final sealed packaging.

Sterile Filtration

This technique is used for heat-sensitive liquids, such as cell culture media, protein solutions, or pharmaceuticals.

The liquid is passed through a filter with pores small enough (typically 0.22 micrometers) to trap and remove all bacteria. It's important to note that this method removes microbes rather than killing them and does not eliminate smaller entities like viruses or prions.

Understanding the Trade-offs

Choosing a sterilization method involves balancing efficacy with material compatibility. There is no single "best" method, only the most appropriate one for the task.

Efficacy vs. Material Damage

The most aggressive methods, like autoclaving, offer the highest assurance of sterility but are also the most damaging to sensitive materials. Gentler methods, like EtO gas, preserve material integrity but introduce chemical safety concerns.

Time and Cost

Autoclaving is relatively fast and inexpensive to operate. Dry heat cycles are significantly longer. Chemical and radiation sterilization require specialized, expensive equipment and stringent safety protocols, making them more suitable for industrial or high-throughput clinical settings.

Safety and Residue

Liquid and gas chemical sterilants are toxic and require careful handling, ventilation, and, in the case of EtO, a post-cycle aeration period to ensure no harmful residues remain. Steam and dry heat, by contrast, leave no toxic residue.

Making the Right Choice for Your Material

Your decision must be guided by the nature of the object you need to sterilize.

- If your primary focus is heat-stable, moisture-tolerant items (e.g., most glassware, metal tools, microbiological media): The autoclave is the most efficient and reliable method.

- If your primary focus is water-free materials (e.g., oils, powders) or metal instruments prone to corrosion: Dry heat sterilization is the correct choice.

- If your primary focus is heat-sensitive items that cannot tolerate moisture (e.g., electronics, plastics): Chemical gas sterilization (like ethylene oxide) is the industry standard.

- If your primary focus is heat-sensitive liquids (e.g., pharmaceuticals, protein solutions): Sterile filtration is the only method that will preserve the liquid's chemical integrity.

Ultimately, effective sterilization is achieved by matching the method to the material, not by defaulting to a single piece of equipment.

Summary Table:

| Sterilization Method | Best For | Key Consideration |

|---|---|---|

| Dry Heat | Oils, powders, sharp metal instruments | High temperatures (160-170°C), long cycle times (2+ hours) |

| Chemical (Gas - EtO) | Electronics, plastics, catheters | Toxic gas requires lengthy aeration; no heat/moisture damage |

| Chemical (Liquid) | Heat-sensitive instruments (e.g., endoscopes) | Requires precise submersion time and sterile water rinse |

| Radiation | Pre-packaged disposables (syringes, gloves) | Industrial-scale; sterilizes in final packaging |

| Sterile Filtration | Heat-sensitive liquids (media, pharmaceuticals) | Removes bacteria but not viruses; pores typically 0.22µm |

Need Help Selecting the Right Sterilization Equipment?

Choosing the correct sterilization method is critical for both the efficacy of your process and the integrity of your materials. The wrong choice can lead to damaged equipment, compromised samples, or incomplete sterilization.

KINTEK is here to help. We specialize in lab equipment and consumables, serving diverse laboratory needs. Our experts can guide you to the ideal solution—whether you require a robust dry heat oven, specialized chemical sterilization equipment, or sterile filtration systems.

Let us help you ensure sterility without compromising your materials.

Contact our experts today for a personalized consultation to discuss your specific application and find the perfect equipment for your lab.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

People Also Ask

- How long does 134 degree sterilization take? Ensure Proper Sterilization Cycle Times

- What is the function of a stainless steel high-pressure autoclave with a PTFE liner? Enhance CoO Synthesis Purity

- What are the primary advantages of using an autoclave molding process? Unlock Elite Performance for Composites

- Why is a high-pressure hydrothermal autoclave core for g-C3N4/CeO2? Achieve Powerful Heterojunction Synthesis

- What is the purpose of treating polyester fabric in an autoclave? Ensure Reliable Results in Lab Experiments

- What is the purpose of inserting armored thermocouples into an autoclave? Precision in Ammonothermal Process

- What is the function of an autoclave in preparing SRB culture media? Ensuring Sterility for Accurate Microbial Data

- What does an autoclave do in a microbiology laboratory? Ensuring Sterility and Safety for Your Research