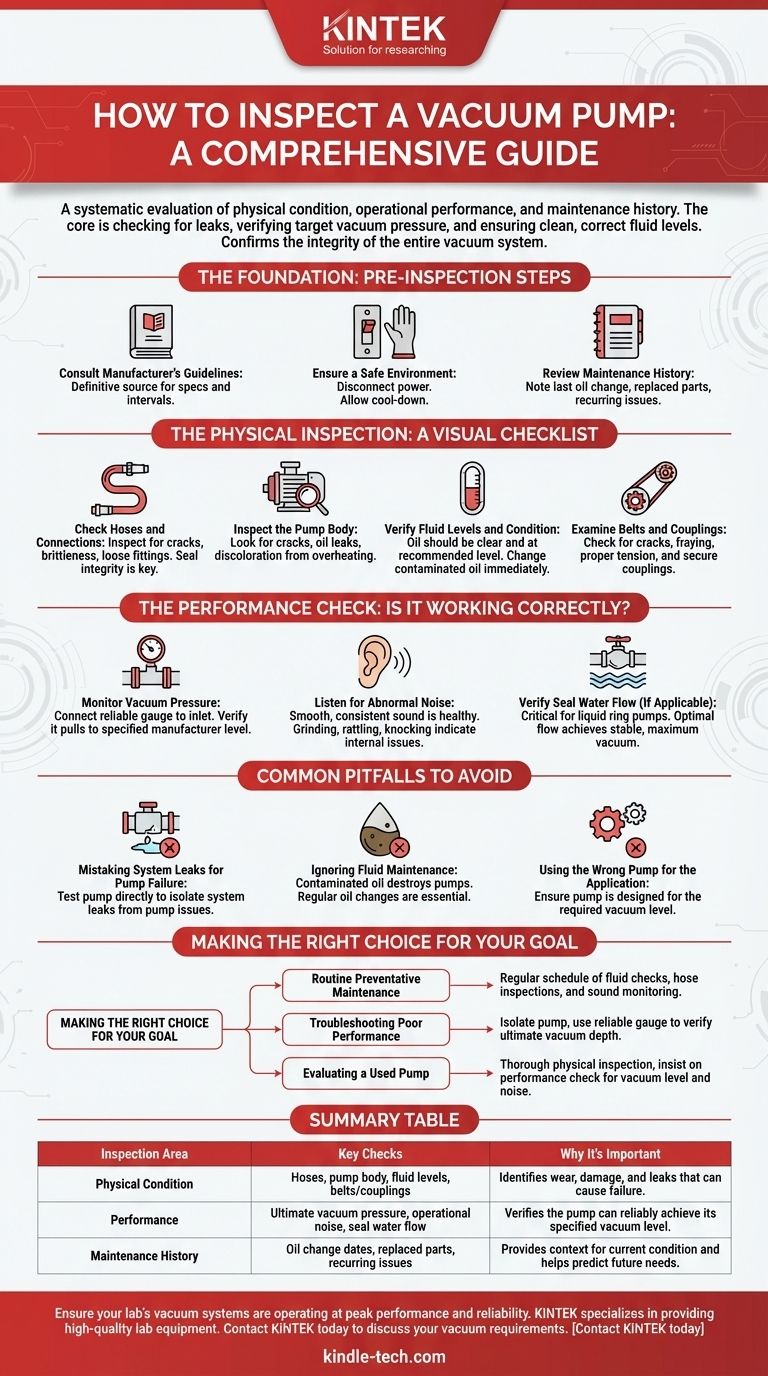

To properly inspect a vacuum pump, you must perform a systematic evaluation of its physical condition, its operational performance, and its maintenance history. The core of an inspection involves checking all connections for leaks, verifying that the pump can achieve and hold its target vacuum pressure, and ensuring that essential fluids like oil or seal water are clean and at the correct levels.

A thorough vacuum pump inspection is not just a visual check; it is a diagnostic process designed to confirm the integrity of the entire vacuum system. It answers one fundamental question: can the pump reliably and efficiently create the vacuum required for your application?

The Foundation: Pre-Inspection Steps

Before you begin the physical or operational checks, a proper inspection starts with preparation. This foundational work ensures the inspection is both safe and effective.

Consult the Manufacturer's Guidelines

Every pump is different. The manufacturer's manual is the definitive source for specific maintenance intervals, recommended fluid types, and operational specifications. Always start here.

Ensure a Safe Environment

Disconnect the pump from its power source before conducting any physical inspection. If checking fluids, ensure the pump has had time to cool down to prevent burns.

Review Maintenance History

If available, look at the pump's maintenance logs. Note the date of the last oil change, any parts that were recently replaced, and any recurring issues. This history provides critical context for what you might find.

The Physical Inspection: A Visual Checklist

This phase involves a hands-on examination of the pump and its immediate connections. It is designed to catch signs of wear, damage, and potential leaks before they cause a failure.

Check Hoses and Connections

The most common source of vacuum "failure" is not the pump itself, but a leak in the system. Carefully inspect all hoses, tubing, and fittings for cracks, brittleness, or loose connections. A tight seal is paramount.

Inspect the Pump Body

Look for any signs of physical damage, such as cracks in the housing. Check for oil leaks around seals and gaskets, which often indicate a failing component. Discoloration on the housing can be a sign of overheating.

Verify Fluid Levels and Condition

For oil-sealed pumps, check the oil level through the sight glass. The oil should be clear and at the recommended level. Milky, dark, or foamy oil is contaminated and must be changed immediately, as it severely degrades performance.

Examine Belts and Couplings

If the pump is belt-driven, inspect the belt for cracks, fraying, and proper tension. For direct-drive pumps, ensure the coupling between the motor and pump is secure and in good condition.

The Performance Check: Is It Working Correctly?

A pump that looks good is not necessarily a pump that works well. A performance check verifies its ability to do its job.

Monitor Vacuum Pressure

Connect a reliable vacuum gauge directly to the pump's inlet, isolating it from the rest of the system. Turn on the pump and let it warm up. It should be able to pull a vacuum down to the level specified by the manufacturer. This is the single most important performance test.

Listen for Abnormal Noise

A healthy pump has a consistent, smooth operational sound. Listen for any grinding, rattling, or excessive knocking. These sounds often point to worn bearings, debris inside the pump, or other internal mechanical problems.

Verify Seal Water Flow (If Applicable)

For liquid ring vacuum pumps, the flow of seal water is critical. Too little water will cause the vacuum level to fluctuate and drop, while too much wastes energy. The optimal flow is the minimum amount required to achieve a stable, maximum vacuum.

Common Pitfalls to Avoid

Inspections can be misleading if you're not aware of common mistakes. Understanding these pitfalls ensures your diagnosis is accurate.

Mistaking System Leaks for Pump Failure

Never assume poor vacuum is the pump's fault. A tiny leak in a hose or fitting anywhere in the system will prevent the pump from reaching its target vacuum. Always test the pump directly before concluding it has failed.

Ignoring Fluid Maintenance

Running a pump with contaminated oil is the fastest way to destroy it. Contaminants prevent the pump from reaching a deep vacuum and cause premature wear on all internal components. Regular oil changes are not optional; they are essential.

Using the Wrong Pump for the Application

A pump may "fail" an inspection simply because it is being asked to do a job it wasn't designed for. A pump intended for rough vacuum (hundreds of Torr) will never achieve the high vacuum needed for other applications, no matter how well it is maintained.

Making the Right Choice for Your Goal

Your inspection approach should be guided by your ultimate objective.

- If your primary focus is routine preventative maintenance: Focus on a regular schedule of checking fluid levels and condition, inspecting hoses for wear, and listening for changes in operational sound.

- If your primary focus is troubleshooting poor performance: Isolate the pump from the system and use a reliable gauge to verify its ultimate vacuum depth. This definitively separates pump issues from system leaks.

- If your primary focus is evaluating a used pump: Conduct a thorough physical inspection for damage and insist on a performance check to confirm it can reach its specified vacuum level without excessive noise or vibration.

A consistent inspection routine transforms maintenance from a reaction to a strategy, ensuring your vacuum system operates with reliability and precision.

Summary Table:

| Inspection Area | Key Checks | Why It's Important |

|---|---|---|

| Physical Condition | Hoses, pump body, fluid levels, belts/couplings | Identifies wear, damage, and leaks that can cause failure. |

| Performance | Ultimate vacuum pressure, operational noise, seal water flow | Verifies the pump can reliably achieve its specified vacuum level. |

| Maintenance History | Oil change dates, replaced parts, recurring issues | Provides context for current condition and helps predict future needs. |

Ensure your lab's vacuum systems are operating at peak performance and reliability. A properly maintained vacuum pump is critical for the success and repeatability of your experiments and processes. KINTEK specializes in providing high-quality lab equipment, including vacuum pumps and consumables, to meet the precise needs of your laboratory. Our experts can help you select the right pump for your application and provide guidance on maintenance best practices. Contact KINTEK today to discuss your vacuum requirements and keep your lab running smoothly.

Visual Guide

Related Products

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Variable Speed Peristaltic Pump

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

People Also Ask

- What is the difference between crystalline and fused quartz? A Guide to Atomic Structure and Material Properties

- What are the uses of quartz glass tube? Key Applications in High-Temperature and High-Purity Processes

- Why are Viton O-rings considered essential consumables for the high-temperature sealing interfaces of microreactors?

- What materials are used in a refractory kiln? A Guide to High-Temperature Linings

- What is the strength of a quartz tube? Withstand 1,000 PSI in High-Temp, High-Purity Applications

- Why are zirconia grinding jars and balls necessary for sulfide solid electrolytes? Essential for Purity & Performance

- How does the vacuum pump system influence siloxane thin film quality? Mastering Purity and Density in Fabrication

- What is the lining material for furnace? A Guide to High-Temperature Refractories