Generating a plasma for sputtering is a process of controlled electrical breakdown within a gas. It is achieved by applying a high voltage between a cathode (which holds the material to be sputtered) and an anode within a low-pressure chamber. This electric field accelerates free electrons, which collide with and ionize inert gas atoms (typically argon), creating a self-sustaining glow discharge composed of ions and electrons—the plasma.

The core principle is simple: use a high voltage to ionize a gas. However, the key to modern, efficient sputtering is using magnetic fields to trap electrons near the target, dramatically increasing the plasma's density and the rate of deposition.

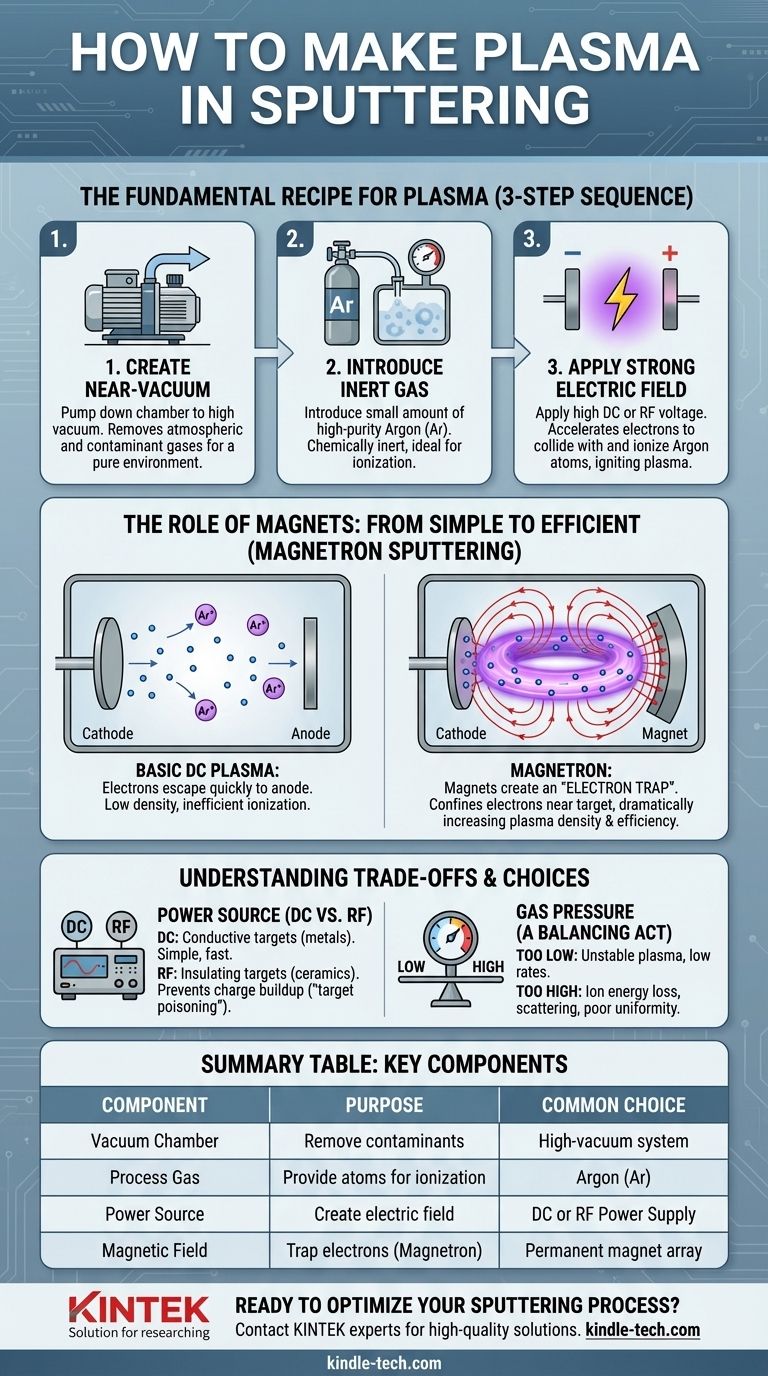

The Fundamental Recipe for Plasma

Creating a stable and effective plasma for sputtering involves a precise, three-step sequence. Each step is critical for establishing the conditions needed for ion bombardment.

Step 1: Create a Near-Vacuum Environment

Before plasma can be generated, the sputtering chamber is pumped down to a high vacuum. This removes atmospheric and other contaminant gases.

A clean environment ensures that the subsequent plasma is composed almost entirely of the intended process gas, preventing unwanted chemical reactions and impurities in the deposited film.

Step 2: Introduce an Inert Gas

Once a vacuum is established, a small, controlled amount of a high-purity inert gas is introduced. Argon (Ar) is the most common choice.

Argon is used because it is chemically inert, has a relatively high atomic mass for effective sputtering, and is cost-effective. These gas atoms are the raw material that will be ionized to form the plasma.

Step 3: Apply a Strong Electric Field

A high DC or RF voltage is applied between two electrodes. The cathode is negatively charged and holds the target material, while the anode is grounded and typically includes the chamber walls and the substrate holder.

This voltage creates a powerful electric field that accelerates the few free electrons naturally present in the gas. These energized electrons collide with neutral argon atoms, knocking an electron off and creating a positively charged argon ion (Ar+) and another free electron. This process cascades, quickly igniting and sustaining the plasma.

From Simple Plasma to Efficient Sputtering: The Role of Magnets

A basic plasma will work, but it is not very efficient. Modern systems, known as magnetron sputtering systems, use magnets to dramatically improve the process.

The Problem with Basic DC Plasma

In a simple plasma, electrons are rapidly drawn to the positive anode. Many of them travel across the chamber without ever colliding with an argon atom.

This results in a low-density plasma and an inefficient sputtering process, as a large amount of electrical energy is wasted without creating the positive ions needed for bombarding the target.

How Magnets Create an "Electron Trap"

In magnetron sputtering, a powerful permanent magnet assembly is placed behind the cathode target. This projects a magnetic field out in front of the target surface.

This magnetic field forces the highly mobile electrons into a confined, looping (or helical) path near the target. Instead of escaping directly to the anode, they are trapped in this magnetic "racetrack."

The Result: A Denser, More Intense Plasma

By trapping the electrons, their path length near the target is increased by orders of magnitude. This drastically increases the probability that an electron will collide with and ionize an argon atom.

This superior ionization efficiency creates a much denser, more intense plasma precisely where it is needed—directly in front of the target—leading to far higher sputtering rates and a more stable process.

Understanding the Trade-offs

The method of plasma generation has direct consequences for the types of materials you can deposit and the overall efficiency of the process.

DC vs. RF Power

Direct Current (DC) sputtering uses a constant negative voltage on the cathode. It is simple, fast, and highly effective for conductive target materials like metals.

Radio Frequency (RF) sputtering uses an alternating electric field. It is essential for sputtering electrically insulating (dielectric) materials like oxides and nitrides. A DC voltage would cause a positive charge to build up on the insulating target surface, eventually neutralizing the electric field and extinguishing the plasma. RF power avoids this "target poisoning."

Gas Pressure: A Balancing Act

The pressure of the sputtering gas is a critical parameter. If the pressure is too low, there are not enough gas atoms to sustain a stable plasma, leading to low sputtering rates.

If the pressure is too high, the ions will collide with other gas atoms on their way to the target. This reduces their energy, lowering the sputtering yield and potentially scattering the sputtered material, which affects film uniformity.

Making the Right Choice for Your Goal

The correct plasma configuration depends entirely on the material you are depositing and your performance requirements.

- If your primary focus is depositing a conductive material (like a metal): DC magnetron sputtering is the industry standard, offering a robust combination of high deposition rates and process simplicity.

- If your primary focus is depositing an insulating material (like a ceramic or oxide): RF magnetron sputtering is required to prevent charge accumulation on the target surface and maintain a stable plasma.

- If your primary focus is process efficiency: The use of magnetron confinement is non-negotiable, as it is the key to creating a dense plasma and achieving practical deposition rates.

By mastering these principles of plasma generation and confinement, you gain direct control over the quality and efficiency of your thin-film deposition process.

Summary Table:

| Key Component | Purpose | Common Choice |

|---|---|---|

| Vacuum Chamber | Removes contaminants for a pure process environment | High-vacuum system |

| Process Gas | Provides atoms to be ionized into plasma | Argon (Ar) |

| Power Source | Creates electric field to accelerate electrons and ionize gas | DC or RF Power Supply |

| Magnetic Field | Traps electrons to increase plasma density (Magnetron Sputtering) | Permanent magnet array behind target |

Ready to Optimize Your Sputtering Process?

Whether you are depositing conductive metals with DC power or insulating ceramics with RF power, KINTEK's expertise in lab equipment and consumables ensures you have the right tools for efficient, high-quality thin-film deposition. Our sputtering solutions are designed to deliver precise control over plasma density and deposition rates.

Contact our experts today to discuss how we can help you achieve superior results in your laboratory.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is a thin film semiconductor? Unlock Flexible, Large-Area Electronics

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- Can carbon nanotubes replace silicon? The Future of Computing Beyond Moore's Law

- What is the significance of sputtering? Achieve Superior Thin Films for High-Tech Manufacturing

- What materials are used in thin films? A Guide to Metals, Ceramics, and Polymers for Functional Layers

- What materials are used in CVD? A Guide to Precursors, Substrates, and Deposited Films

- What is planar magnetron sputtering? A High-Speed, Low-Temperature Thin-Film Coating Process

- How thick is the thin film color? Unlocking the Nanometer Scale of Iridescent Effects