At its core, removing heat from a bioreactor is achieved by passing a cold fluid through a system that is in thermal contact with the cell culture. The three primary methods for this are circulating coolant through a jacket built around the vessel, using internal coils submerged in the culture, or pumping the culture through an external heat exchanger. The choice depends entirely on the scale of the process and the sensitivity of the cells.

The central challenge of bioreactor cooling isn't just removing heat, but doing so without compromising the process. As bioreactors get larger, their ability to shed heat naturally decreases, forcing engineers to choose between increasingly invasive methods that can introduce new risks like shear stress or contamination.

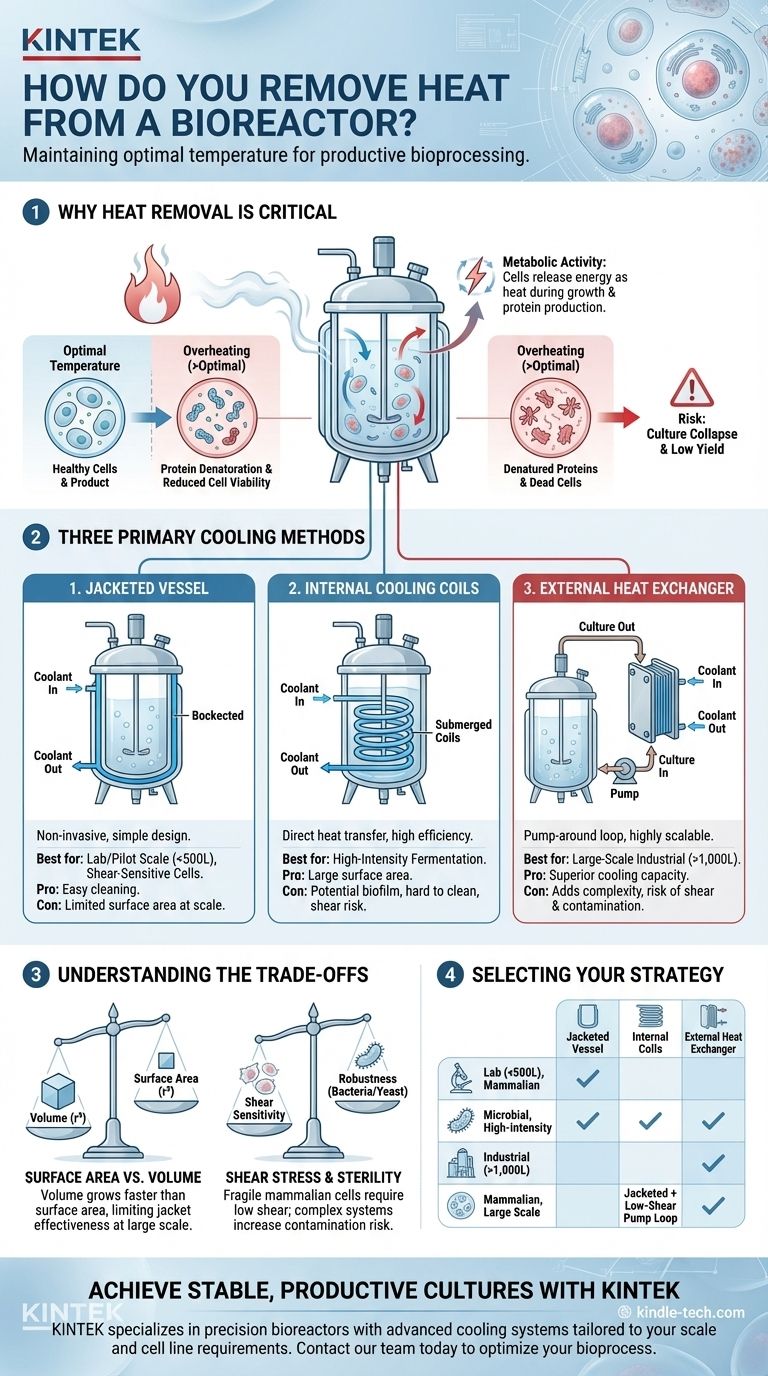

Why Heat Removal is Critical in Bioprocessing

Understanding the source and impact of heat is the first step toward effective temperature control. A hot bioreactor is often a sign of a highly active, productive culture, but this productivity will collapse if the temperature is not managed.

The Source of Heat: Metabolic Activity

All living organisms, from microscopic bacteria to mammalian cells, release energy as heat during their metabolic processes like growth and protein production.

In a high-density cell culture, the cumulative heat generated by billions of cells can be immense, rapidly raising the temperature of the culture medium far beyond the optimal range.

The Consequences of Overheating

Every cell line has a narrow optimal temperature window. Exceeding this temperature, even for a short period, can have severe consequences.

Excess heat causes enzymes and other critical proteins to denature, or lose their shape, halting their function. This leads to reduced cell viability, lower product yields, the creation of undesirable byproducts, and in the worst case, a complete collapse of the culture.

Primary Methods for Bioreactor Cooling

Each cooling method offers a different way to create the necessary surface area for heat transfer between the warm culture and a cold utility fluid, like chilled water or glycol.

The Jacketed Vessel

This is the most common method for laboratory and pilot-scale bioreactors. The reactor is constructed as a double-walled vessel, and coolant flows through the space, or "jacket," between the inner and outer walls.

This design is simple, non-invasive, and easy to clean. However, its effectiveness is limited by the reactor's surface area.

Internal Cooling Coils

For processes with a very high heat load, pipes or coils can be installed directly inside the bioreactor. A cooling fluid is then circulated through these internal coils.

Because they are submerged directly in the culture, coils offer excellent heat transfer efficiency. They provide a large cooling surface area in a compact space.

External Heat Exchangers

In this configuration, a portion of the cell culture is continuously pumped out of the bioreactor, through an external heat exchanger (typically a plate-and-frame unit), and then returned to the vessel.

This "pump-around loop" is extremely effective and highly scalable, making it the standard for large, industrial-scale fermenters where jackets and coils are insufficient.

Understanding the Trade-offs

Choosing a cooling method is a balancing act between thermal performance, process integrity, and operational complexity. There is no single "best" solution.

The Surface Area vs. Volume Challenge

This is the fundamental problem of scaling up a bioprocess. A vessel's volume (and thus its heat-generating potential) increases by the cube of its radius (r³), while its surface area (its heat-shedding ability) only increases by the square (r²).

This means a large bioreactor has proportionally less jacket surface area to remove its internal heat, which is why a jacket that works for a 10L reactor will fail for a 10,000L one.

Shear Stress and Cell Viability

Mechanical forces, known as shear stress, can damage or kill cells. Robust organisms like bacteria and yeast are relatively resilient.

However, fragile mammalian and insect cells are highly susceptible to shear. The high-speed agitation around internal coils or the journey through a pump in an external loop can reduce cell viability, making non-invasive jackets the preferred choice when possible.

Sterility and Cleaning Concerns

Maintaining a sterile environment is paramount. A simple jacketed vessel with no internal components is the easiest to clean and sterilize.

Internal coils, with their welds and surfaces, can be a potential site for biofilm growth, making cleaning (Clean-In-Place, CIP) more challenging. External heat exchangers add pumps, gaskets, and piping, increasing the number of potential failure points for contamination.

Selecting the Right Cooling Strategy

Your choice must be guided by your process scale, the metabolic rate of your organism, and the cell line's sensitivity to physical stress.

- If your primary focus is lab or pilot-scale processes (<500L): A jacketed vessel is almost always the most practical, cost-effective, and lowest-risk solution.

- If your primary focus is high-intensity microbial fermentation: Internal coils or an external heat exchanger are often necessary to handle the high metabolic heat load, as a jacket alone will be insufficient.

- If your primary focus is large-scale industrial production (>1,000L): An external pump-around loop with a plate-and-frame heat exchanger is the industry standard due to its superior scalability and cooling capacity.

- If your primary focus is a shear-sensitive cell culture (e.g., mammalian): Prioritize a jacketed vessel. If more cooling is needed at larger scales, you must use a carefully designed low-shear pump for an external loop.

Ultimately, effective temperature control is the foundation of a stable and productive bioprocess.

Summary Table:

| Cooling Method | Best For | Key Advantages | Key Considerations |

|---|---|---|---|

| Jacketed Vessel | Lab/Pilot Scale (<500L), Shear-Sensitive Cells | Non-invasive, easy to clean/sterilize | Limited surface area for large-scale heat removal |

| Internal Coils | High-Intensity Fermentation | Excellent heat transfer, large surface area in compact space | Potential for biofilm, harder to clean |

| External Heat Exchanger | Large-Scale Production (>1,000L) | Highly scalable and efficient | Adds complexity, risk of shear stress and contamination |

Struggling with temperature control in your bioprocess? KINTEK specializes in precision lab equipment, including bioreactors with advanced cooling systems tailored to your specific scale and cell line requirements. Our experts can help you select the right configuration—from benchtop jackets to industrial-scale external loops—to ensure optimal cell viability and maximum product yield. Contact our team today to discuss your bioreactor cooling needs and achieve stable, productive cultures.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- High Performance Laboratory Freeze Dryer

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method