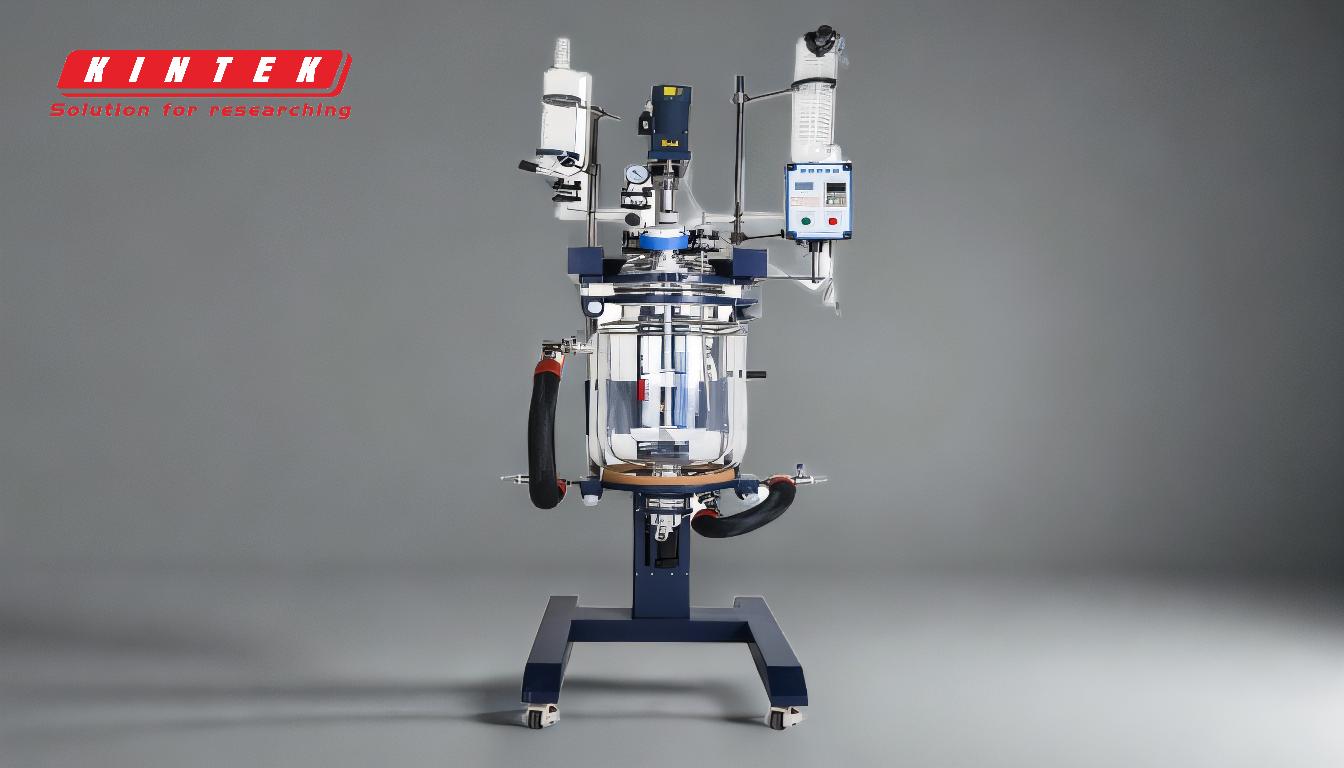

A glass reactor is a versatile piece of equipment used in chemical processes to facilitate reactions under controlled conditions. It operates by stirring and reacting substances in a sealed glass vessel, often under normal or negative pressure, while maintaining a constant temperature. The reactor controls the evaporation and reflux of the reaction solution, ensuring efficient mixing and reaction progression. Key components include a glass vessel, an agitator, baffles for turbulence, and ports for adding or recovering materials. Glass reactors are available in various configurations, such as single-layer, double-layer, and three-layer designs, and are commonly made from borosilicate glass for durability and chemical resistance.

Key Points Explained:

-

Basic Functionality of a Glass Reactor:

- A glass reactor is designed to facilitate chemical reactions in a controlled environment. It operates by stirring and reacting substances in a sealed glass vessel, often under normal or negative pressure, and at a set constant temperature.

- The reactor controls the evaporation and reflux of the reaction solution, ensuring that the reaction proceeds efficiently and safely.

-

Key Components:

- Glass Vessel: The main body of the reactor, typically made from borosilicate glass, which is resistant to thermal shock and chemical corrosion. The vessel comes in various sizes, ranging from 50ml to 200L.

- Agitator: A centrally mounted stirrer that mixes the chemicals within the reactor. The agitator ensures that the reactants are well-mixed, promoting uniform reaction conditions.

- Baffles: These are internal components that create turbulence within the reactor, enhancing the mixing efficiency and preventing the formation of stagnant zones.

- Sealed Container: The reactor is sealed to control the pressure and prevent the escape of volatile substances. This is crucial for reactions that require specific pressure conditions.

- Ports and Valves: The reactor lid is equipped with ports or valves for connecting accessories such as condensers, thermo-probes, or material addition lines. A drain port at the bottom allows for the emptying or recirculation of the liquid contents.

-

Temperature Control:

- The reactor often includes an integral heating/cooling system, which may be a jacket surrounding the glass vessel. This system allows for precise temperature control, which is essential for many chemical reactions.

- The temperature can be adjusted to maintain a constant reaction temperature, ensuring consistent reaction rates and product quality.

-

Pressure Control:

- Glass reactors can operate under normal pressure or negative pressure (vacuum). Negative pressure is often used to lower the boiling point of solvents, facilitating reactions that require low temperatures.

- The sealed nature of the reactor allows for the control of pressure, which is critical for reactions that are sensitive to atmospheric conditions.

-

Types of Glass Reactors:

- Single-Layer Reactor: The simplest form, with a single glass wall. It is suitable for reactions that do not require extensive temperature control.

- Double-Layer Reactor: Features an inner and outer layer, with the space between them used for circulating heating or cooling fluids. This design allows for better temperature control.

- Three-Layer Reactor: Offers additional layers for enhanced temperature control and insulation, making it suitable for more complex reactions.

-

Applications:

- Glass reactors are used in a wide range of applications, including chemical synthesis, pharmaceutical production, and material science research.

- They are particularly useful for reactions that require precise control over temperature, pressure, and mixing.

-

Advantages:

- Chemical Resistance: Borosilicate glass is highly resistant to most chemicals, making it suitable for a wide range of reactions.

- Transparency: The glass allows for visual monitoring of the reaction, which is useful for observing changes in color, phase, or consistency.

- Temperature and Pressure Control: The ability to precisely control temperature and pressure makes glass reactors ideal for sensitive reactions.

-

Considerations for Purchasers:

- Size and Capacity: The size of the reactor should be chosen based on the scale of the reactions to be performed. Smaller reactors are suitable for laboratory-scale experiments, while larger reactors are used for industrial production.

- Material Compatibility: Ensure that the glass material is compatible with the chemicals to be used in the reactor.

- Temperature and Pressure Requirements: Consider the temperature and pressure ranges required for the reactions, and choose a reactor with appropriate heating/cooling and pressure control capabilities.

- Accessories and Ports: Evaluate the need for additional accessories such as condensers, thermo-probes, or material addition lines, and ensure that the reactor has the necessary ports and valves.

In summary, a glass reactor is a critical piece of equipment for conducting controlled chemical reactions. Its design, which includes a glass vessel, agitator, baffles, and temperature/pressure control systems, allows for precise control over reaction conditions. Understanding the key components and their functions, as well as the different types of reactors available, is essential for selecting the right equipment for specific applications.

Summary Table:

| Aspect | Details |

|---|---|

| Key Components | Glass vessel, agitator, baffles, sealed container, ports and valves |

| Temperature Control | Integral heating/cooling system for precise reaction conditions |

| Pressure Control | Operates under normal or negative pressure (vacuum) for specific reactions |

| Types | Single-layer, double-layer, three-layer designs |

| Applications | Chemical synthesis, pharmaceutical production, material science research |

| Advantages | Chemical resistance, transparency, precise temperature/pressure control |

| Considerations | Size, material compatibility, temperature/pressure requirements, accessories |

Ready to enhance your chemical processes? Contact us today to find the perfect glass reactor for your needs!