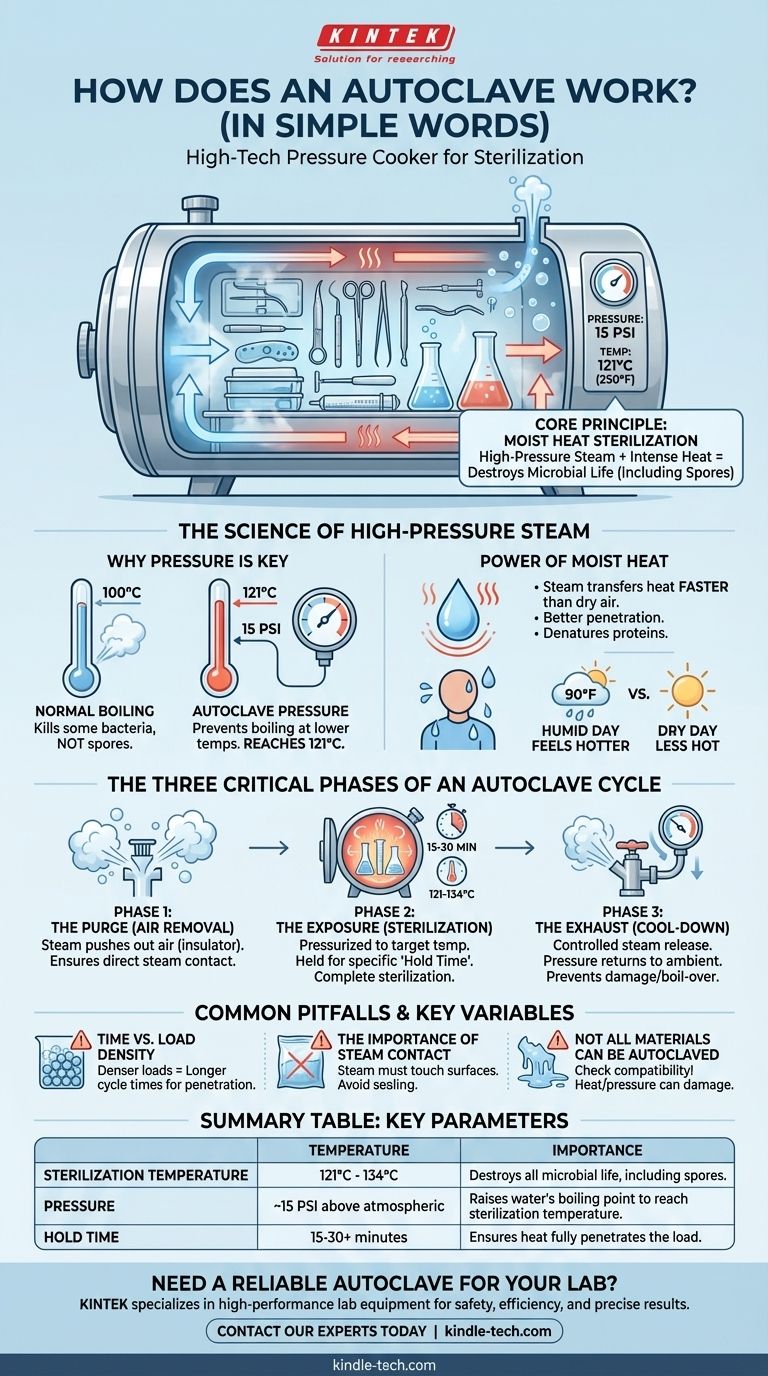

In simple terms, an autoclave is a high-tech pressure cooker for sterilization. It uses the combined power of high-pressure steam and intense heat to destroy all forms of microbial life, including bacteria, viruses, fungi, and even the resilient spores that boiling water alone cannot kill. This process ensures that medical instruments, lab equipment, and other materials are completely sterile.

The fundamental principle is moist heat sterilization. By increasing pressure inside a sealed chamber, an autoclave raises the boiling point of water well above 100°C (212°F). This creates superheated steam that rapidly penetrates materials and transfers lethal heat far more efficiently than dry air.

The Science of High-Pressure Steam

To understand how an autoclave works, you must first understand why simple boiling is not enough for true sterilization.

Why Pressure is the Key Ingredient

Water normally boils at 100°C (212°F) at standard atmospheric pressure. While this temperature kills many bacteria, it is not sufficient to eliminate highly resistant bacterial spores.

By sealing the chamber and increasing the pressure, an autoclave prevents water from boiling at its normal temperature. For example, at a pressure of 15 pounds per square inch (PSI) above atmospheric pressure, water doesn't boil until it reaches 121°C (250°F).

The Power of Moist Heat

Moist heat (steam) is a dramatically more effective agent for sterilization than dry heat. It transfers thermal energy much faster, allowing it to penetrate dense materials and quickly denature the essential proteins and cellular structures of microorganisms.

Think of it like the weather: a 90°F day with high humidity feels much hotter and more oppressive than a 90°F day in a dry desert because the moisture in the air transfers heat to your body more efficiently. The steam in an autoclave works on the same principle.

The Three Critical Phases of an Autoclave Cycle

An autoclave doesn't just heat up and cool down. It follows a precise, multi-stage process to ensure complete sterilization.

Phase 1: The Purge (Air Removal)

Before sterilization can begin, all air must be removed from the chamber. Air pockets act as an insulating barrier that prevents steam from making direct contact with the surfaces of the items inside.

The autoclave purges this air by flooding the chamber with steam, which is lighter than air and displaces it through vents. This ensures the chamber is filled only with saturated steam.

Phase 2: The Exposure (Sterilization)

Once all air is removed, the chamber is fully pressurized and brought to the target sterilization temperature, typically between 121°C and 134°C.

The load is held at this temperature and pressure for a specific duration, known as the "hold time." A typical cycle for general lab equipment is at least 15 minutes at 121°C, but this can extend to 30 minutes or more depending on the contents.

Phase 3: The Exhaust (Cool-Down)

After the hold time is complete, the steam is slowly released from the chamber through an exhaust valve. This allows the internal pressure to return to ambient levels.

The cooling process is managed carefully to prevent liquids from boiling over or sealed containers from breaking due to a sudden pressure drop. Once the cycle is finished, the sterilized items can be safely removed.

Common Pitfalls and Key Variables

Effective autoclaving is more than just pushing a button. Several factors can compromise the outcome if not properly managed.

Time vs. Load Density

A common mistake is assuming a standard cycle time is sufficient for every load. Densely packed instruments or large liquid volumes require significantly longer cycle times to ensure heat penetrates to the very center of the load.

The Importance of Steam Contact

Sterilization only occurs where steam makes direct contact. Items inside tightly sealed or non-permeable bags will not be sterilized. Likewise, overloading the chamber can create air pockets and block steam pathways, resulting in an incomplete cycle.

Not All Materials Can Be Autoclaved

The combination of high heat and pressure will damage or destroy many materials. Heat-sensitive plastics will melt, sharp instruments can become dull, and certain liquids or chemicals can break down or release toxic fumes. Always verify material compatibility before autoclaving.

Making the Right Choice for Your Goal

Understanding the autoclave's function ensures you use it effectively and safely for its intended purpose.

- If your primary focus is ensuring complete sterilization: Prioritize proper loading techniques and air removal to guarantee steam makes direct contact with every surface.

- If your primary focus is operational efficiency: Recognize that cycle time must be adjusted based on the size and density of the load, as a "one-size-fits-all" approach often leads to failed sterilization.

- If your primary focus is safety and material integrity: Always verify that your materials can withstand high temperatures and pressure to prevent damage to the equipment and the autoclave itself.

By mastering these core principles, you transform the autoclave from a simple machine into a reliable and precise scientific instrument.

Summary Table:

| Key Autoclave Parameter | Typical Value | Importance |

|---|---|---|

| Sterilization Temperature | 121°C - 134°C | Destroys all microbial life, including spores. |

| Pressure | ~15 PSI above atmospheric | Raises water's boiling point to reach sterilization temperature. |

| Hold Time | 15-30+ minutes | Ensures heat fully penetrates the load for complete sterilization. |

Need a reliable autoclave for your lab's sterilization needs?

KINTEK specializes in high-performance lab equipment, including autoclaves designed for safety, efficiency, and precise results. Whether you're processing medical instruments, lab glassware, or culture media, our solutions ensure complete sterilization to protect your work and maintain compliance.

Contact our experts today to find the perfect autoclave for your laboratory's specific requirements and ensure your sterilization protocols are flawless.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- Which is better dry-heat or steam autoclave? Choose the Right Sterilization Method

- Why is an autoclave the most effective sterilizer? Unlock the Power of Pressurized Steam for Guaranteed Sterility

- Why are high-pressure autoclaves required for Zirconium alloy testing? Essential for Nuclear Environment Validation

- What is the purpose of the autoclave test? Ensuring Sterilization Effectiveness and Safety

- What is the purpose and use of an autoclave? Achieve Complete Sterilization for Your Lab

- What are the limitations of autoclave sterilization? Avoid Costly Damage to Your Lab Equipment

- How does an autoclave contribute to the reliability of results in biofilm formation experiments? Ensure Data Integrity

- What are the functions of an autoclave and alumina liner in LBE experiments? Protect Your Research & Data Integrity.