As a matter of best practice, a laboratory water bath should be fully drained, cleaned, and refilled on a weekly basis. This routine is essential not only to prevent the buildup of mineral salts and biological contaminants but also to actively protect the unit from corrosion and ensure its long-term operational integrity.

Weekly cleaning is more than a simple housekeeping task; it is a critical maintenance procedure that directly prevents both the contamination of your experiments and the physical degradation of the equipment itself.

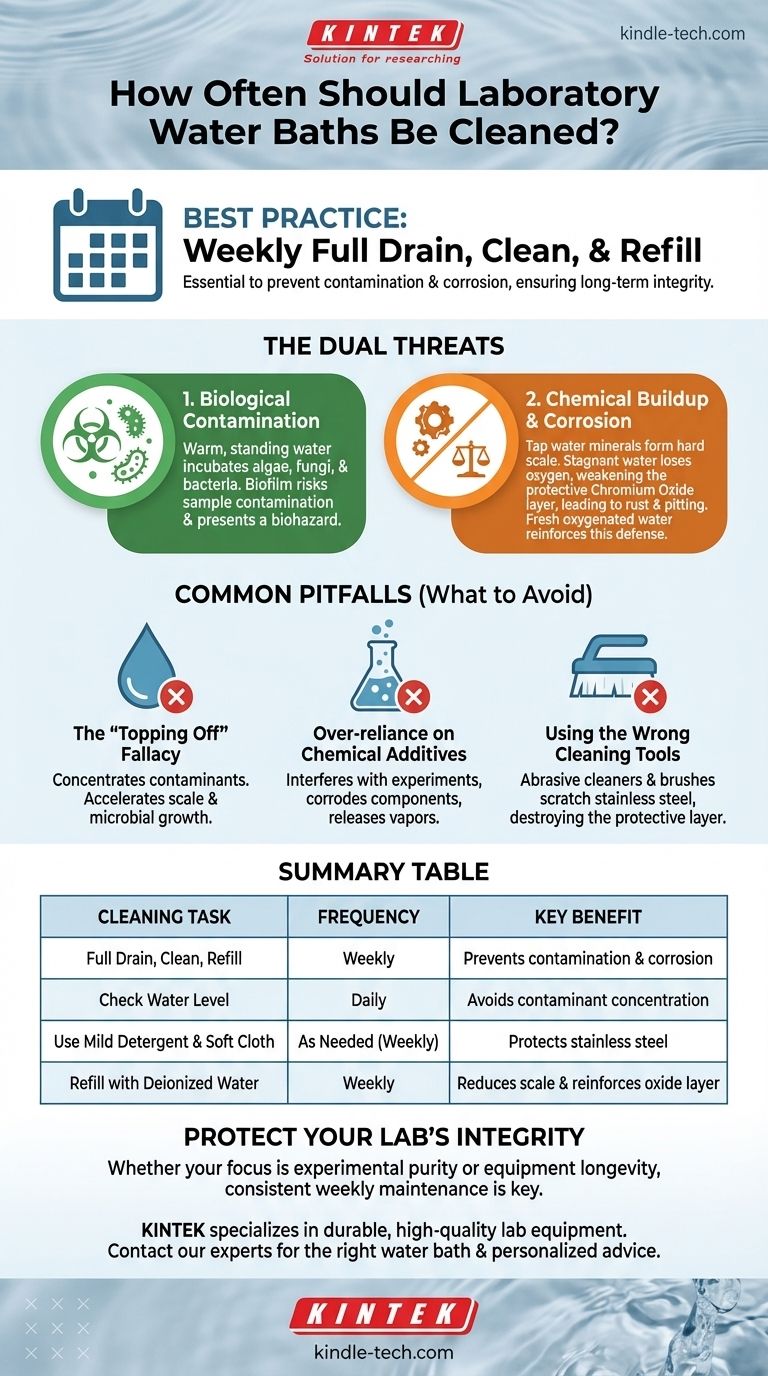

The Dual Threats to Your Water Bath

Failure to maintain a water bath introduces two distinct risks: one that compromises your scientific results and another that physically damages the equipment. Understanding both is key to appreciating the importance of a consistent cleaning schedule.

Preventing Biological Contamination

Warm, standing water is an ideal incubator for algae, fungi, and bacteria. Without weekly cleaning, these microorganisms can flourish.

This biofilm can become a source of contamination for your samples, potentially skewing or invalidating experimental results. It also presents a potential biohazard in the lab environment.

Combating Chemical Buildup and Corrosion

Tap water contains dissolved minerals and salts. As water evaporates, these deposits become concentrated, forming a hard scale on the bath's surfaces that can be difficult to remove.

More importantly, the integrity of a stainless steel bath depends on a microscopic, passive layer of chromium oxide. This protective shield requires oxygen to form and maintain itself. Stagnant water loses its dissolved oxygen, weakening this layer and making the steel vulnerable to rust and pitting. Weekly refilling replenishes the oxygen, reinforcing this crucial defense.

Understanding the Common Pitfalls

Adopting the right maintenance routine involves avoiding common but flawed shortcuts. These mistakes can seem harmless but ultimately undermine the goals of cleaning.

The "Topping Off" Fallacy

Simply adding more water to compensate for evaporation is a frequent mistake. This practice only exacerbates the problem.

Topping off concentrates the existing mineral salts and biological contaminants, accelerating scale buildup and providing more "food" for microbial growth. It fails to remove the contaminants that have already accumulated.

Over-reliance on Chemical Additives

While algicides or disinfectants might seem like an easy solution, they introduce their own set of problems.

These chemicals can interfere with sensitive experiments, corrode the bath's tank and components, or release vapors into the lab. The most reliable method is physical cleaning and replacement with clean, deionized water.

Using the Wrong Cleaning Tools

Never use abrasive cleaners, steel wool, or hard-bristled brushes on a stainless steel water bath.

These tools will scratch the surface, destroying the protective chromium oxide layer and creating sites where corrosion can begin immediately. Always use a soft cloth or sponge with a mild detergent.

Making the Right Choice for Your Lab's Integrity

Your approach to water bath maintenance should be guided by your specific priorities, whether they are experimental purity or asset preservation.

- If your primary focus is preventing sample contamination: Treat the weekly water change as your first line of defense against microbial growth that can ruin your data.

- If your primary focus is equipment longevity: Understand that refilling with fresh, oxygenated water is an active step that prevents rust and extends the working life of the unit.

Consistent weekly maintenance transforms cleaning from a chore into a fundamental practice for reliable science.

Summary Table:

| Cleaning Task | Frequency | Key Benefit |

|---|---|---|

| Full Drain, Clean, Refill | Weekly | Prevents biological contamination and equipment corrosion |

| Check Water Level | Daily | Avoids concentration of contaminants from evaporation |

| Use Mild Detergent & Soft Cloth | As Needed (Weekly) | Protects stainless steel surface from scratches |

| Refill with Deionized Water | Weekly | Reduces mineral scale and reinforces protective oxide layer |

Ensure your lab's experiments and equipment are protected with reliable water bath maintenance. KINTEK specializes in high-quality lab equipment and consumables designed for durability and easy upkeep. Our water baths are built to withstand rigorous use, but proper care is key to their longevity and performance.

Contact our experts today to find the right water bath for your needs or to get personalized maintenance advice. Let KINTEK help you maintain the integrity of your lab work.

Visual Guide

Related Products

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- 50L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 30L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 10L Chilling Circulator Cooling Water Bath Low Temperature Constant Temperature Reaction Bath

People Also Ask

- Why is a recirculating thermostatic bath required for high-precision CV testing? Ensure Accurate Electrochemical Data

- Why are constant temperature water baths used in refractory testing? Accelerate MgO Hydration & Binder Evaluation

- Why do manganese electrolysis processes require a thermostatic water bath? Master Thermal Control for High-Purity Metal

- What is the primary role of a constant temperature water bath in biomass washing? Optimize Poplar Pretreatment.

- How does a thermostatic water bath function in ODS steel corrosion tests? Ensure Precise Bio-Simulation Accuracy