Evaporating ethanol from an extract using a rotary evaporator is a common process in laboratories, particularly in cannabis extraction or other solvent-based extractions. The rotary evaporator (rotovap) is designed to efficiently remove solvents like ethanol under reduced pressure, which lowers the boiling point of the solvent and minimizes heat exposure to the extract. The process involves creating a vacuum, rotating the flask to increase surface area, heating the solution, and condensing the evaporated ethanol for collection. Proper operation ensures the preservation of the extract's quality while effectively removing the ethanol.

Key Points Explained:

-

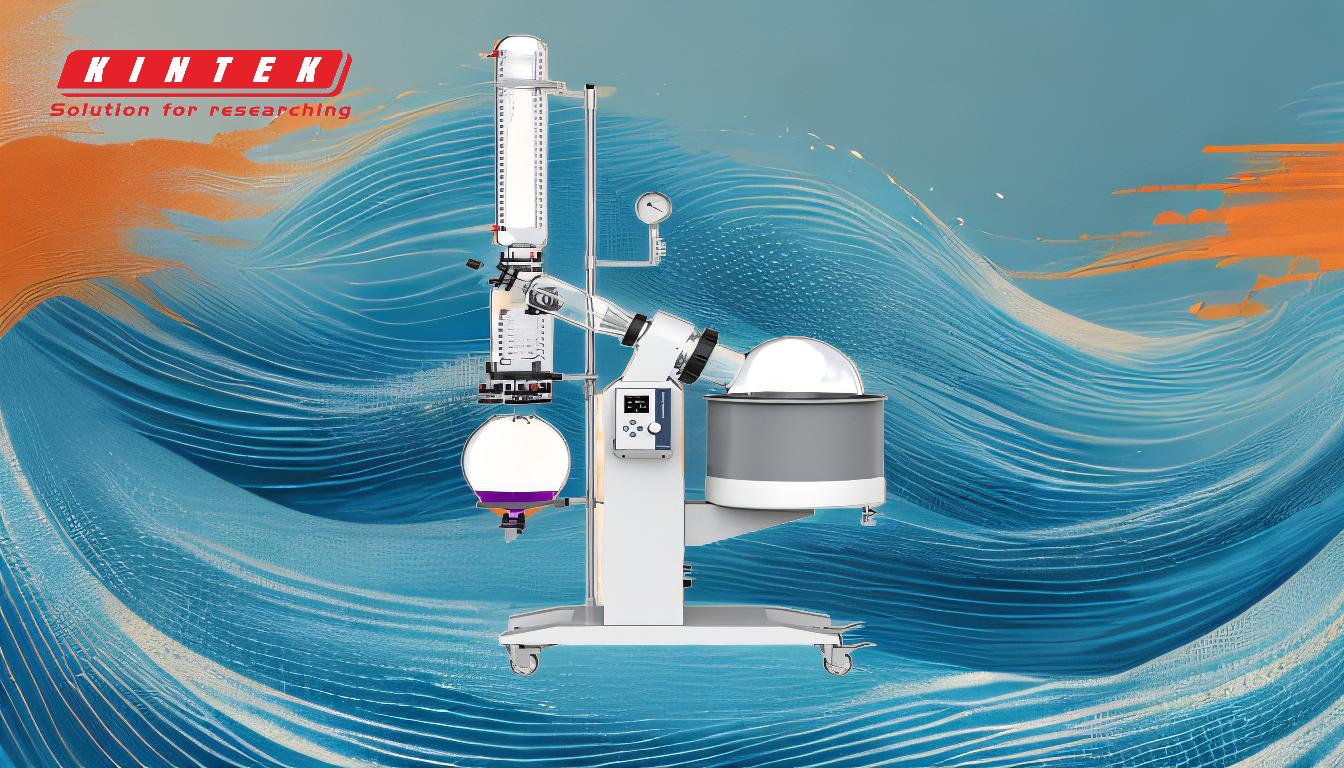

Understanding the Rotary Evaporator Mechanism:

- The rotary evaporator operates by reducing pressure inside the system, which lowers the boiling point of ethanol, allowing it to evaporate at lower temperatures.

- The evaporation flask rotates, creating a thin film of the extract-ethanol mixture on the flask's inner walls, increasing the surface area for faster evaporation.

- A heated fluid bath (often water) provides controlled heat to the flask, promoting the evaporation of ethanol.

- The evaporated ethanol is condensed using a chilled condenser and collected in a separate flask.

-

Preparation for Ethanol Evaporation:

- Ensure the rotary evaporator is clean and properly assembled, with all connections securely tightened to maintain the vacuum.

- Set up the water bath at an appropriate temperature (typically 30-40°C for ethanol) to avoid overheating the extract.

- Fill the condenser with a cooling medium (e.g., ice water or a chiller) to ensure efficient condensation of ethanol vapors.

- Check the vacuum pump to ensure it is functioning correctly and can achieve the desired pressure.

-

Loading the Extract-Ethanol Mixture:

- Transfer the extract-ethanol mixture into the evaporation flask, ensuring it does not exceed 50% of the flask's capacity to prevent spillage during rotation.

- Securely attach the flask to the rotary evaporator, ensuring a proper seal to maintain the vacuum.

-

Operating the Rotary Evaporator:

- Start the rotation at a moderate speed (e.g., 100-150 rpm) to create a thin film of the mixture on the flask walls.

- Gradually increase the vacuum pressure to lower the boiling point of ethanol. Monitor the system for condensation or bubbling, which indicates ethanol evaporation.

- Adjust the water bath temperature and vacuum pressure as needed to maintain a steady evaporation rate without overheating the extract.

- Continue the process until no more ethanol condenses into the collection flask, indicating complete removal.

-

Post-Evaporation Steps:

- Once all ethanol has been evaporated, turn off the rotation and vacuum pump.

- Carefully remove the evaporation flask, ensuring no residual extract is lost.

- Clean the rotary evaporator components thoroughly to prevent cross-contamination in future uses.

-

Safety Considerations:

- Always wear appropriate personal protective equipment (PPE), including gloves and safety goggles, when handling solvents and operating the rotary evaporator.

- Ensure the workspace is well-ventilated to avoid inhaling ethanol vapors.

- Regularly inspect the equipment for leaks or damage to prevent accidents.

-

Optimizing the Process:

- Adjust the rotation speed, water bath temperature, and vacuum pressure based on the volume and composition of the extract-ethanol mixture.

- Use a cold trap or dry ice condenser for more efficient condensation of ethanol, especially when working with large volumes.

- Monitor the process closely to avoid over-concentration or degradation of the extract.

By following these steps, you can effectively and safely evaporate ethanol from an extract using a rotary evaporator, ensuring high-quality results while preserving the integrity of the extract.

Summary Table:

| Step | Key Actions |

|---|---|

| Preparation | Clean and assemble the rotary evaporator. Set water bath to 30-40°C. |

| Loading the Mixture | Transfer extract-ethanol mixture, ensuring ≤50% flask capacity. Secure seal. |

| Operation | Start rotation (100-150 rpm). Gradually increase vacuum pressure. Monitor. |

| Post-Evaporation | Turn off rotation and vacuum. Remove flask carefully. Clean equipment. |

| Safety | Wear PPE, ensure ventilation, and inspect equipment regularly. |

| Optimization | Adjust speed, temperature, and pressure. Use cold traps for efficiency. |

Need help with your rotary evaporator setup? Contact our experts today for personalized guidance!