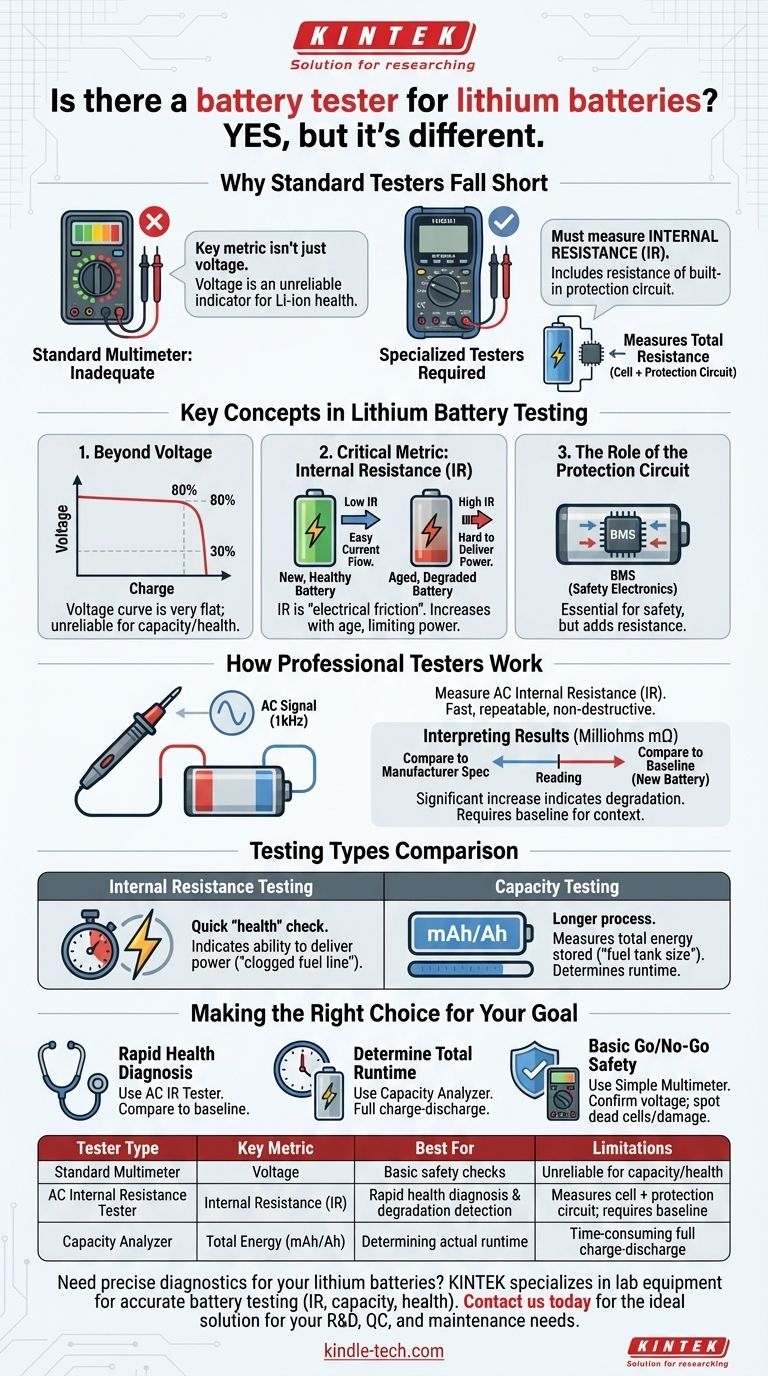

Yes, specialized testers for lithium batteries exist, but testing them is fundamentally different than testing simpler alkaline or lead-acid batteries. A standard multimeter or basic "green/yellow/red" tester is inadequate because the key metric isn't just voltage. True assessment requires measuring the battery's internal resistance (IR), a task complicated by the battery's own built-in safety electronics.

While professional instruments can measure a lithium battery's internal resistance to diagnose its health, the reading almost always includes the resistance of the integrated protection circuit. Understanding this distinction is the key to getting a meaningful result.

Why Standard Testers Fall Short for Lithium Batteries

To properly test a lithium-ion (Li-ion) battery, you need to look beyond the simple metrics used for older battery chemistries. The process requires a more sophisticated understanding of how these batteries function and degrade.

Beyond Simple Voltage Checks

For most of its discharge cycle, a Li-ion battery maintains a very flat voltage curve. This means a battery at 80% charge and one at 30% charge may show nearly identical voltage, making voltage an unreliable indicator of its remaining capacity or overall health.

The Critical Metric: Internal Resistance (IR)

The most important metric for a battery's health is its internal resistance (IR). Think of IR as electrical "friction" inside the battery.

A new, healthy battery has very low IR, allowing it to deliver current easily. As a battery ages and degrades through use and time, its IR increases, making it harder for the battery to deliver power, especially under high load.

The Role of the Protection Circuit

Nearly all consumer and industrial Li-ion batteries include a protection circuit or a more advanced Battery Management System (BMS). This circuit is critical for safety, preventing over-charge, over-discharge, and excessive current. However, this essential safety feature is wired in series with the cell, meaning it has its own resistance.

How Professional Lithium Battery Testers Work

Specialized testers are designed to overcome these challenges by focusing on the correct metrics and using specific techniques to measure them accurately.

Measuring AC Internal Resistance

Professional testers, like the Hioki BT3554 mentioned in technical literature, don't just measure DC voltage. They use a low-frequency AC signal (typically 1kHz) to measure the battery's AC internal resistance. This method provides a fast, repeatable, and non-destructive way to assess the battery's internal state.

Interpreting the Results

A tester provides a resistance value, typically in milliohms (mΩ). This number is not an absolute "good" or "bad" score on its own. Its value comes from comparison—either to the manufacturer's specification for a new battery or to a baseline reading taken when the battery pack was known to be healthy. A significant increase in IR indicates degradation.

Capacity Testing vs. Resistance Testing

It's important to distinguish between two types of tests.

- Internal Resistance Testing: A quick "health" check that indicates the battery's ability to deliver power.

- Capacity Testing: A much longer process that involves a full charge followed by a controlled discharge to measure the total energy (in mAh or Ah) the battery can hold. This tells you "how big the tank is," while IR tells you "how clogged the fuel line is."

Understanding the Trade-offs and Challenges

Even with the right tool, testing lithium batteries involves understanding key limitations. Your interpretation of the data is as important as the measurement itself.

The Protection Circuit's Influence

When you measure a battery with a built-in BMS, the tester measures the total resistance of the lithium cell plus the resistance of the protection circuit's components (like MOSFETs and fuses). This is an unavoidable reality of testing protected batteries and must be factored into your analysis.

The Need for a Baseline

A single IR measurement in isolation is of little use. The power of this technique lies in trending data over time. A 20% increase in IR from its initial value often signals that the battery is approaching the end of its useful life, even if its capacity still seems acceptable.

Cost and Application

Professional AC IR testers are expensive precision instruments, often costing hundreds or thousands of dollars. They are designed for technicians maintaining critical systems like uninterruptible power supplies (UPS) or electric vehicle battery packs. For many hobbyists, a simpler and cheaper capacity tester is a more practical tool.

Making the Right Choice for Your Goal

The right testing method depends entirely on what you need to find out.

- If your primary focus is rapid health diagnosis: Use an AC internal resistance tester and compare the reading to a known-good battery or a baseline measurement to detect degradation.

- If your primary focus is determining total runtime: Use a dedicated capacity analyzer that performs a full charge-discharge cycle to measure the total energy stored in the battery.

- If your primary focus is basic go/no-go safety: A simple multimeter check can confirm voltage and identify completely dead cells (0V), while a visual inspection can spot swelling or damage.

By choosing the right tool for your specific goal, you can move from simple guessing to making an accurate, data-driven assessment of your battery's condition.

Summary Table:

| Tester Type | Key Metric Measured | Best For | Limitations |

|---|---|---|---|

| Standard Multimeter | Voltage | Basic go/no-go safety checks | Unreliable for Li-ion capacity/health |

| AC Internal Resistance Tester | Internal Resistance (IR) | Rapid health diagnosis & degradation detection | Measures cell + protection circuit resistance; requires baseline |

| Capacity Analyzer | Total Energy (mAh/Ah) | Determining actual runtime | Time-consuming full charge-discharge cycle |

Need precise diagnostics for your lithium batteries? KINTEK specializes in lab equipment and consumables, providing reliable tools for accurate battery testing and analysis. Our expertise ensures you get the right equipment to assess internal resistance, capacity, and overall battery health—critical for R&D, quality control, and maintenance. Contact us today (#ContactForm) to find the ideal testing solution for your laboratory needs!

Visual Guide

Related Products

- Filter Testing Machine FPV for Dispersion Properties of Polymers and Pigments

- Aluminum Foil Current Collector for Lithium Battery

- Battery Lab Equipment 304 Stainless Steel Strip Foil 20um Thick for Battery Test

- Nickel Aluminum Tabs for Soft Pack Lithium Batteries

- Customizable PEM Electrolysis Cells for Diverse Research Applications

People Also Ask

- Why are gloveboxes and hydraulic pellet presses required for lithium-sulfur battery assembly? Key Tools for Efficiency

- Purpose of Copper Foil in Sodium Battery Testing: Key for Measuring Coulombic Efficiency and Safety

- What are the specific long-term storage instructions for carbon felt? Prevent Contamination & Ensure Performance

- Why is a customized pressure device used for solid-state batteries? Master Stack Pressure for Stable Battery Cycling

- How should carbon paper used in a fuel cell be maintained? Prevent PTFE Degradation for Peak Performance

- What is the function of a magnetic stirring heating device in silver nanoparticle synthesis? Precision Control for Battery Collectors

- How is a precision doctor blade coater utilized in constructing multi-layered SCPE structures? Precise Layering Guide

- Why is precision mixing and shaping equipment required for composite cathodes in solid-state batteries?