In short, optical coatings are made from a diverse range of materials, primarily falling into three categories: metals, dielectric compounds (like ceramics), and specialized polymers. These materials are deposited in extremely thin, precise layers to control how light interacts with a surface, such as the lens of a camera or a pair of eyeglasses.

The specific material chosen for an optical coating is not arbitrary. It is a calculated decision based on the desired optical function—such as anti-reflection or high-reflectivity—and the physical demands of the operating environment.

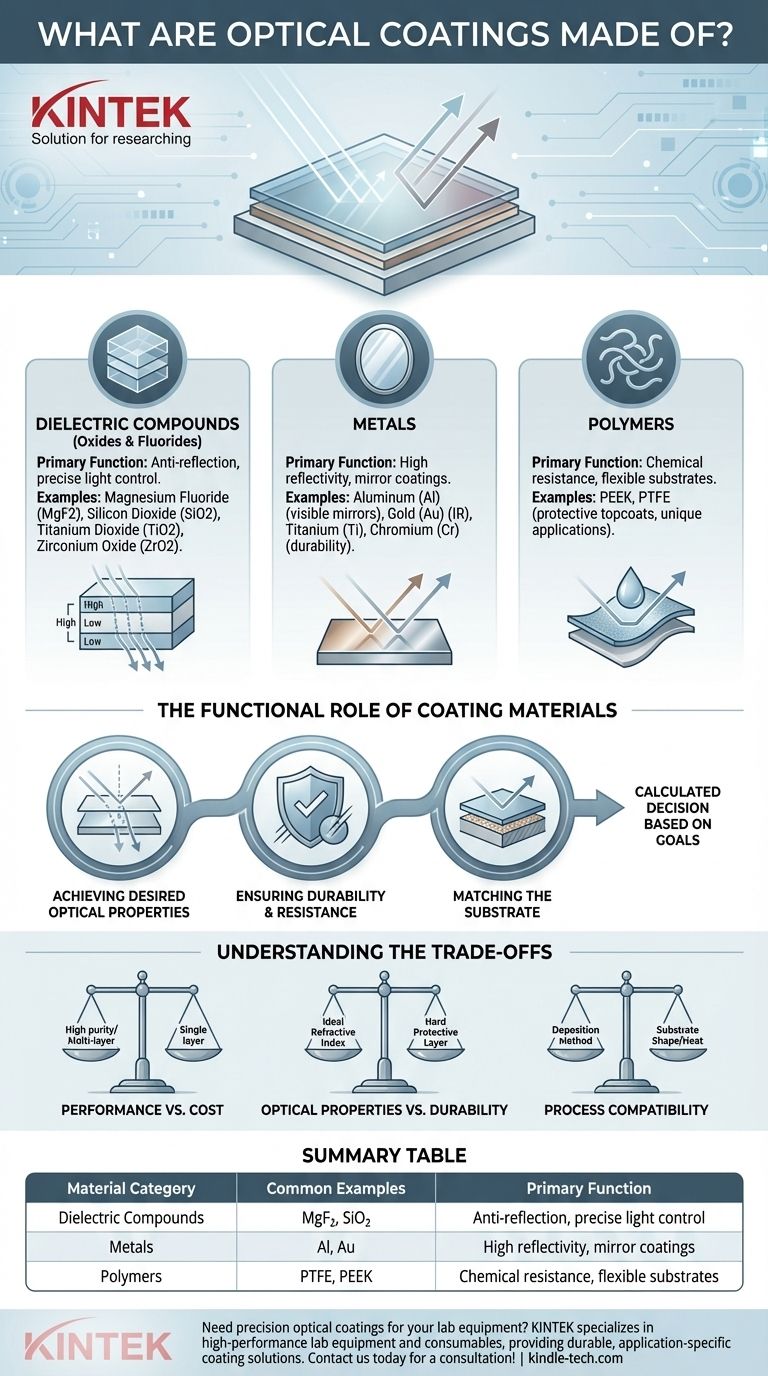

The Functional Role of Coating Materials

Understanding why certain materials are used is more important than memorizing a list. The choice is driven by three primary goals: achieving a specific optical effect, ensuring durability, and compatibility with the underlying surface (the substrate).

Achieving Desired Optical Properties

The fundamental purpose of an optical coating is to manipulate light. Materials are chosen for their intrinsic optical properties, such as their refractive index and ability to absorb or transmit light at different wavelengths.

By depositing alternating layers of materials with high and low refractive indices, engineers can precisely control which wavelengths of light are reflected and which are transmitted.

Ensuring Durability and Resistance

An optical coating is useless if it scratches or degrades easily. Materials are selected for their mechanical behavior and chemical resistance.

Hard ceramic materials like Zirconium Oxide (ZrO2) or Aluminum Oxide (Al2O3) provide excellent scratch resistance. For applications in harsh chemical environments, inert metals like Platinum (Pt) or polymers like PTFE may be used.

Matching the Substrate

The coating must successfully adhere to the component it is protecting. This underlying component, or substrate, can be anything from glass and plastic to various metals.

The deposition process and material choice must be compatible with the substrate. For example, applying a coating at a very high temperature could damage a plastic substrate, so a different material and process would be required.

A Breakdown of Common Coating Materials

While countless compounds can be used, most fall into a few key families, each serving a distinct purpose.

Dielectric Compounds (Oxides and Fluorides)

These are the most common materials for sophisticated optical coatings, such as anti-reflection (AR) coatings. They are typically transparent in the visible spectrum and do not conduct electricity.

Common examples include Magnesium Fluoride (MgF2), Silicon Dioxide (SiO2), Titanium Dioxide (TiO2), and Zirconium Oxide (ZrO2). They are used in alternating high- and low-index layers to fine-tune light transmission and reflection.

Metals

Metals are primarily used for their high reflectivity. A thin layer of metal can create a highly effective mirror.

Aluminum (Al) is the most common for visible-spectrum mirrors due to its high reflectivity and low cost. Gold (Au) is favored for infrared (IR) applications, and materials like titanium (Ti) and chromium (Cr) are used for their durability and adhesion properties.

Polymers

Polymers are a smaller but important category, often chosen for unique properties.

Materials like PEEK and PTFE offer excellent chemical resistance and can be applied to flexible substrates. They are often used for protective topcoats or in specialized applications where traditional ceramic or metal coatings are unsuitable.

Understanding the Trade-offs in Material Selection

Choosing a coating material is always a balancing act. There is no single "best" material, only the most appropriate one for a given application and budget.

Performance vs. Cost

High-purity materials and complex, multi-layer designs deliver superior optical performance but come at a significantly higher cost. For a consumer product, a simple single-layer coating may be sufficient, whereas a scientific instrument may require a design with dozens of layers of high-purity compounds.

Optical Properties vs. Durability

The material with the ideal refractive index might be soft or prone to absorbing moisture. A common trade-off involves sacrificing a small amount of optical performance for a much more durable and long-lasting coating, often by adding a hard, protective outer layer.

Process Compatibility

Not all materials can be deposited using the same method. The chosen material must be compatible with a deposition process (like Physical Vapor Deposition or PVD) that works for the substrate's shape and heat sensitivity. This can limit the available material options.

Making the Right Choice for Your Application

Your final selection depends entirely on your primary goal.

- If your primary focus is maximizing reflectivity (e.g., a mirror): Your best choice will likely be a simple metallic coating, such as evaporated aluminum or gold.

- If your primary focus is maximizing light transmission (e.g., a lens or window): You will need a multi-layer anti-reflection coating made from alternating layers of dielectric compounds like oxides and fluorides.

- If your primary focus is durability in a harsh environment: Select robust ceramic materials like nitrides or oxides, potentially with a specialized polymer topcoat for chemical resistance.

Ultimately, engineering an optical coating is a process of selecting and combining materials to precisely dictate the behavior of light.

Summary Table:

| Material Category | Common Examples | Primary Function |

|---|---|---|

| Dielectric Compounds | Magnesium Fluoride (MgF2), Silicon Dioxide (SiO2) | Anti-reflection, precise light control |

| Metals | Aluminum (Al), Gold (Au) | High reflectivity, mirror coatings |

| Polymers | PTFE, PEEK | Chemical resistance, flexible substrates |

Need precision optical coatings for your lab equipment? KINTEK specializes in high-performance lab equipment and consumables, providing durable, application-specific coating solutions that enhance light control and longevity. Let our experts help you select the ideal coating material for your project—contact us today for a consultation!

Visual Guide

Related Products

- Evaporation Boat for Organic Matter

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Platinum Auxiliary Electrode for Laboratory Use

People Also Ask

- Why is sputter deposition so much slower than evaporation deposition? Trade Speed for Superior Film Quality

- What is the evaporation process in semiconductors? A Guide to Thin Film Deposition

- Is sputtering physical vapor deposition? The Definitive Guide to PVD Coating Technology

- What is sputtering in physical vapor deposition? A Guide to Atomic-Level Thin Film Coating

- What are the steps in the sputtering process? A Guide to Thin Film Deposition

- What materials are used in optical coating? A Guide to Metal Oxides, Fluorides, and More

- What are the properties of diamond coating? Unlock Extreme Performance for Your Components

- What do optical coatings do? Control Light for Superior Optical Performance