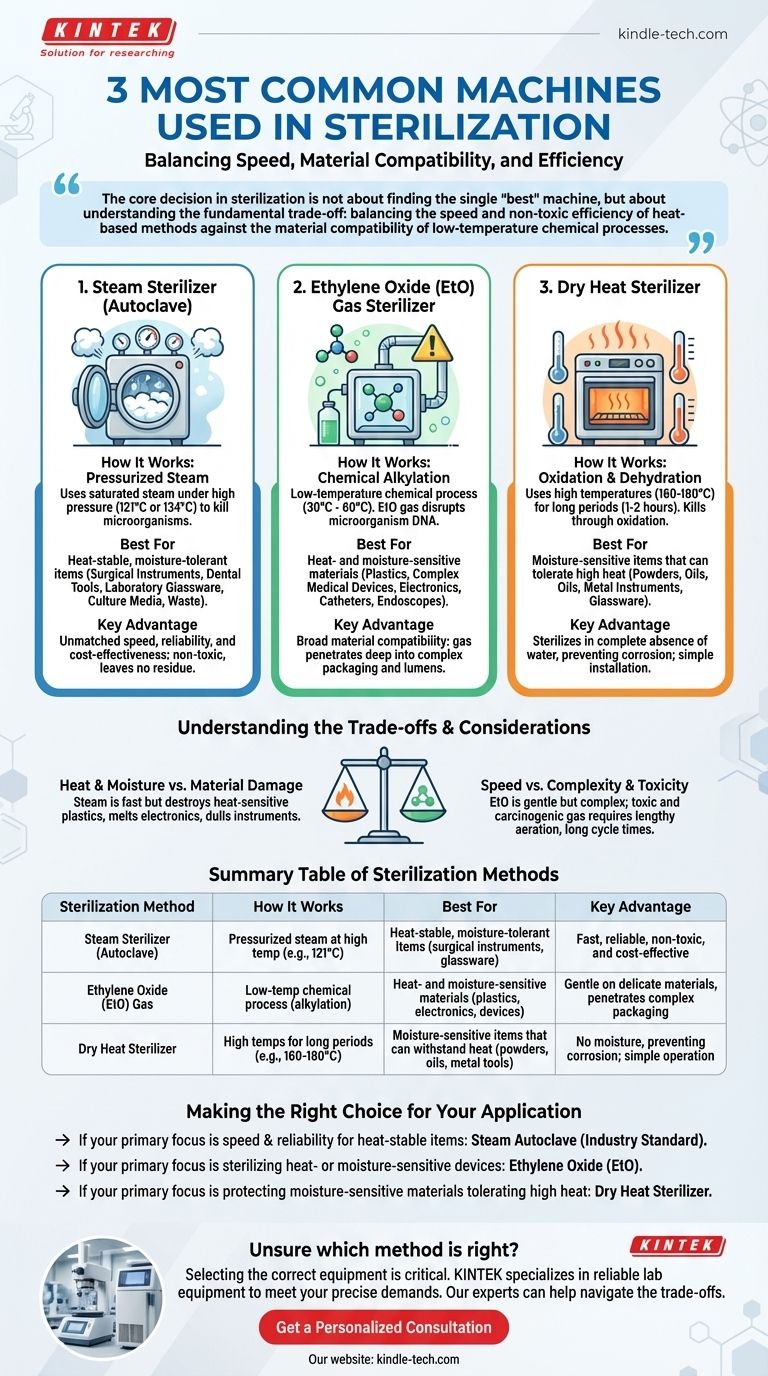

When ensuring absolute sterility, the choice of equipment is critical and depends entirely on the material being treated. The three most common machines used in sterilization are the steam sterilizer (autoclave), the ethylene oxide (EtO) gas sterilizer, and the dry heat sterilizer. Of these, steam sterilization is the most widely used and dependable method for items that can withstand high temperatures and moisture.

The core decision in sterilization is not about finding the single "best" machine, but about understanding the fundamental trade-off: balancing the speed and non-toxic efficiency of heat-based methods against the material compatibility of low-temperature chemical processes.

The Gold Standard: Steam Sterilizers (Autoclaves)

How It Works: Pressurized Steam

An autoclave operates by using saturated steam under high pressure to achieve temperatures that are lethal to all microorganisms, including resilient spores. Common cycles run at 121°C (250°F) or 134°C (273°F).

The combination of moisture and heat is highly effective at denaturing the essential proteins and enzymes within microbes, leading to rapid cell death.

Primary Applications

Autoclaves are the workhorses for sterilizing heat-stable and moisture-tolerant items. This includes surgical and dental instruments, laboratory glassware, medical and pharmaceutical waste, and microbiological culture media.

Key Advantages

The primary advantages of steam sterilization are its unmatched speed, reliability, and cost-effectiveness. Crucially, it leaves behind no toxic residue, making items immediately safe for use after cooling.

For Heat-Sensitive Materials: Ethylene Oxide (EtO) Gas Sterilizers

How It Works: Chemical Alkylation

Ethylene oxide (EtO) sterilization is a low-temperature chemical process. EtO gas is a potent agent that disrupts the DNA of microorganisms, a process called alkylation, which prevents them from metabolizing or reproducing.

This process is effective at much lower temperatures, typically between 30°C and 60°C (86°F and 140°F), making it gentle on delicate materials.

Primary Applications

EtO is essential for sterilizing items that would be damaged by the high heat or moisture of an autoclave. This includes plastics, complex medical devices, electronics, catheters, and endoscopes.

Key Advantages

Its greatest advantage is broad material compatibility. The gas can also penetrate deep into the packaging and lumens of complex devices, ensuring comprehensive sterility where steam might not reach.

The Niche Solution: Dry Heat Sterilizers

How It Works: Oxidation and Dehydration

Dry heat sterilizers, essentially sophisticated ovens, use high temperatures over long exposure times to kill microorganisms. They operate at temperatures like 160-180°C (320-356°F) for one to two hours.

This method kills microbes primarily through oxidation of cellular components, a less efficient heat transfer mechanism than steam.

Primary Applications

Dry heat is used for materials that can tolerate high heat but are sensitive to moisture. Common applications include sterilizing powders, oils, some metal instruments (where it prevents rust), and glassware.

Key Advantages

The main benefit is its ability to sterilize in the complete absence of water, preventing corrosion and degradation of moisture-sensitive materials. The machines are also relatively simple and inexpensive to install.

Understanding the Trade-offs

Heat and Moisture vs. Material Damage

The autoclave is fast and highly effective, but its reliance on steam will destroy heat-sensitive plastics, melt delicate electronics, and dull sharp instruments over time. This is its single greatest limitation.

Speed vs. Complexity and Toxicity

While EtO is gentle on materials, it is a highly complex process. The gas is toxic and carcinogenic, requiring stringent safety protocols and a lengthy aeration period after the cycle to remove residual gas. This makes the total process time much longer than an autoclave cycle.

Efficiency vs. Application

Dry heat is far less efficient at transferring thermal energy than moist heat. This inefficiency necessitates significantly higher temperatures and longer cycle times, which can degrade materials like paper or cloth and limits its overall utility compared to steam.

Making the Right Choice for Your Application

Selecting the correct machine requires a clear understanding of your material's limitations and your operational needs.

- If your primary focus is speed and reliability for heat-stable items: The steam autoclave is the undisputed industry standard.

- If your primary focus is sterilizing heat- or moisture-sensitive devices: Ethylene oxide (EtO) is the necessary choice despite its operational complexity.

- If your primary focus is protecting moisture-sensitive materials that can tolerate high heat: A dry heat sterilizer offers a simple, effective solution.

Ultimately, selecting the correct sterilization machine is a matter of matching the method's physical properties to your material's specific tolerances.

Summary Table:

| Sterilization Method | How It Works | Best For | Key Advantage |

|---|---|---|---|

| Steam Sterilizer (Autoclave) | Pressurized steam at high temperature (e.g., 121°C) | Heat-stable, moisture-tolerant items (surgical instruments, glassware) | Fast, reliable, non-toxic, and cost-effective |

| Ethylene Oxide (EtO) Gas | Low-temperature chemical process (alkylation) | Heat- and moisture-sensitive materials (plastics, electronics, devices) | Gentle on delicate materials, penetrates complex packaging |

| Dry Heat Sterilizer | High temperatures for long periods (e.g., 160-180°C) | Moisture-sensitive items that can withstand heat (powders, oils, metal tools) | No moisture, preventing corrosion; simple operation |

Unsure which sterilization method is right for your laboratory's specific needs?

Selecting the correct equipment is critical for ensuring sterility without damaging your valuable instruments and materials. KINTEK specializes in providing reliable lab equipment and consumables, including autoclaves and sterilizers, to meet the precise demands of your laboratory workflows.

Our experts can help you navigate the trade-offs between speed, material compatibility, and safety to find the perfect solution for sterilizing everything from durable glassware to sensitive electronic components.

Contact us today to discuss your application and ensure absolute sterility for your critical processes.

Get a Personalized Consultation

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- What is the standard of autoclave? Mastering the 121°C Principle for True Sterilization

- What is the primary purpose and principle of autoclaving? The Definitive Guide to Sterilization

- What are the advantages of autoclaving sterilization? Achieve Unmatched Sterilization for Your Lab Equipment

- What is the purpose of using a high-temperature and high-pressure autoclave? Testing Cr2AlC Coatings for Nuclear Safety

- What is the function of a circulating loop system with a Hastelloy autoclave? Enhance PWR Corrosion Research Accuracy

- What is the use of autoclave in microbiology? Ensuring Sterile Conditions for Reliable Results

- What is the standard time for sterilization? Optimize Your Process for Safety and Efficiency

- Why are silver or platinum liners utilized in GaN synthesis? Protecting Purity and Autoclave Integrity