Blown film extrusion is a widely used manufacturing process in the plastics industry, particularly for producing thin films. This method offers several advantages, primarily due to its ability to create films with balanced mechanical properties, enhanced tensile strength, flexibility, and robustness. The process involves passing the material through various machines and traverse directions, ensuring uniformity and high-quality output. Below, we explore the key advantages of blown film extrusion in detail.

Key Points Explained:

-

Balanced Mechanical Properties

- Blown film extrusion ensures that the film has balanced mechanical properties, such as tensile strength, tear resistance, and puncture resistance.

- This balance is achieved because the film is stretched in both the machine direction (MD) and transverse direction (TD) during the process.

- Unlike simple extruded films, which may have uneven properties, blown films are more uniform, making them suitable for a wide range of applications.

-

Enhanced Tensile Strength

- The stretching process during blown film extrusion aligns the polymer molecules, resulting in improved tensile strength.

- This makes the film more durable and capable of withstanding stress, which is particularly important for applications like stretch films, packaging, and industrial uses.

-

Flexibility

- Blown films are highly flexible due to the molecular orientation achieved during the extrusion process.

- This flexibility allows the film to conform to various shapes and surfaces, making it ideal for packaging applications where tight wrapping is required.

-

Robustness

- The combination of balanced mechanical properties and enhanced tensile strength results in a robust film that can endure harsh handling and environmental conditions.

- This robustness is crucial for applications like agricultural films, construction films, and heavy-duty packaging.

-

Cost-Effectiveness

- Blown film extrusion is a cost-effective method for producing high-quality films.

- The process allows for high production rates and minimizes material waste, reducing overall manufacturing costs.

-

Versatility

- The blown film process can produce films of varying thicknesses, widths, and properties, making it suitable for a wide range of applications.

- It can also accommodate different types of polymers, including polyethylene (PE), polypropylene (PP), and others, further enhancing its versatility.

-

Uniform Thickness

- The bubble formation and cooling process in blown film extrusion ensure uniform thickness across the film.

- This uniformity is critical for applications requiring precise dimensions, such as medical packaging and food wrapping.

-

Improved Barrier Properties

- Blown films can be engineered to have excellent barrier properties against moisture, gases, and UV light.

- This is particularly beneficial for food packaging, where maintaining product freshness and shelf life is essential.

-

Ease of Customization

- The blown film process allows for easy customization of film properties, such as adding additives for UV resistance, anti-fogging, or anti-static properties.

- This adaptability makes it a preferred choice for specialized applications.

-

Sustainability

- Blown film extrusion can utilize recyclable materials, contributing to sustainable manufacturing practices.

- The process also generates less waste compared to other film production methods, aligning with environmental goals.

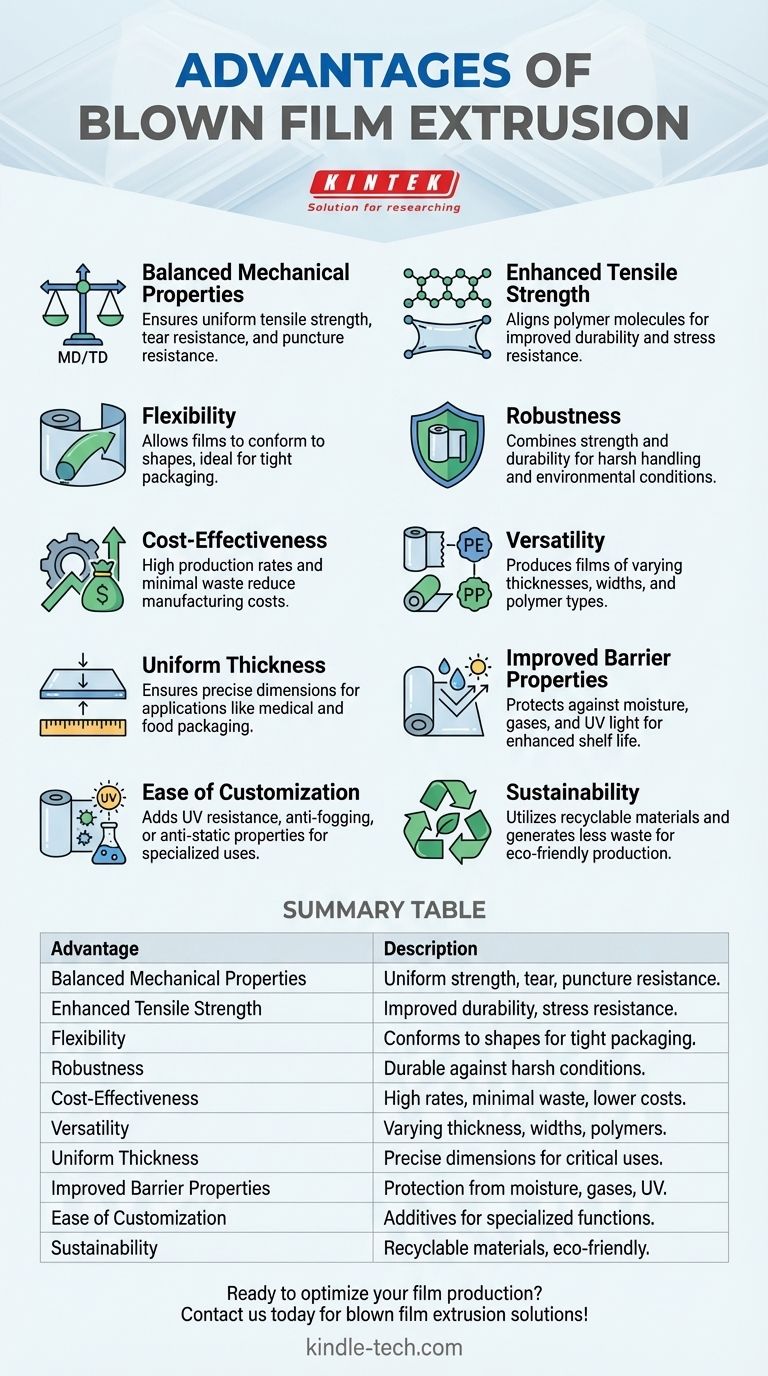

In summary, blown film extrusion offers numerous advantages, including balanced mechanical properties, enhanced tensile strength, flexibility, robustness, and cost-effectiveness. Its versatility, uniform thickness, improved barrier properties, and ease of customization make it a preferred choice for various industries. Additionally, its alignment with sustainability goals further enhances its appeal in modern manufacturing.

Summary Table:

| Advantage | Description |

|---|---|

| Balanced Mechanical Properties | Ensures uniform tensile strength, tear resistance, and puncture resistance. |

| Enhanced Tensile Strength | Aligns polymer molecules for improved durability and stress resistance. |

| Flexibility | Allows films to conform to shapes, ideal for tight packaging. |

| Robustness | Combines strength and durability for harsh handling and environmental conditions. |

| Cost-Effectiveness | High production rates and minimal waste reduce manufacturing costs. |

| Versatility | Produces films of varying thicknesses, widths, and polymer types. |

| Uniform Thickness | Ensures precise dimensions for applications like medical and food packaging. |

| Improved Barrier Properties | Protects against moisture, gases, and UV light for enhanced shelf life. |

| Ease of Customization | Adds UV resistance, anti-fogging, or anti-static properties for specialized uses. |

| Sustainability | Utilizes recyclable materials and generates less waste for eco-friendly production. |

Ready to optimize your film production? Contact us today to learn more about blown film extrusion solutions!

Visual Guide

Related Products

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Anti-Cracking Press Mold for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- What is the meaning of blowing film? A Guide to Biaxial Orientation and Stronger Plastic Films

- What are the disadvantages of the extrusion process? High Costs and Geometric Limits Explained

- What is the process of calendering in plastic processing? A Guide to High-Volume Film & Sheet Production

- What is the cost of blown film extrusion? From $20K to High-End Systems

- What is the process of calendering? A Guide to High-Volume Plastic Film Production