The primary advantages of a two-high rolling mill are its simple design, lower operational costs, and robust performance, particularly in hot rolling applications. This configuration features durable, long-lasting work rolls that are easier to maintain and change compared to more complex mill designs.

While often overshadowed by more advanced configurations, the two-high mill's strength lies in its fundamental simplicity. This makes it an exceptionally cost-effective and reliable solution for initial, heavy reduction passes where durability is more critical than precision.

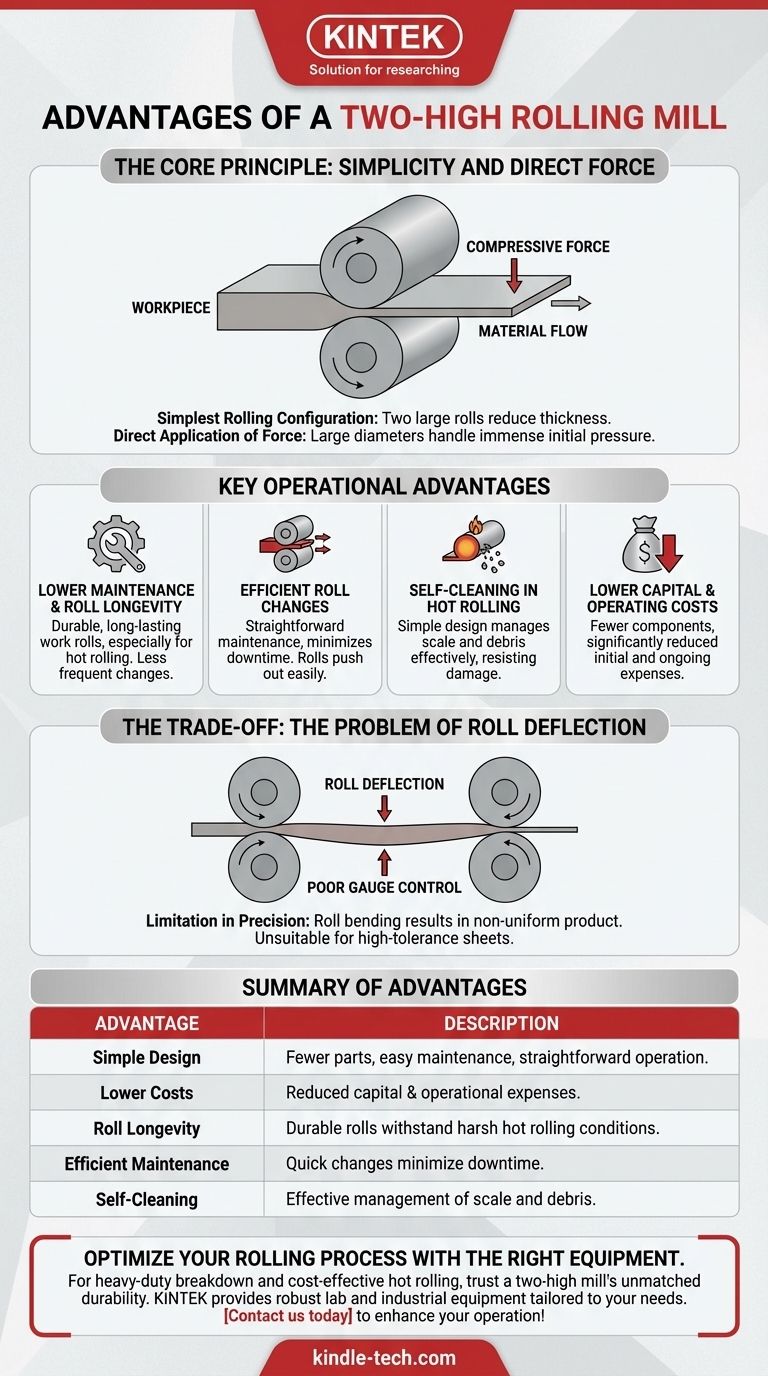

The Core Principle: Simplicity and Direct Force

A rolling mill's purpose is to reduce the thickness of a material or impart a specific shape through compressive force. The two-high mill is the most foundational design for achieving this.

The Simplest Rolling Configuration

A two-high mill consists of two large-diameter rolls rotating in opposite directions. The material, or workpiece, is passed between them, and the force exerted by the rolls reduces its thickness.

This simple construction, with fewer moving parts than other mill types, is the source of both its greatest strengths and its primary limitations.

Direct Application of Force

The entire compressive force is applied directly through these two work rolls. Their large diameter provides the necessary strength and rigidity to handle the immense pressures required for initial material breakdown.

Key Operational Advantages

In specific contexts, particularly hot rolling and initial processing stages, the two-high mill provides distinct benefits over more complex systems like the four-high mill.

Lower Maintenance and Roll Longevity

The large, robust work rolls in a two-high mill are inherently durable. In hot rolling, they do not need to be replaced as frequently as the smaller, more delicate work rolls found in a four-high setup.

Efficient Roll Changes

The design facilitates straightforward maintenance. When a roll change is required, the rolls can often be pushed out directly from the side of the mill housing, minimizing downtime and getting the operation back online quickly.

Self-Cleaning in Hot Rolling

During hot rolling, the material is covered in scale (an oxide layer) that flakes off during processing. The simple, two-roll setup is less susceptible to damage from this debris and is considered "self-cleaning," a key advantage in this harsh environment.

Lower Capital and Operating Costs

With fewer components—no backup rolls, complex bearings, or support systems—the initial investment for a two-high mill is significantly lower. This simplicity translates directly to reduced ongoing maintenance costs.

Understanding the Trade-offs: Where Two-High Mills Fall Short

To truly understand the value of a two-high mill, you must also understand its limitations. Its simplicity introduces a critical engineering challenge that makes it unsuitable for many modern applications.

The Problem of Roll Deflection

Under the immense pressure of rolling, the rolls will bend slightly in the middle, away from the workpiece. This phenomenon is known as roll deflection.

Because the rolls in a two-high mill are only supported at their ends, this deflection is unavoidable.

Impact on Precision and Gauge Control

Roll deflection results in a finished product that is thicker in the center and thinner at the edges. This lack of uniformity, or poor gauge control, makes the two-high mill a poor choice for producing finished plates or sheets that require tight dimensional tolerances.

The Rise of the Four-High Mill

This fundamental limitation is precisely why the four-high mill was invented. In a four-high mill, two small-diameter work rolls are supported by two much larger backup rolls, which prevent deflection and enable the production of highly uniform, flat material.

Making the Right Choice for Your Goal

The decision to use a two-high mill is entirely dependent on the specific stage of the manufacturing process and the desired outcome for the material.

- If your primary focus is initial breakdown or roughing passes: The two-high mill's durability, low cost, and simple maintenance make it the ideal choice for heavy, initial reductions of ingots and slabs.

- If your primary focus is producing finished products with high precision: The two-high mill is unsuitable due to roll deflection; a four-high or cluster mill is necessary to achieve the required flatness and tolerance.

- If your primary focus is cost-effectiveness for non-precision work: The two-high mill remains a relevant and highly effective tool for applications where absolute gauge control is not the priority.

Understanding this core trade-off between the two-high mill's robust simplicity and the precision of more complex designs is key to optimizing any rolling operation.

Summary Table:

| Advantage | Description |

|---|---|

| Simple Design | Fewer moving parts, easier maintenance, and straightforward operation. |

| Lower Costs | Reduced capital investment and operational expenses compared to complex mills. |

| Roll Longevity | Large, durable work rolls withstand harsh conditions, especially in hot rolling. |

| Efficient Maintenance | Quick roll changes minimize downtime, boosting productivity. |

| Self-Cleaning | Effective in hot rolling environments where scale debris is present. |

Optimize your rolling process with the right equipment. For heavy-duty material breakdown and cost-effective hot rolling, a two-high mill offers unmatched durability and simplicity. At KINTEK, we specialize in providing robust lab and industrial equipment tailored to your specific needs. Whether you're processing metals or other materials, our expertise ensures you get the most efficient and reliable solution. Contact us today to discuss how a two-high mill can enhance your operation's performance and reduce costs!

Visual Guide

Related Products

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Jar Mill with Agate Grinding Jar and Balls

People Also Ask

- What is the use of two roll mill? Essential for Polymer Mixing, R&D, and Quality Control

- What is the difference between Banbury and internal mixer? Understanding Rotor Design for Better Mixing

- What is a two-high roll mill? Master Precise Material Compounding and Testing

- What are the advantages of a two roll mill? Achieve Superior Polymer Mixing & Quality Control

- What is a rubber mixing mill used for? Transforming Raw Rubber into High-Performance Compounds