In food engineering, evaporators are primarily categorized by the method they use to expose the liquid food to a heating surface. The main designs include falling film, rising film, forced circulation, and agitated thin film evaporators, each suited for different product characteristics like viscosity and heat sensitivity. The goal is always to remove water (as steam) efficiently while minimizing thermal damage to the product's flavor, color, and nutritional value.

The most critical factor in selecting an evaporator is not the equipment's raw power, but its specific design's suitability for your product's unique properties. The choice is a direct trade-off between processing efficiency, energy cost, and the preservation of the food's final quality.

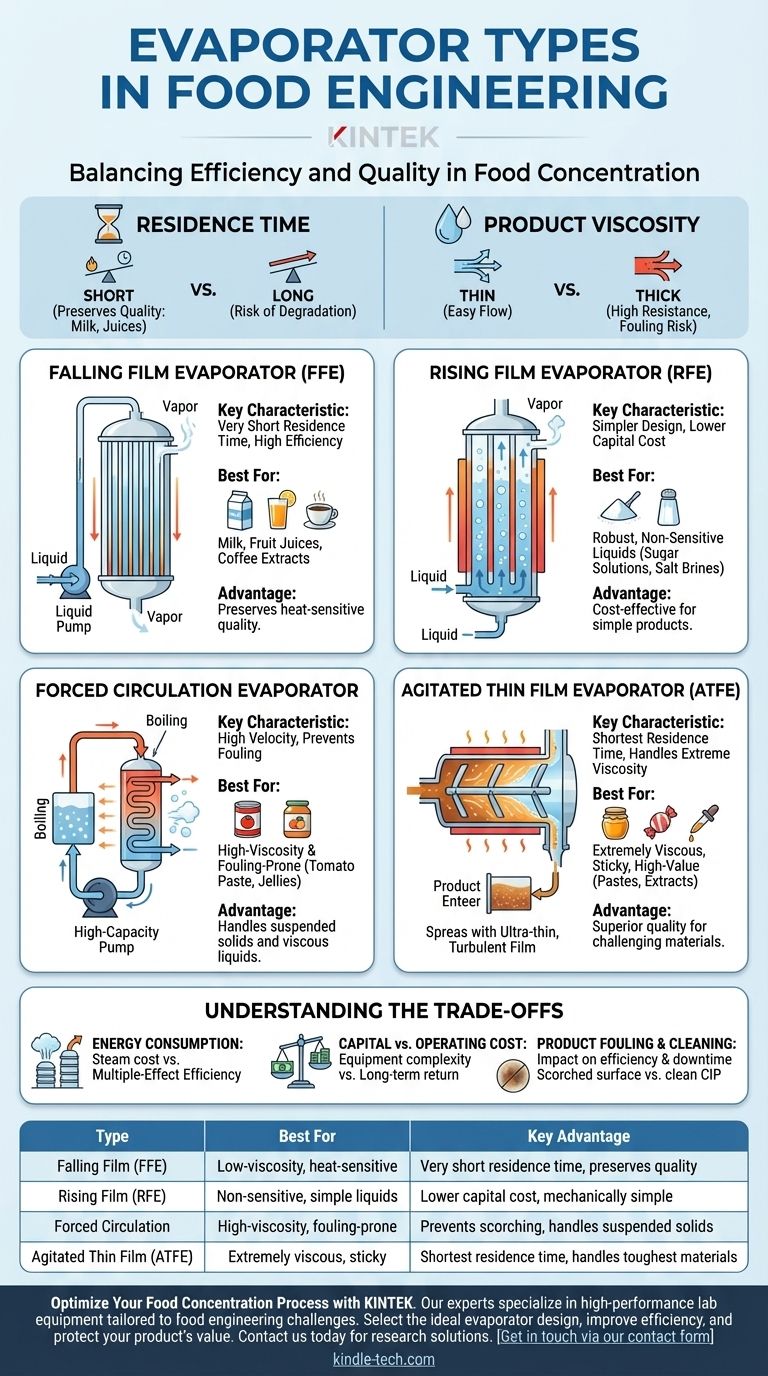

The Core Principle: Balancing Efficiency and Quality

Evaporation in food processing is a delicate balancing act. You are applying heat to drive off water, but that same heat can degrade the very product you are trying to concentrate.

Think of reducing a sauce in a pot at home. If you use high heat, it reduces quickly but risks scorching the bottom and creating burnt flavors. If you use low heat, it preserves the flavor but takes a very long time and uses more energy. Industrial evaporators are engineered to solve this problem at a massive scale.

Key Factor: Residence Time

Residence time is the amount of time the food product spends inside the evaporator being exposed to heat.

For heat-sensitive products like milk, fruit juices, or coffee extract, a short residence time is critical to prevent cooked flavors, browning (Maillard reaction), and vitamin loss.

Key Factor: Product Viscosity

Viscosity, or the thickness of the liquid, dictates how easily it will flow and transfer heat.

As water is removed, the product becomes more concentrated and its viscosity increases significantly. An evaporator must be able to handle this final viscosity without compromising flow or burning the product onto the heat transfer surfaces.

Common Evaporator Designs Explained

Each evaporator design represents a different strategy for managing residence time, heat transfer, and viscosity.

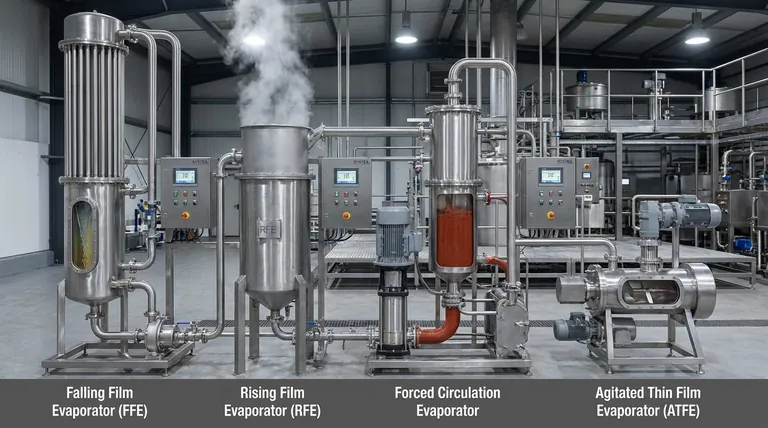

Falling Film Evaporators (FFEs)

In an FFE, the liquid is pumped to the top of a bundle of long vertical tubes. It flows downwards along the inside walls of these heated tubes as a thin, continuous film.

This design creates a large surface area for heat transfer, leading to rapid evaporation. Because the film moves quickly through the tubes via gravity, FFEs offer a very short residence time, making them ideal for heat-sensitive, low-viscosity liquids.

Best for: Milk, fruit juices, coffee extracts.

Rising Film Evaporators (RFEs)

The RFE is structurally similar to the FFE, but the liquid is fed into the bottom of the heated tubes. As the liquid boils, the vapor bubbles that form create a "vapor lift," pushing the remaining liquid upwards and out the top.

This design is mechanically simpler and generally has a lower capital cost. However, the residence time is longer and less controlled than in an FFE, increasing the risk of thermal degradation for sensitive products.

Best for: Robust, non-sensitive liquids like sugar solutions or salt brines where initial cost is a major factor.

Forced Circulation Evaporators

This design is built for challenging products. A high-capacity pump is used to force the liquid at high velocity through a heat exchanger. The intense flow velocity creates high turbulence, which is excellent for heat transfer and, most importantly, prevents suspended solids from settling and minimizes fouling on the heat surfaces.

Because boiling does not occur within the heat exchanger itself (due to hydrostatic pressure), this system can handle highly viscous liquids and those with suspended solids without scorching.

Best for: Tomato paste, fruit purees, jellies, and other high-viscosity or fouling-prone products.

Agitated Thin Film Evaporators (ATFEs)

Also known as wiped-film evaporators, these are the most specialized and advanced design for extremely challenging products. The product enters a heated cylinder where a set of rotating blades or wipers continuously spread it into an ultra-thin, turbulent film against the wall.

This mechanical agitation provides exceptional heat transfer and allows the system to process extremely viscous or sticky materials. Residence time is measured in seconds, making it perfect for the most heat-sensitive, high-value products.

Best for: High-concentration fruit pastes, confectionery masses, and pharmaceutical-grade extracts.

Understanding the Trade-offs

Choosing an evaporator is an economic and technical decision with clear trade-offs.

Energy Consumption

Evaporation is one of the most energy-intensive unit operations in food processing. The cost of generating steam is a significant operational expense.

To combat this, plants often use multiple-effect evaporation. In this setup, the vapor produced in the first evaporator ("effect") is used as the heating medium for the second effect, which operates at a lower pressure and temperature. This dramatically improves thermal efficiency but increases the initial capital investment.

Capital Cost vs. Operating Cost

There is a direct relationship between equipment complexity and cost. A simple Rising Film Evaporator has a low upfront cost, but may be inefficient or unsuitable for high-value products.

An Agitated Thin Film Evaporator has a very high capital cost, but its ability to produce a superior quality concentrate from a difficult material may provide a return on that investment through a premium final product.

Product Fouling and Cleaning

When a product burns or settles onto the heating surfaces, it's called fouling. Fouling insulates the surface, drastically reducing heat transfer efficiency and requiring shutdown for cleaning (CIP).

Forced circulation evaporators are explicitly designed to minimize fouling, reducing downtime and maintaining consistent performance, a critical factor for products like tomato concentrates.

Making the Right Choice for Your Product

Your final decision must be guided by the nature of your food product and your business goals.

- If your primary focus is low-viscosity, heat-sensitive liquids (like milk or juice): Your best choice is a Falling Film or Plate Evaporator to preserve quality with excellent efficiency.

- If your primary focus is high-viscosity liquids or slurries prone to fouling (like tomato paste): You must use a Forced Circulation Evaporator to ensure continuous operation and prevent scorching.

- If your primary focus is extremely viscous, sticky, and valuable materials (like high-end confectionery): An Agitated Thin Film Evaporator is the only design that can handle the product while protecting its quality.

- If your primary focus is low capital cost for a simple, non-sensitive liquid: A Rising Film Evaporator is a viable starting point.

By aligning the evaporator's fundamental design with your product's specific characteristics, you ensure both efficient water removal and the preservation of final quality.

Summary Table:

| Evaporator Type | Best For (Product Characteristics) | Key Advantage |

|---|---|---|

| Falling Film (FFE) | Low-viscosity, heat-sensitive liquids (milk, juice) | Very short residence time, preserves quality |

| Rising Film (RFE) | Non-sensitive, simple liquids (sugar solutions) | Lower capital cost, mechanically simple |

| Forced Circulation | High-viscosity, fouling-prone liquids (tomato paste) | Prevents scorching, handles suspended solids |

| Agitated Thin Film (ATFE) | Extremely viscous, sticky, high-value products | Shortest residence time, handles toughest materials |

Optimize Your Food Concentration Process with KINTEK

Choosing the right evaporator is critical to balancing efficiency, cost, and the final quality of your concentrated food product. Our experts at KINTEK specialize in providing high-performance lab equipment and consumables tailored to the unique challenges of food engineering.

We can help you:

- Select the ideal evaporator design for your specific product's viscosity and heat sensitivity.

- Improve process efficiency and reduce energy consumption.

- Protect your product's flavor, color, and nutritional value with equipment designed for minimal thermal degradation.

Contact us today to discuss your laboratory's evaporation needs and discover how our solutions can enhance your research and development. Get in touch via our contact form!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Ceramic Evaporation Boat Set Alumina Crucible for Laboratory Use

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition