At their core, optical coatings are microscopically thin layers of material applied to an optical surface, like a lens or mirror, to change how it reflects, transmits, or absorbs light. The primary types are anti-reflection (AR) coatings to maximize light throughput, high-reflection (HR) or dielectric mirror coatings to create highly efficient mirrors, and various filter coatings that selectively pass or block specific wavelengths of light.

Optical coatings are not just simple layers; they are precision-engineered structures that manipulate light waves through a principle called thin-film interference. Understanding your specific goal—whether it's maximizing transmission, creating a perfect reflection, or isolating a color—is the key to selecting the correct coating technology.

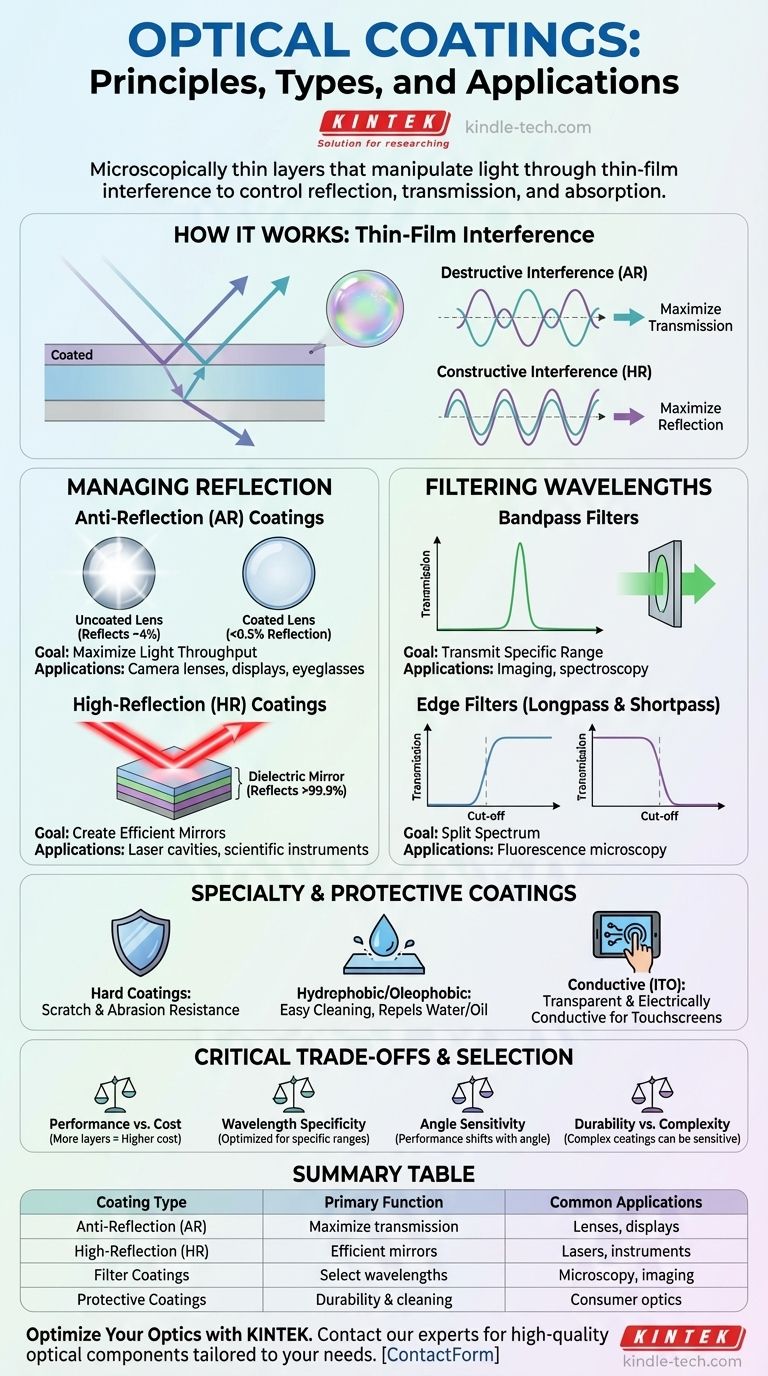

How Optical Coatings Work: The Principle of Interference

The function of most advanced optical coatings is not based on the bulk properties of the material, but on an optical phenomenon called thin-film interference. This is the same effect that creates the rainbow shimmer on a soap bubble or a patch of oil on water.

The Role of Material and Thickness

When light strikes the boundary between two materials with different refractive indices (e.g., air and the coating), some light reflects and some passes through. An optical coating adds more boundaries—one at the top of the coating and one at the bottom.

By precisely controlling the thickness of each layer (often to within a quarter of a wavelength of light) and the refractive index of the materials used, engineers can control how the light waves reflecting from these different surfaces interfere with each other.

Constructive vs. Destructive Interference

Destructive interference occurs when the reflected light waves are out of phase and cancel each other out. This is the goal of an anti-reflection coating.

Constructive interference occurs when the reflected waves are in phase and reinforce each other. This is the principle behind a high-reflection coating.

Coatings That Manage Reflection

These coatings are designed to either eliminate or maximize reflection at a surface.

Anti-Reflection (AR) Coatings

The goal of an AR coating is to maximize the transmission of light through an optical element by minimizing surface reflections. Uncoated glass reflects about 4% of light per surface.

A single-layer AR coating can reduce this reflection significantly, while a modern broadband multi-layer AR coating can reduce reflection to less than 0.5% across the entire visible spectrum. These are essential for applications like camera lenses, eyeglasses, and display screens where clarity and brightness are paramount.

High-Reflection (HR) Coatings (Dielectric Mirrors)

The goal of an HR coating is to maximize reflection. By stacking dozens of alternating layers of high and low refractive index materials, these coatings can create a mirror that reflects over 99.9% of light at a specific wavelength.

Unlike a simple metallic mirror (like aluminum or silver) which absorbs some light, a dielectric mirror is almost lossless, making it critical for high-power applications like laser cavities.

Coatings That Filter Wavelengths

Filter coatings are designed to selectively transmit some wavelengths (colors) of light while blocking others.

Bandpass Filters

A bandpass filter is designed to transmit a specific, narrow range of wavelengths while blocking all others. For example, a filter might only let green light between 520 and 560 nanometers pass through. These are used extensively in scientific and medical imaging.

Edge Filters (Longpass and Shortpass)

Edge filters divide the spectrum into a transmitted region and a blocked region.

A shortpass filter transmits wavelengths shorter than a certain "cut-off" point and blocks longer ones. A longpass filter does the opposite, transmitting longer wavelengths and blocking shorter ones. These are fundamental tools in applications like fluorescence microscopy.

Specialty and Protective Coatings

Beyond purely optical performance, many coatings add durability and functionality.

Hard Coatings

These are typically applied to polymer (plastic) lenses or other soft surfaces to provide scratch and abrasion resistance, significantly extending the life of the optic.

Hydrophobic and Oleophobic Coatings

These coatings create a surface that repels water (hydrophobic) and oil (oleophobic). This makes the optic much easier to clean, as seen on modern smartphone screens and high-end eyeglasses.

Conductive Coatings

Transparent conductive coatings, most commonly Indium Tin Oxide (ITO), are both optically clear and electrically conductive. They are the enabling technology for touch screens, heated windows in aircraft, and EMI shielding on displays.

Understanding the Critical Trade-offs

Choosing a coating is never a simple matter of "best." It is always a balance of competing requirements.

Performance vs. Cost

A simple, single-layer magnesium fluoride AR coating is inexpensive. A 50-layer, high-power laser mirror with extremely tight tolerances is exceptionally expensive. More layers and more precise control always increase cost.

Wavelength Specificity

Most high-performance coatings are optimized for a specific wavelength range. An AR coating designed for visible light may perform very poorly in the infrared (IR). A laser mirror is often designed for only a single wavelength.

Angle of Incidence Sensitivity

The performance of an interference coating changes with the angle at which light strikes it. A coating designed for light hitting straight-on (0° angle of incidence) will have its performance characteristics shift to shorter wavelengths as the angle increases. This must be accounted for in the system design.

Durability vs. Complexity

Some of the most complex multi-layer coatings can be sensitive to environmental factors like humidity, temperature shifts, or improper cleaning. There is often a trade-off between peak optical performance and ruggedness for field use.

Selecting the Right Coating for Your Application

Your choice must be driven by the primary goal of your optical system.

- If your primary focus is maximizing light throughput and clarity: You need a broadband anti-reflection (AR) coating, which is standard for camera lenses, binoculars, and displays.

- If your primary focus is creating a highly efficient mirror: You need a high-reflection (HR) dielectric coating designed for your specific wavelength and angle of use, common in lasers and specialized instruments.

- If your primary focus is isolating or blocking specific colors: You need a bandpass, shortpass, or longpass filter coating tailored to the exact wavelengths you need to manage.

- If your primary focus is durability and ease of use: You should prioritize hard coatings for scratch resistance and hydrophobic/oleophobic coatings for easy cleaning on consumer-facing products.

Ultimately, a well-chosen optical coating transforms a simple piece of glass into a high-performance component engineered for a specific task.

Summary Table:

| Coating Type | Primary Function | Common Applications |

|---|---|---|

| Anti-Reflection (AR) | Maximize light transmission | Camera lenses, eyeglasses, displays |

| High-Reflection (HR) | Create efficient mirrors | Laser systems, scientific instruments |

| Filter Coatings | Selectively pass/block wavelengths | Microscopy, imaging, spectroscopy |

| Protective Coatings | Add durability & easy cleaning | Smartphone screens, consumer optics |

Ready to enhance your optical system's performance? The right coating is critical for achieving clarity, efficiency, and durability in your lab equipment. At KINTEK, we specialize in providing high-quality lab equipment and consumables, including precision optical components tailored to your specific wavelength and application needs. Our experts can help you select the perfect coating to maximize light throughput, create highly efficient mirrors, or isolate specific wavelengths for your research or instrumentation.

Let's optimize your optics together. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Infrared High Resistance Single Crystal Silicon Lens

- Rotating Platinum Disk Electrode for Electrochemical Applications

People Also Ask

- What is plasma sputtering deposition technique? Achieve Ultra-Thin, High-Purity Coatings

- What do the optical properties of thin film depend on? Mastering Material, Thickness, and Process

- Which coating is best for lenses? Build Custom Glasses for Your Vision and Lifestyle

- What are the benefits of diamond ceramic coating? Unlock Maximum Protection and Longevity for Your Vehicle

- Is CVD diamond a good investment? The Truth About Lab-Grown Diamond Value

- What are the deposition materials? A Guide to Metals, Ceramics, and Compounds for Thin Films

- Are carbon nanotubes stronger than graphene? Choosing the Right Carbon Nanomaterial for Your Application

- What is CVD metal? The Truth About High-Performance Surface Coatings