Fluidized bed reactors (FBRs) present significant operational challenges stemming directly from their dynamic and turbulent nature. While prized for temperature control, their primary disadvantages include severe erosion of internal components, unpredictable fluid dynamics that hinder reaction efficiency, the constant loss of fine particles, and high energy consumption required to maintain fluidization.

While FBRs offer unparalleled heat and mass transfer, their primary disadvantages are a direct consequence of their chaotic, particle-filled environment. These challenges—including mechanical wear, inefficient reactant contacting, and material loss—require significant and costly engineering systems to manage effectively.

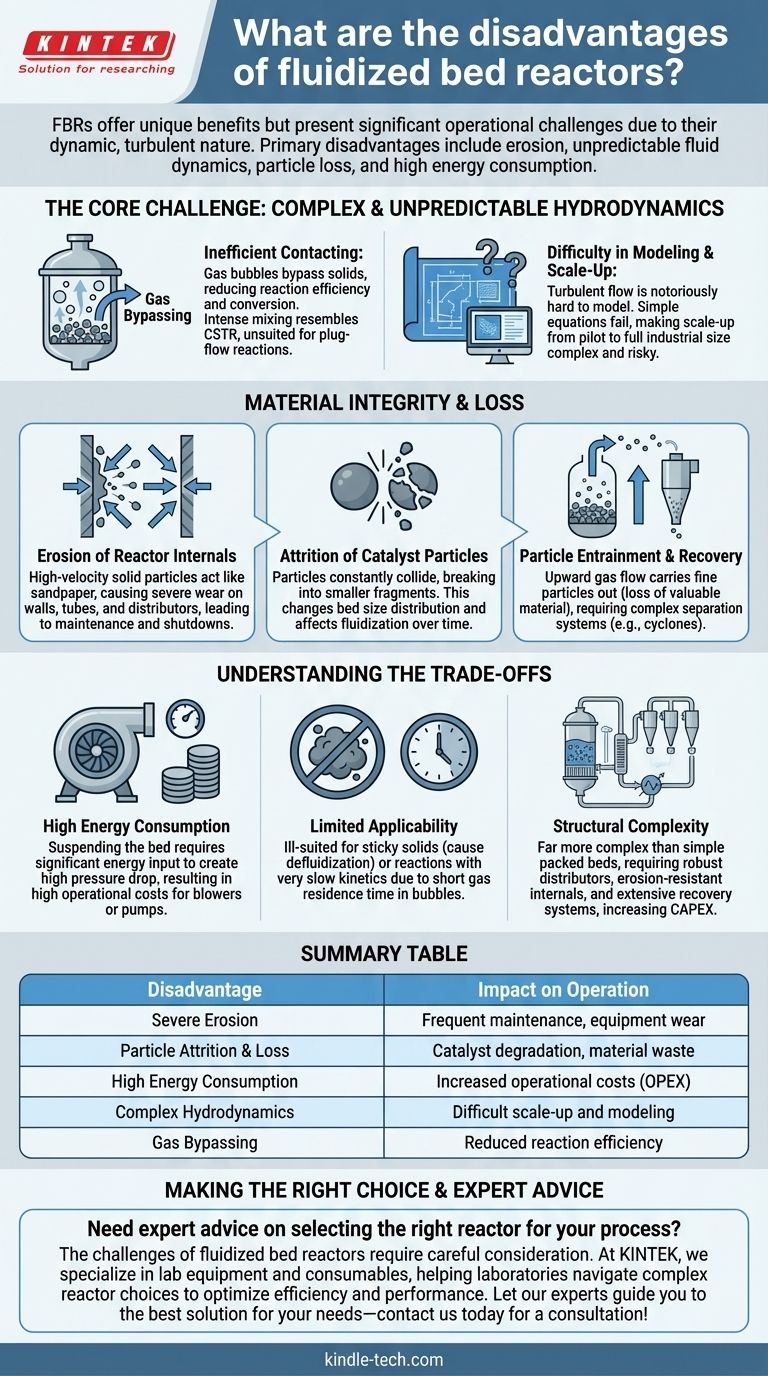

The Core Challenge: Complex and Unpredictable Hydrodynamics

The "fluid-like" behavior of the solid particles is both the FBR's main advantage and the source of its greatest weaknesses. This environment is far from ideal and difficult to control with precision.

Inefficient Contacting and Back-Mixing

In many FBRs, especially bubbling-bed reactors, much of the gas can travel from the bottom to the top inside large bubbles. This gas bypassing means the reactant has very limited contact with the solid catalyst particles, drastically reducing reaction efficiency and conversion. The intense mixing also creates a state closer to a CSTR (Continuously Stirred-Tank Reactor), which is unsuitable for reactions that require the orderly progression of a plug-flow system to maximize yield.

Difficulty in Modeling and Scale-Up

The complex, turbulent flow of gas and solids is notoriously difficult to model accurately. Simple reactor design equations do not apply. This uncertainty complicates performance prediction and makes scaling up from a pilot plant to a full-sized industrial reactor a significant engineering challenge. A design that works at a small scale may fail at a large scale as bubble behavior and mixing patterns change unpredictably.

Material Integrity and Loss

The constant, high-velocity motion of abrasive solid particles creates two major mechanical problems: wear on the equipment and degradation of the particles themselves.

Erosion of Reactor Internals

Solid particles, especially hard catalysts, act like sandpaper at high velocity. They cause severe erosion on the reactor walls, heat exchanger tubes, gas distributor plates, and downstream piping. This continuous wear leads to frequent maintenance, costly shutdowns, and potential equipment failure.

Attrition of Catalyst Particles

The particles don't just hit the reactor walls; they constantly collide with each other. This process, known as attrition, breaks the particles down into smaller fragments and dust. Attrition fundamentally changes the size distribution of the bed, which can alter its fluidization properties over time.

Particle Entrainment and Recovery

The upward flow of gas inevitably carries the smallest particles (fines), whether from attrition or the original feed, out of the reactor. This particle entrainment represents a direct loss of valuable catalyst or reactant. To mitigate this, complex and expensive separation systems, such as one or more stages of cyclones, must be installed downstream. Even with these systems, some loss of the finest particles is unavoidable.

Understanding the Trade-offs

Choosing an FBR means accepting a set of operational burdens in exchange for its unique benefits. These trade-offs often revolve around operational cost and process suitability.

High Energy Consumption

Suspending the entire bed of solids requires a significant and continuous input of energy. The gas or liquid must be forced through the distributor and the bed itself, creating a high pressure drop. This translates directly into high operational costs from the large blowers or pumps needed to run the reactor.

Limited Applicability

FBRs are not a universal solution. They are particularly ill-suited for processes involving sticky or agglomerating solids, which can clump together and cause the bed to "defluidize," leading to a complete process shutdown. They are also a poor choice for reactions that have very slow kinetics, as the short residence time of the gas in the bubbles prevents adequate conversion.

Structural Complexity

Compared to a simple packed-bed reactor, an FBR system is far more complex. It requires robust distributor plates to ensure even fluidization, internal heat exchangers that can withstand erosion, and an extensive external system of cyclones and filters for particle recovery. This all adds to the capital cost (CAPEX) of the unit.

Making the Right Choice for Your Process

The decision to use an FBR must be weighed carefully against its inherent drawbacks. Your primary process goal is the most important factor.

- If your primary focus is managing a highly exothermic reaction: The FBR's elite temperature control may be worth the engineering effort needed to manage erosion and particle loss.

- If your primary focus is achieving the highest possible reactant conversion: The gas bypassing and back-mixing in an FBR are major liabilities; a fixed-bed or tubular reactor will likely provide better performance.

- If your primary focus is using a fragile or expensive catalyst: The high rates of attrition and entrainment make FBRs a risky and potentially costly choice unless you invest heavily in robust particle design and recovery systems.

Ultimately, the decision to use a fluidized bed reactor is an engineering trade-off between its superior transfer capabilities and the significant costs required to mitigate its inherent physical complexities.

Summary Table:

| Disadvantage | Impact on Operation |

|---|---|

| Severe Erosion | Frequent maintenance, equipment wear |

| Particle Attrition & Loss | Catalyst degradation, material waste |

| High Energy Consumption | Increased operational costs (OPEX) |

| Complex Hydrodynamics | Difficult scale-up and modeling |

| Gas Bypassing | Reduced reaction efficiency |

Need expert advice on selecting the right reactor for your process? The challenges of fluidized bed reactors require careful consideration of your specific application. At KINTEK, we specialize in lab equipment and consumables, helping laboratories navigate complex reactor choices to optimize efficiency and performance. Let our experts guide you to the best solution for your needs—contact us today for a consultation!

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- What role does an autoclave play in simulating PWR conditions? Advanced Material Validation for Nuclear Safety

- What is the purpose of using high-purity argon gas in a high-pressure reactor? Ensure Precise Corrosion Test Data

- What is the purpose of using a high-temperature hydrothermal reactor? Enhance Iodine@Activated Carbon Cathode Synthesis

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield