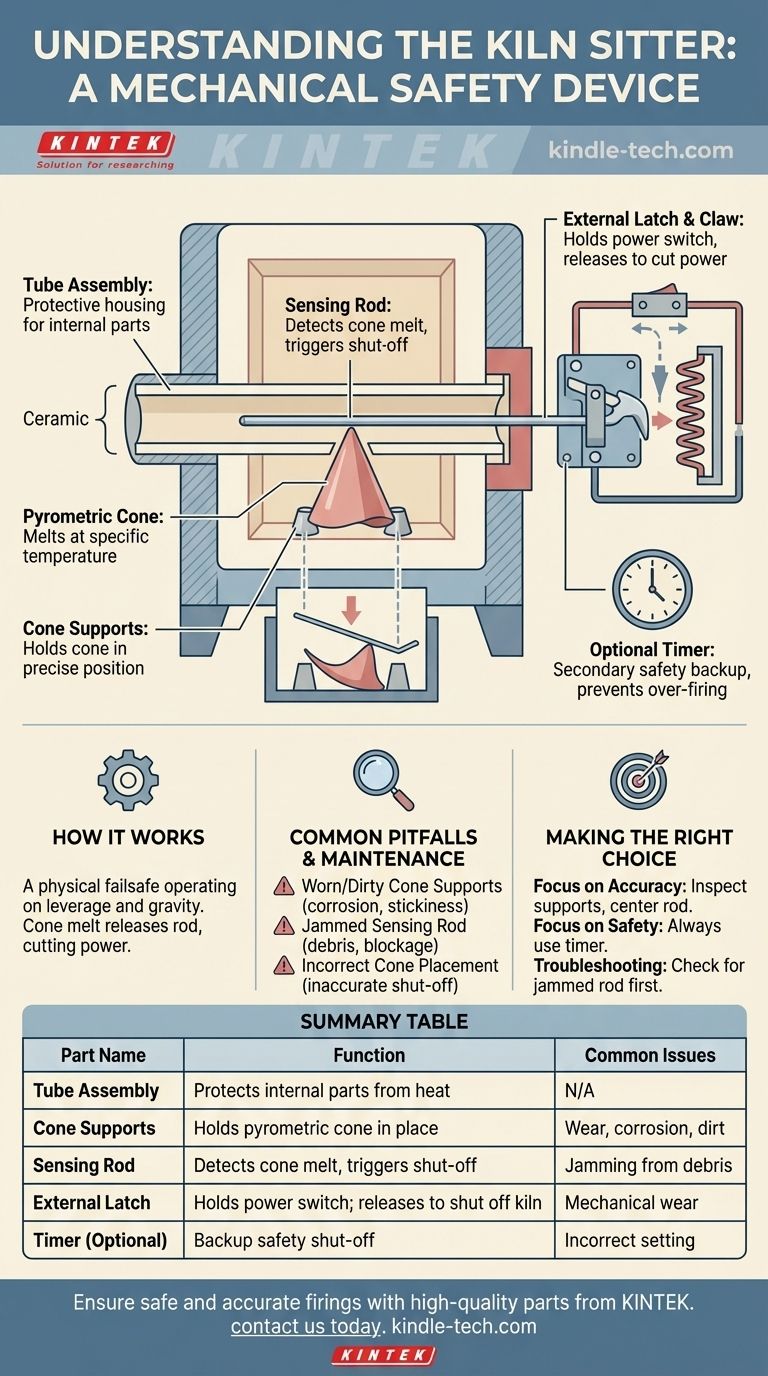

At its core, a kiln sitter is a simple mechanical device with three essential components: the tube assembly, the cone supports, and the sensing rod. This mechanism acts as a crucial safety shut-off for your kiln, triggered by the melting of a pyrometric cone at a specific temperature. Many models also include a timer as a backup safety feature.

A kiln sitter is not an electronic controller but a physical failsafe. Understanding how its simple, interconnected parts work together is the key to ensuring your firings shut off reliably and your work is protected.

How the Kiln Sitter's Parts Work in Concert

A kiln sitter operates on a basic principle of leverage and gravity. A small, specially formulated pyrometric cone is the key. When this cone softens at its designated temperature, it allows a rod to drop, which triggers a switch to cut power to the kiln.

The Tube Assembly

The tube assembly is the housing for the mechanism. This hollow ceramic tube passes through a hole in the kiln wall, protecting the internal metal components from the kiln's intense heat.

The Cone Supports

Located on the inside of the kiln, the cone supports are two small metal prongs. They are designed to hold the small pyrometric cone in a precise horizontal position. The integrity of these supports is critical for an accurate firing.

The Sensing Rod

The sensing rod is a thin metal rod that sits inside the tube assembly. Its tip rests directly on top of the pyrometric cone that is held by the supports. The other end of the rod is connected to the external trigger mechanism.

The External Latch and Claw

Outside the kiln, the sensing rod engages a weighted claw or latch mechanism. When the kiln is on, this latch holds the power switch in the "on" position. As the cone inside softens and sags, the sensing rod drops slightly, releasing the claw and allowing the switch to fall, cutting power to the heating elements.

The Optional Timer

Many kiln sitters include a timer. This is a secondary safety device. You set it for slightly longer than your expected firing time. If the cone fails to melt and shut off the kiln for any reason, the timer will cut the power, preventing a catastrophic over-firing.

Common Pitfalls and Maintenance Checks

Because it's a mechanical system, a kiln sitter requires periodic inspection and maintenance to function correctly. Neglecting this can lead to failed firings.

Worn or Dirty Cone Supports

Over time, cone supports can corrode or become coated with kiln wash. This can cause the cone to stick or sit improperly, leading to an inaccurate or late shut-off. They should be kept clean and replaced if they become pitted or bent.

A Jammed Sensing Rod

Debris, such as bits of kiln wash or clay, can fall into the tube assembly and prevent the sensing rod from dropping freely. This is a common cause of kiln over-firings. You should periodically check that the rod moves without resistance.

Incorrect Cone Placement

The pyrometric cone must be placed correctly on the supports. If it is pushed too far back or not centered, it will not trigger the shut-off at the correct temperature. Always follow the manufacturer's placement guide.

Making the Right Choice for Your Firing

Your goal determines how you should approach your kiln sitter's use and maintenance.

- If your primary focus is firing accuracy: Always inspect your cone supports before a firing and ensure the sensing rod rests perfectly in the center of the cone.

- If your primary focus is safety: Always use the timer as a non-negotiable backup to protect your kiln and studio in case of mechanical failure.

- If you are troubleshooting a failed shut-off: Before assuming a major part is broken, check for the most common issue—a sensing rod that is unable to move freely within its tube.

Mastering these simple components gives you direct control over the safety and success of every firing.

Summary Table:

| Part Name | Function | Common Issues |

|---|---|---|

| Tube Assembly | Protects internal parts from heat | N/A |

| Cone Supports | Holds pyrometric cone in place | Wear, corrosion, dirt |

| Sensing Rod | Detects cone melt, triggers shut-off | Jamming from debris |

| External Latch | Holds power switch; releases to shut off kiln | Mechanical wear |

| Timer (Optional) | Backup safety shut-off | Incorrect setting |

Ensure your kiln operates safely and accurately with reliable parts from KINTEK. Whether you need replacement cone supports, sensing rods, or other kiln sitter components, our high-quality lab equipment and consumables are designed for precision and durability. Don't risk a failed firing—contact us today to get the right parts for your kiln's needs!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 308L Precision Ultra Low Temperature Freezer for Laboratory Applications

People Also Ask

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker