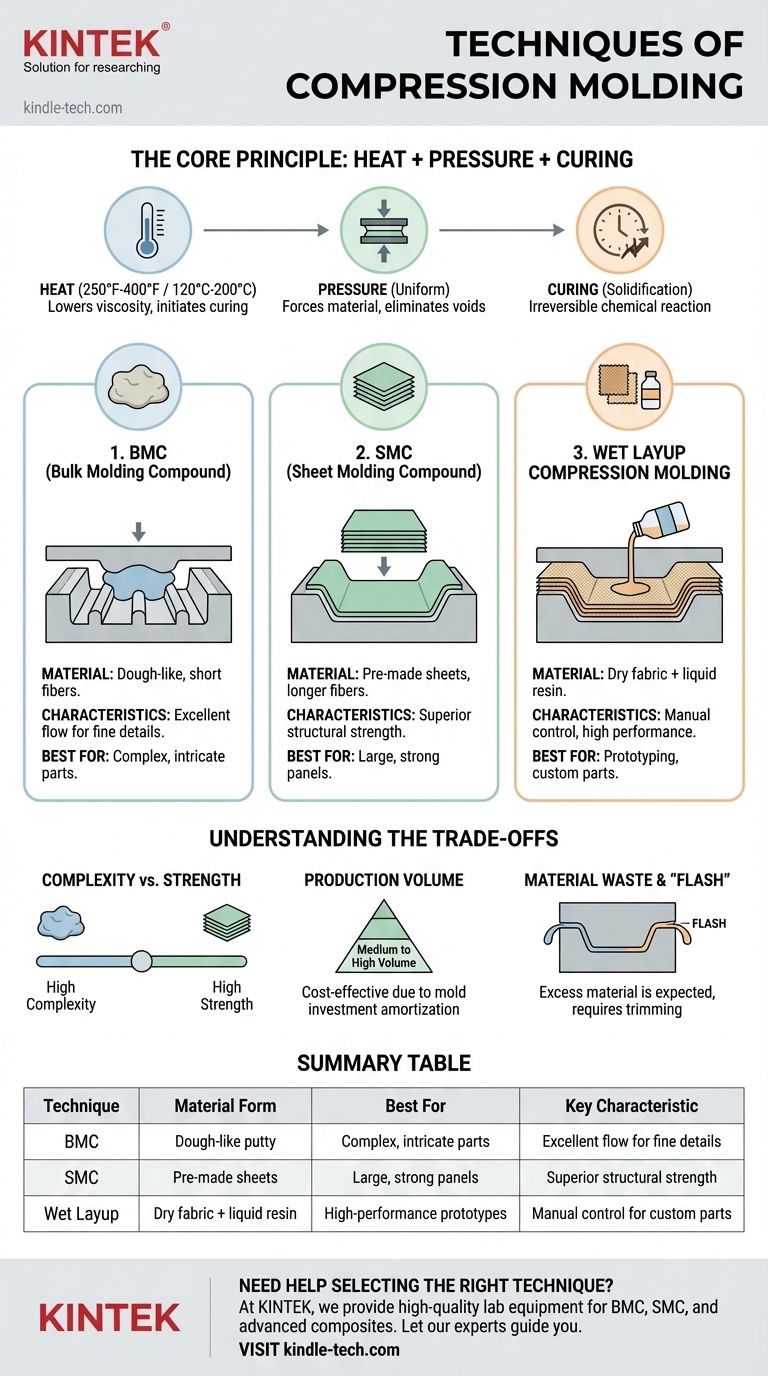

The primary techniques of compression molding are defined not by different machinery, but by the physical form of the composite material placed into the mold. The core process involves placing this material into a heated mold, which is then closed and subjected to intense pressure, forcing the material to fill the cavity and cure into a solid part. The specific technique chosen depends on the required strength, complexity, and production volume of the final component.

The critical distinction between compression molding techniques lies in the starting material: using a dough-like Bulk Molding Compound (BMC) for complex shapes, a pre-made Sheet Molding Compound (SMC) for large, strong panels, or a manual Wet Layup for bespoke, high-performance parts.

The Core Principle: Combining Heat and Pressure

Before examining specific techniques, it's essential to understand the fundamental process they all share. This process is designed for thermoset materials, which undergo an irreversible chemical reaction to harden.

The Role of Heat

The mold is heated to a precise temperature, typically between 250°F and 400°F (120°C to 200°C). This heat serves two purposes: it lowers the viscosity of the polymer resin, allowing it to flow, and it initiates the chemical cross-linking reaction (curing) that solidifies the part.

The Function of Pressure

Once the material is in the open mold cavity, a press closes the mold, applying significant and uniform pressure. This pressure forces the now-viscous material into every detail of the mold cavity, eliminates trapped air or gas, and ensures a dense, void-free final product.

The Curing Stage

The part is held under continuous heat and pressure for a set cycle time. During this phase, the thermoset resin cures completely, transforming from a pliable material into a hard, durable, and dimensionally stable component.

Key Techniques Defined by Material Form

The choice of material, or "charge," is what truly defines the technique and its suitability for a given application.

Technique 1: Bulk Molding Compound (BMC)

BMC is a dough-like, putty-like composite material. It consists of a thermoset resin (like polyester or vinyl ester) mixed with fillers, additives, and short chopped fibers (typically fiberglass).

This mixture is placed into the mold as a single lump or "charge." Its high flowability under pressure makes it ideal for producing parts with intricate details, ribs, and bosses.

Technique 2: Sheet Molding Compound (SMC)

SMC is a ready-to-mold, sheet-form composite material. It is manufactured by sandwiching chopped or continuous fiber strands between layers of resin paste, which is then compacted and matured over several days.

The operator cuts a pattern from the sheet and stacks the pieces in the mold. Because SMC often contains longer fibers than BMC, it provides superior structural strength, making it perfect for larger, flatter components like vehicle body panels and electrical enclosures.

Technique 3: Wet Layup Compression Molding

This is a more manual technique, often used for prototyping or low-volume production of high-performance parts. It involves placing dry reinforcement fabrics (like carbon fiber or fiberglass) into the mold.

A precise amount of liquid thermoset resin is then poured over the fabric. When the mold is closed, the pressure forces the resin to impregnate the fabric completely—a process known as Resin Transfer Molding (RTM) in its more advanced forms.

Understanding the Trade-offs

Each technique presents a unique balance of cost, performance, and design freedom. Making an informed decision requires understanding these compromises.

Complexity vs. Strength

There is a direct trade-off between a part's geometric complexity and its ultimate strength.

BMC excels at producing complex, three-dimensional parts with fine details but offers lower structural strength due to its short, randomly oriented fibers.

SMC delivers significantly higher strength and stiffness, making it ideal for structural applications, but it is less suited for filling very small or intricate features.

Tooling and Production Volume

Compression molding requires hardened steel molds capable of withstanding high temperatures and pressures. This tooling represents a significant upfront investment.

Consequently, the process is most cost-effective for medium to high production volumes, where the cost of the mold can be amortized over thousands of parts. It is generally not suitable for one-off or very low-volume production.

Material Waste and "Flash"

The process requires using slightly more material than is needed for the final part. This ensures the cavity is completely filled.

The excess material is squeezed out at the mold's parting line, creating a thin flange known as "flash." This flash is an expected byproduct and must be removed in a secondary trimming or finishing operation.

Selecting the Right Technique for Your Application

Your final choice depends entirely on the specific goals of your project.

- If your primary focus is intricate, complex shapes: BMC is the superior choice due to its excellent flow properties, which allow it to fill ribs, bosses, and tight corners with ease.

- If your primary focus is high structural strength and large surface areas: SMC is the ideal technique because its longer, integrated fiber reinforcement provides excellent stiffness and impact resistance for components like body panels.

- If your primary focus is maximum performance or low-volume prototypes: A wet layup approach gives you precise control over fiber type and orientation, making it suitable for aerospace or high-performance automotive parts where cost is secondary to performance.

Ultimately, understanding the form and properties of your starting material is the key to mastering the compression molding process.

Summary Table:

| Technique | Material Form | Best For | Key Characteristic |

|---|---|---|---|

| BMC (Bulk Molding Compound) | Dough-like putty | Complex, intricate parts | Excellent flow for fine details |

| SMC (Sheet Molding Compound) | Pre-made sheets | Large, strong panels | Superior structural strength |

| Wet Layup | Dry fabric + liquid resin | High-performance prototypes | Manual control for custom parts |

Need help selecting the right compression molding technique for your lab or production needs? At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your specific requirements—whether you're working with BMC, SMC, or advanced composites. Let our experts guide you to the ideal solution for strength, complexity, and efficiency. Contact us today to discuss your project!

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Infrared Heating Quantitative Flat Plate Press Mold

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Heat Press Machine

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

People Also Ask

- What is the function of a metal mold in cold press forming of Al2O3/ZrO2 ceramics? Achieve Precision Shaping

- What functions do Titanium plungers perform within solid-state battery molds? Optimize Pressure & Conductivity

- What is the core role of specialized pressurized battery test cell dies? Optimizing All-Solid-State Battery Testing

- Why are a laboratory hydraulic press and precision molds required for pressing MAX phase green bodies? - Expert Guide

- What functions do PTFE insulation sleeves serve in solid-state battery molds? Enhance Battery Assembly Precision

- What are the primary functions of a graphite mold coated with Boron Nitride (BN)? Optimize Sintering Quality

- What dual role does the graphite mold play during the hot-pressing sintering process of W-Si alloy targets?

- What are the primary functions of a stainless steel mold in CSP? Enhancing CaF2 Ceramic Densification