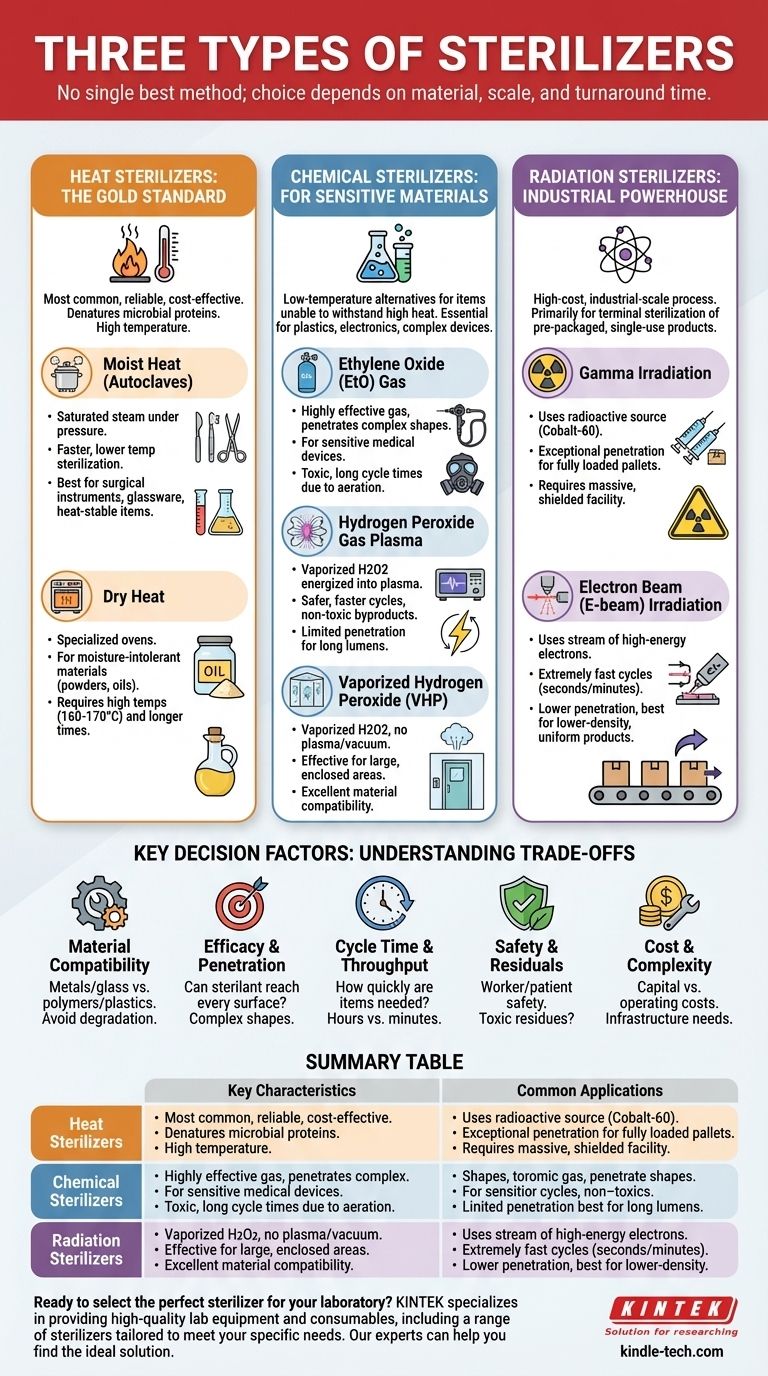

In sterilization, there is no single best method; the three primary categories of sterilizers are heat sterilizers (like autoclaves), low-temperature chemical sterilizers (using gas, plasma, or vapor), and radiation sterilizers (using gamma or electron beams). The ideal choice is determined not by the sterilizer itself, but by the material being sterilized, the scale of the operation, and the required turnaround time.

Choosing a sterilizer is a process of matching the method to the material. Heat is highly effective and non-toxic but can damage sensitive items. Chemical and radiation methods offer low-temperature alternatives but introduce their own complexities regarding safety, cost, and material compatibility.

Understanding Heat Sterilization: The Gold Standard

Heat sterilization is the most common, reliable, and cost-effective method for items that can withstand high temperatures and, in some cases, moisture. It works by denaturing the essential proteins of microorganisms.

Moist Heat (Autoclaves)

The autoclave is the most prevalent sterilizer in healthcare settings. It uses saturated steam under high pressure to achieve sterilization at lower temperatures and in shorter times than dry heat alone.

It is the preferred method for sterilizing most surgical instruments, glassware, and other durable, heat-stable items.

Dry Heat

Dry heat sterilizers are essentially specialized ovens. They are used for materials that cannot tolerate moisture, such as powders, oils, petroleum jellies, or items susceptible to rust.

This method requires significantly higher temperatures (e.g., 160-170°C) and much longer exposure times compared to autoclaving, as dry heat is less efficient at transferring energy than moist heat.

Navigating Chemical Sterilization: For Sensitive Materials

When items cannot withstand the high temperatures of heat sterilization, chemical methods provide a low-temperature alternative. These are essential for sterilizing plastics, electronics, and complex medical devices.

Ethylene Oxide (EtO) Gas

Ethylene oxide is a highly effective, low-temperature gas sterilant that can penetrate complex shapes and packaging materials. It is a go-to method for a vast range of sensitive medical devices.

However, EtO is a toxic and carcinogenic gas. The sterilization cycle is very long due to the need for extensive post-cycle aeration to remove residual gas, which can take many hours or even days.

Hydrogen Peroxide Gas Plasma

This method vaporizes hydrogen peroxide, which is then energized into a plasma state by an electromagnetic field. The resulting free radicals effectively kill microorganisms.

Gas plasma is much safer than EtO, with non-toxic byproducts (water and oxygen), and features significantly faster cycle times. Its main limitation is reduced penetration capability, making it unsuitable for long, narrow lumens, liquids, or powders.

Vaporized Hydrogen Peroxide (VHP)

Similar to gas plasma, VHP uses vaporized hydrogen peroxide but does not use a deep vacuum or plasma phase. It is highly effective for sterilizing large, enclosed areas like isolators, rooms, and pass-through chambers.

VHP has excellent material compatibility but, like plasma, has limitations with complex lumens and cellulose-based materials (paper).

Leveraging Radiation Sterilization: The Industrial Powerhouse

Radiation sterilization is a high-cost, industrial-scale process used almost exclusively for the terminal sterilization of pre-packaged, single-use products like sutures, syringes, and medical implants. It is not a method used within a typical hospital or clinic setting.

Gamma Irradiation

Gamma sterilization uses a radioactive source, typically Cobalt-60, to emit high-energy photons. It has exceptional penetration power, allowing it to sterilize fully loaded pallets of sealed products.

The process is continuous and highly reliable, but it requires a massive, shielded facility and involves handling radioactive materials.

Electron Beam (E-beam) Irradiation

E-beam sterilization uses a stream of high-energy electrons to sterilize products. The cycle time is extremely fast—measured in seconds or minutes—compared to the hours required for gamma.

However, the penetration power of e-beams is significantly lower than gamma rays, making it best suited for lower-density, uniformly packaged products.

Understanding the Trade-offs: Key Decision Factors

Your choice of sterilizer is a balance of competing factors. Overlooking any one of these can lead to material damage, ineffective sterilization, or operational bottlenecks.

Material Compatibility

This is the primary driver. Metals and glass can handle autoclaves. Polymers, plastics, and electronics require low-temperature chemical methods. Certain plastics can degrade or discolor when exposed to radiation.

Efficacy and Penetration

Can the sterilant reach every surface? Steam and EtO have excellent penetration for complex instruments with lumens. Gas plasma and radiation have more limitations in this area.

Cycle Time and Throughput

How quickly do you need the items back? A plasma sterilizer can process a load in under an hour. An EtO cycle, including aeration, can take over 12 hours. Autoclaves are fast and efficient for routine loads.

Safety and Residuals

Worker safety and patient safety are paramount. EtO is highly toxic and requires strict monitoring and handling protocols. Heat and plasma sterilization leave no toxic residues, making them inherently safer at the point of use.

Cost and Complexity

Autoclaves have a low capital cost and are inexpensive to operate (using distilled water and electricity). Low-temperature chemical sterilizers are more expensive to purchase and require proprietary consumables. Radiation facilities represent a multi-million dollar investment.

Making the Right Choice for Your Application

Your selection criteria should be guided by your most critical operational need and the nature of the items you are sterilizing.

- If your primary focus is sterilizing standard surgical and dental instruments: The autoclave (moist heat) is the most reliable, cost-effective, and validated method.

- If your primary focus is sterilizing heat- or moisture-sensitive devices like endoscopes, cameras, or certain plastics: Low-temperature chemical methods like Hydrogen Peroxide Gas Plasma are the modern standard for fast, safe turnaround.

- If your primary focus is a mix of sensitive devices, including some that are incompatible with plasma: Ethylene Oxide (EtO) remains a necessary, albeit complex, option for its broad material compatibility.

- If your primary focus is mass sterilization of single-use, pre-packaged products: Industrial radiation methods like Gamma or E-beam are the industry standard, typically managed through a specialized contract sterilizer.

Ultimately, a thorough understanding of your materials and processes is the foundation for effective and safe sterilization.

Summary Table:

| Sterilizer Type | Key Characteristics | Common Applications |

|---|---|---|

| Heat Sterilizers | High temperature, reliable, cost-effective | Surgical instruments, glassware, heat-stable items |

| Chemical Sterilizers | Low-temperature, uses gas/plasma/vapor | Endoscopes, electronics, moisture-sensitive devices |

| Radiation Sterilizers | Industrial-scale, high penetration | Single-use, pre-packaged products (sutures, syringes) |

Ready to select the perfect sterilizer for your laboratory?

KINTEK specializes in providing high-quality lab equipment and consumables, including a range of sterilizers tailored to meet your specific needs. Whether you require a reliable autoclave for your surgical instruments or a sophisticated low-temperature system for sensitive devices, our experts can help you find the ideal solution to ensure effective sterilization, operational efficiency, and safety.

Contact our team today to discuss your requirements and discover how KINTEK can support your laboratory's critical work.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- How does an autoclave ensure the reliability of experimental results? Achieving a Sterile Baseline for Lab Research

- How does a laboratory autoclave ensure the success of long-cycle continuous fermentation processes? Secure Pure Strains

- What types of items and materials can be processed in a laboratory autoclave? Essential Guide for Lab Safety

- Why is a laboratory autoclave necessary for Postgate Medium B (PMB)? Ensure Pure SRB Cultures & Accurate MIC Research