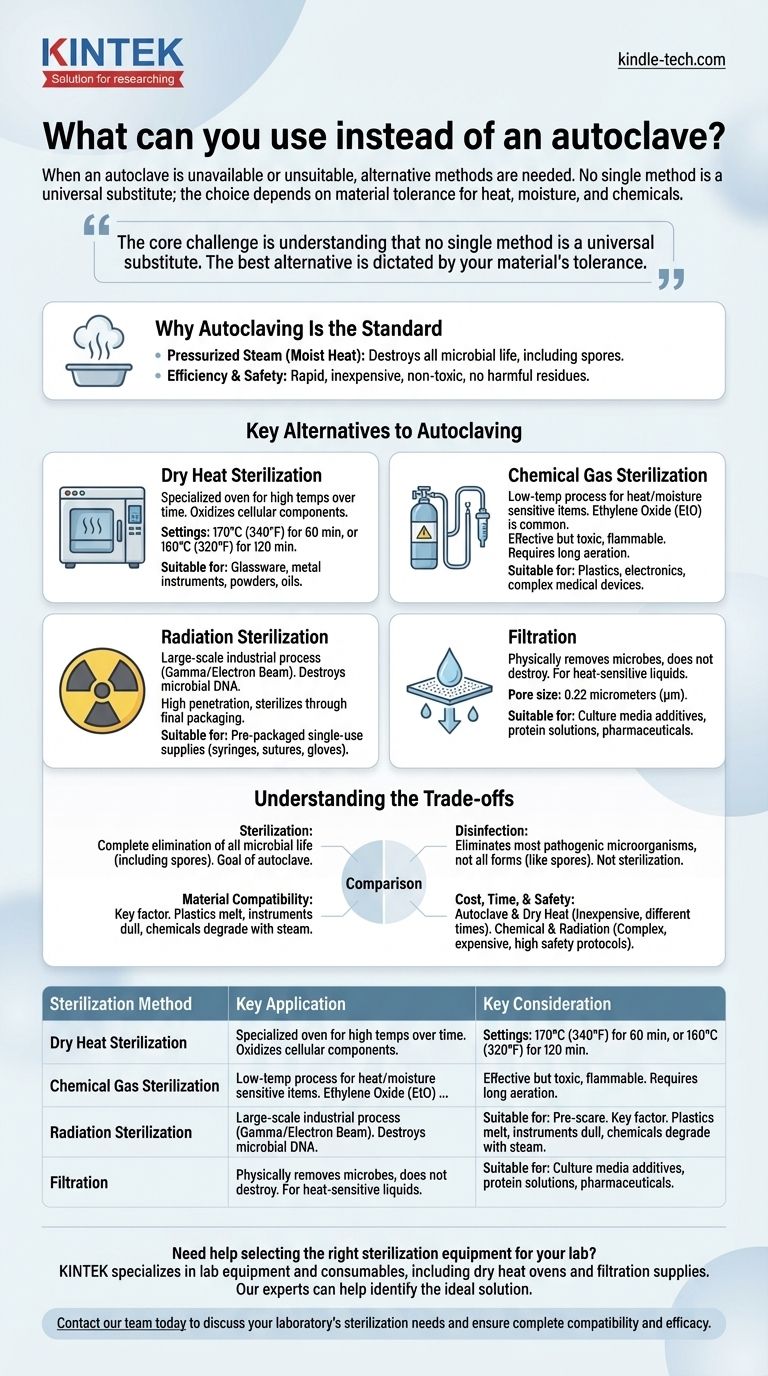

When an autoclave is unavailable or unsuitable, several alternative sterilization methods can be employed, each with specific applications. The most common alternatives include dry heat sterilization using an oven, chemical sterilization with gases like ethylene oxide, radiation, and filtration for heat-sensitive liquids. The choice of method depends entirely on the material being sterilized and the required level of sterility.

The core challenge is not finding a replacement for an autoclave, but rather understanding that no single method is a universal substitute. The best alternative is dictated by your material's tolerance for heat, moisture, and chemicals.

Why Autoclaving Is the Standard

Before exploring alternatives, it's crucial to understand why autoclaving is the benchmark for sterilization in medical and laboratory settings.

The Power of Pressurized Steam

An autoclave uses moist heat in the form of high-pressure steam. This combination is exceptionally effective at destroying all forms of microbial life, including resilient bacterial spores.

Efficiency and Safety

Steam is a highly efficient medium for heat transfer, allowing for rapid and thorough penetration of items. The process is also relatively fast, inexpensive, and non-toxic, leaving behind no harmful residues.

Key Alternatives to Autoclaving

When items are sensitive to the high heat, pressure, or moisture of an autoclave, one of the following methods is typically required.

Dry Heat Sterilization

This method uses a specialized oven to sterilize items with high temperatures over a prolonged period. It works by oxidizing cellular components.

Typical settings are 170°C (340°F) for 60 minutes or 160°C (320°F) for 120 minutes. Dry heat is suitable for materials that are damaged by moisture but can withstand high temperatures, such as glassware, metal instruments, powders, and oils.

Chemical Gas Sterilization

This low-temperature process is essential for delicate instruments and devices that cannot tolerate heat or moisture.

Ethylene Oxide (EtO) is a common gas used for this purpose. It is highly effective but also toxic and flammable, requiring specialized equipment and long aeration cycles to remove residual gas. It is a standard for sterilizing plastics, electronics, and other sensitive medical equipment.

Radiation Sterilization

This is a large-scale industrial process, not typically performed in a lab or clinic. It uses ionizing radiation (Gamma or Electron Beam) to destroy microbial DNA.

It is the preferred method for sterilizing pre-packaged, single-use medical supplies like syringes, sutures, and gloves. Its high penetration power ensures the sterility of products even within their final packaging.

Filtration

Filtration does not destroy microbes but physically removes them. It is the primary method for sterilizing heat-sensitive (heat-labile) liquids.

The liquid is passed through a filter with a pore size typically 0.22 micrometers (µm), which is small enough to trap bacteria. This is commonly used for sterilizing culture media additives, protein solutions, and pharmaceuticals.

Understanding the Trade-offs

Choosing an alternative involves balancing efficacy against material compatibility and safety. The most common mistake is confusing true sterilization with simple cleaning.

Sterilization vs. Disinfection

Sterilization, the goal of an autoclave, is the complete elimination of all microbial life, including spores.

Disinfection, by contrast, only eliminates most pathogenic microorganisms but not necessarily all microbial forms (like bacterial spores). Methods like boiling water or using chemical wipes are forms of disinfection, not sterilization.

Material Compatibility is Key

The primary reason to seek an autoclave alternative is material incompatibility. Plastics may melt, sharp instruments can dull, and certain chemicals or powders can be ruined by steam. Your material dictates your method.

Cost, Time, and Safety

Autoclaving is fast and has a low operational cost. Dry heat is also relatively inexpensive but takes much longer.

Chemical and radiation sterilization are far more complex, expensive, and involve significant safety protocols due to the hazardous materials or radiation sources required.

Selecting the Right Method for Your Material

Your choice must be driven by the item you need to sterilize and the resources you have available.

- If your primary focus is sterilizing heat-sensitive liquids like media supplements or drugs: Filtration is the correct and most accessible method.

- If your primary focus is sterilizing glassware, metal instruments, or anhydrous oils: A dry heat oven is a perfectly suitable and common alternative to an autoclave.

- If your primary focus is sterilizing complex medical devices, plastics, or electronics: Industrial-scale chemical gas (EtO) or radiation sterilization is required; these are not typically in-house procedures.

- If your primary focus is simply reducing pathogens on a non-critical surface: High-level disinfection may be sufficient, but do not mistake this for achieving true sterility.

Choosing the correct sterilization method is about matching the unique properties of your material to the proven capabilities of the technique.

Summary Table:

| Sterilization Method | Key Application | Key Consideration |

|---|---|---|

| Dry Heat Oven | Glassware, metal instruments, powders, oils | Requires high temperatures (160-170°C) for 1-2 hours |

| Chemical Gas (e.g., EtO) | Plastics, electronics, complex medical devices | Involves toxic gases and long aeration cycles |

| Radiation (Gamma/e-beam) | Pre-packaged single-use medical supplies | Industrial-scale process, not for in-house use |

| Filtration (0.22 µm) | Heat-sensitive liquids (media, pharmaceuticals) | Physically removes bacteria but does not destroy them |

Need help selecting the right sterilization equipment for your lab?

Choosing the correct method is critical for both material integrity and safety. KINTEK specializes in lab equipment and consumables, including ovens for dry heat sterilization and filtration supplies. Our experts can help you identify the ideal solution for your specific materials and workflow.

Contact our team today to discuss your laboratory's sterilization needs and ensure complete compatibility and efficacy.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility

- What is a lab autoclave? Your Guide to Sterilization with Pressurized Steam

- How does the lab autoclave work? Achieve Complete Sterilization with High-Pressure Steam

- What are the sizes of autoclaves? A Guide to Choosing the Right Capacity for Your Lab

- Do you need to autoclave glassware? A Guide to Sterilization vs. Cleaning