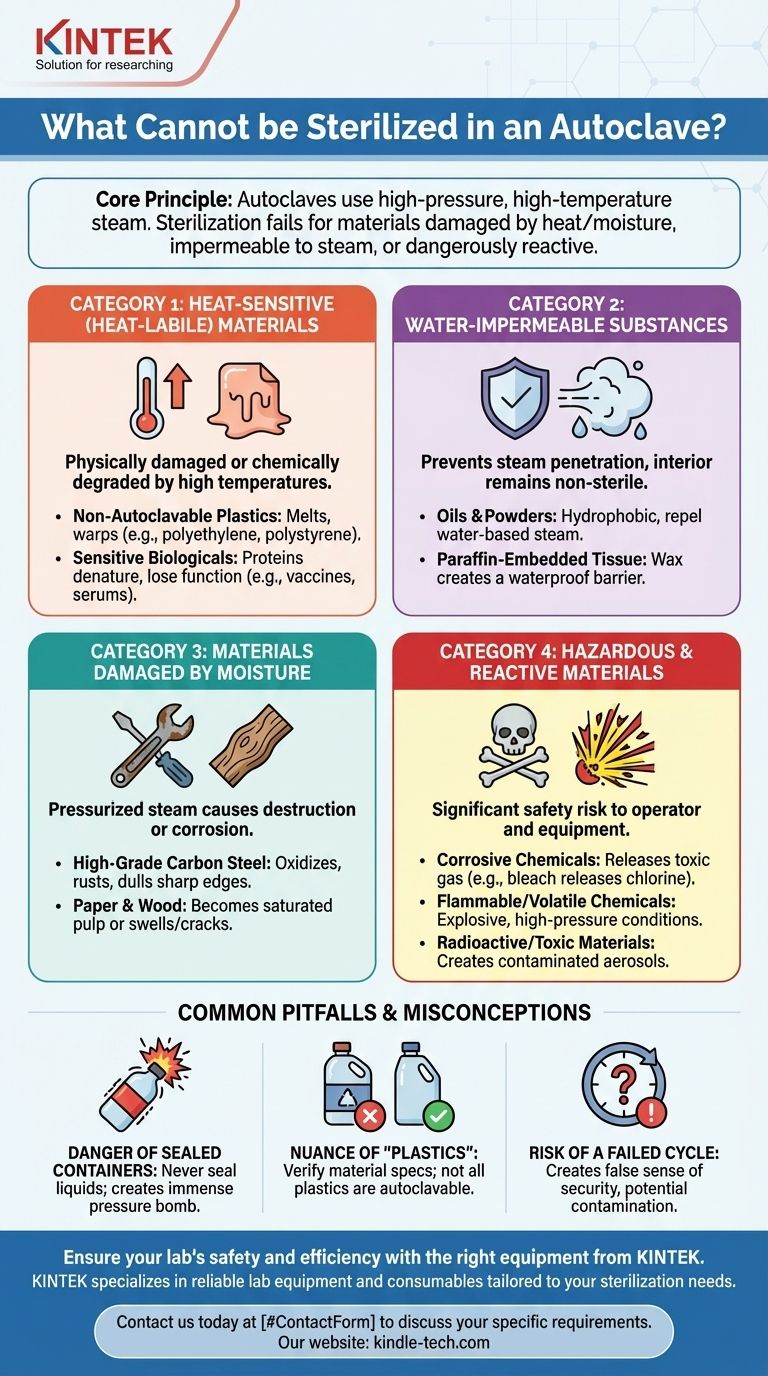

Fundamentally, an autoclave cannot sterilize any material that is damaged by heat and moisture, impermeable to steam, or dangerously reactive under pressure. This includes most non-autoclavable plastics which will melt, oily or powdered substances that block steam penetration, and corrosive chemicals like bleach which can release toxic gas. Sharp instruments made of high-grade carbon steel will also be dulled by the high-temperature steam.

The power of an autoclave—its use of high-pressure, high-temperature steam—is also its primary limitation. Effective sterilization is entirely dependent on direct steam contact and a material's ability to withstand it; anything that blocks steam or degrades under heat and moisture will fail or create a hazard.

The Principle of Steam Sterilization

An autoclave does not sterilize with dry heat alone. It works by creating a high-pressure environment that allows steam to reach temperatures far above boiling, typically 121°C (250°F) or higher.

The Need for Direct Contact

This superheated steam must make direct contact with every surface of the item being sterilized. The moisture in the steam is the agent that efficiently transfers lethal heat, denaturing proteins and killing microorganisms.

Why This Mechanism Matters

If steam cannot touch a surface, that surface will not be sterilized. This core principle explains why certain categories of materials are fundamentally incompatible with autoclaving.

Materials Unsuitable for an Autoclave

Based on this principle, we can group incompatible materials into clear categories based on why they fail the autoclaving process.

Category 1: Heat-Sensitive (Heat-Labile) Materials

These materials are physically damaged or chemically degraded by the high temperatures.

- Non-Autoclavable Plastics: Many common plastics, like polyethylene and polystyrene, have low melting points and will warp or melt into a useless puddle, potentially damaging the autoclave itself. Always check for an "autoclavable" rating.

- Sensitive Biologicals: High-protein solutions, certain vaccines, and serums cannot be autoclaved. The intense heat will denature the proteins, destroying their biological function and rendering them useless.

Category 2: Water-Impermeable Substances

These materials prevent the penetration of steam, leaving the bulk of the substance unsterilized.

- Oils and Powders: Oily substances are hydrophobic and repel the water-based steam. Similarly, powders are so dense that steam cannot penetrate the bulk material. While the surface may get hot, the interior remains non-sterile.

- Paraffin-Embedded Tissue: The wax creates a waterproof barrier, shielding the embedded tissue from the steam and preventing sterilization.

Category 3: Materials Damaged by Moisture

Even if a material can withstand the heat, the presence of pressurized steam can be destructive.

- High-Grade Carbon Steel: Sharp instruments like certain scalpels and scissors are often made of carbon steel. The high-temperature moisture will cause oxidation, which dulls the fine cutting edge and promotes rust. Stainless steel instruments, however, are generally safe to autoclave.

- Paper and Wood: Paper products will become a saturated, useless pulp. Wood can swell and crack.

Category 4: Hazardous and Reactive Materials

Placing these items in an autoclave poses a significant safety risk to both the operator and the equipment.

- Corrosive Chemicals: Never autoclave household bleach. The heat and pressure will cause it to release toxic chlorine gas. Other corrosives can damage the stainless steel chamber of the autoclave.

- Flammable or Volatile Chemicals: Solvents and other volatile substances can create explosive, high-pressure conditions inside the chamber.

- Radioactive or Toxic Materials: Autoclaving these materials can create contaminated aerosols, spreading the hazardous substance through the air when the autoclave is opened.

Common Pitfalls and Misconceptions

Understanding what not to autoclave is only half the battle. Avoiding common user errors is just as critical for safety and success.

The Danger of Sealed Containers

Never autoclave a liquid in a tightly sealed container. As the liquid heats up, it will expand and create immense pressure, turning the container into a bomb that can explode inside the chamber. Always ensure caps are loosened to allow for pressure equalization.

The Nuance of "Plastics"

The term "plastic" is too broad. Polypropylene (PP) and some polycarbonates (PC) are often autoclavable, while low-density polyethylene (LDPE) and polystyrene (PS) are not. Always verify the material's specifications or look for the "autoclavable" symbol.

The Risk of a Failed Cycle

Placing an unsuitable item in an autoclave, like a vial of powder, doesn't just mean that one item isn't sterile. It creates a false sense of security that can lead to critical contamination in your subsequent work. An item that has been through a failed cycle is more dangerous than one known to be non-sterile.

Making the Right Choice for Your Goal

Your sterilization method must match your material and your objective.

- If your primary focus is sterility for liquids or durable labware: The autoclave is your gold standard, provided materials are heat and moisture stable like glassware, stainless steel, and rated plastics.

- If you are working with heat-sensitive materials: You must use an alternative like filtration for liquids or a chemical sterilant (e.g., ethylene oxide gas) for solid items.

- If you are handling oils, powders, or water-free substances: Dry heat sterilization in an oven is the appropriate method, as it relies on conduction rather than steam penetration.

- If safety is your main concern: Never autoclave flammable, corrosive, or unknown chemicals; consult your institution's safety protocols for proper decontamination and disposal.

Understanding the autoclave's reliance on pressurized steam is the key to using it safely and effectively.

Summary Table:

| Material Category | Examples | Reason for Incompatibility |

|---|---|---|

| Heat-Sensitive Materials | Non-autoclavable plastics (polyethylene), sensitive biologicals | Melts, warps, or denatures at high temperatures |

| Water-Impermeable Substances | Oils, powders, paraffin-embedded tissue | Blocks steam penetration, preventing sterilization |

| Moisture-Sensitive Items | High-grade carbon steel instruments, paper, wood | Causes oxidation, rust, swelling, or structural damage |

| Hazardous/Reactive Materials | Bleach, flammable solvents, radioactive substances | Releases toxic gases, creates explosion risks, or spreads contamination |

Ensure your lab's safety and efficiency with the right equipment from KINTEK.

Autoclaving the wrong materials can lead to equipment damage, safety hazards, and compromised results. KINTEK specializes in providing reliable lab equipment and consumables tailored to your sterilization needs—whether you require autoclaves for heat-stable items or alternative solutions for sensitive materials.

Contact us today at [#ContactForm] to discuss your specific requirements. Our experts will help you select the ideal products to maintain sterility, protect your instruments, and enhance your laboratory workflows.

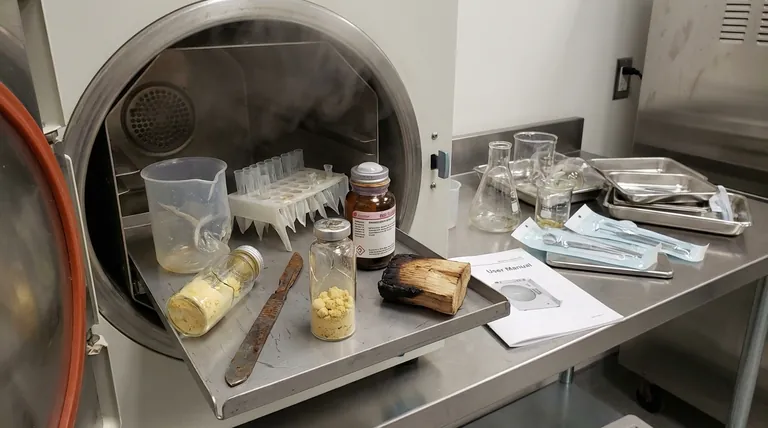

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- What can't be sterilized in an autoclave? Avoid Damaging Heat-Sensitive Materials

- What are the three components of autoclaving? Master the Phases for Perfect Sterilization

- What are the safety concerns of autoclave? Managing Heat, Pressure, and Steam Risks

- What is an autoclave laboratory equipment? The Ultimate Guide to Steam Sterilization

- Why is autoclave pressure 15 psi? The Key to Achieving Sterilizing Temperatures

- Why is it important that high temperatures are used in sterilisation? Ensure Complete Microbial Destruction

- What are the different types of autoclaves in microbiology? Gravity vs. Pre-Vacuum Explained

- What are the advantages of using an autoclave in the lab? Achieve Unmatched Sterilization for Your Lab