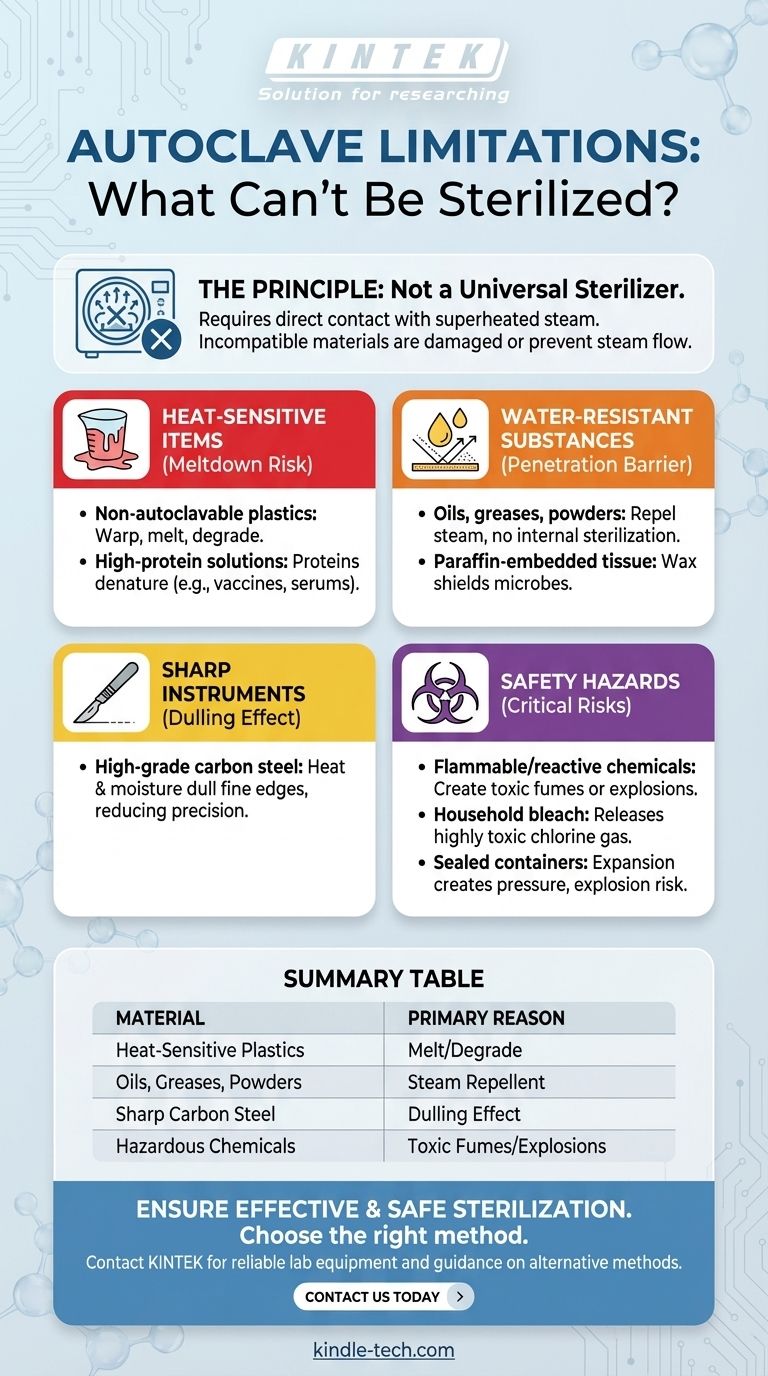

In short, an autoclave is not a universal sterilizer. It cannot be used for any material that is damaged by high heat and moisture, is impenetrable to steam, or poses a safety risk under high pressure and temperature. This includes heat-sensitive plastics, water-repellent substances like oils and powders, sharp high-grade carbon steel instruments, and volatile or corrosive chemicals like bleach.

The effectiveness of an autoclave hinges entirely on its use of high-pressure, superheated steam. Any material that is damaged by heat and moisture, or that physically prevents steam from making direct contact with every surface, is fundamentally incompatible with this method.

The Core Principle: Sterilization by Steam

An autoclave is essentially a highly sophisticated pressure cooker. It uses steam under pressure to achieve temperatures far beyond the boiling point of water, which is necessary to reliably kill microorganisms, including resilient bacterial spores.

How Pressure Creates Sterilizing Heat

By increasing the pressure inside its chamber, an autoclave raises the boiling point of water. For example, at a pressure of 108 kPa (approx. 15 PSI above atmospheric), steam reaches 121°C. At 206 kPa, it reaches 134°C. This superheated steam is the sterilizing agent.

The Necessity of Direct Contact

For sterilization to be successful, this hot, pressurized steam must make direct contact with every surface of the item being processed. If steam cannot penetrate or touch a surface, that surface will not be sterilized, regardless of the cycle's time or temperature.

Incompatible Materials: A Deeper Look

Understanding the principle of steam contact makes it clear why certain categories of materials are unsuitable for autoclaving.

Heat-Sensitive Items (The Meltdown Risk)

Many common materials simply cannot withstand the intense heat.

- Non-autoclavable plastics will warp, melt, or degrade, rendering them useless.

- High-protein solutions, such as vaccines, serums, or certain growth factors, will denature. The heat effectively "cooks" the proteins, destroying their biological function.

Water-Resistant Substances (The Penetration Barrier)

Steam is water. Therefore, any substance that repels water cannot be effectively sterilized by steam.

- Oils, greases, and powders are not water-miscible. The steam cannot penetrate the substance, leaving the interior completely unsterilized.

- Paraffin-embedded tissue is another key example where the waterproof wax shields any embedded microbes from the steam.

Sharp-Edged Instruments (The Dulling Effect)

While many surgical instruments are autoclaved, very sharp instruments made of high-grade carbon steel are an exception. The combination of high heat and moisture can dull the fine cutting edge, reducing the instrument's precision and effectiveness.

Common Pitfalls and Safety Hazards

Attempting to autoclave unsuitable materials is not just ineffective; it can be extremely dangerous.

Never Autoclave Hazardous Chemicals

This is a critical safety rule. The high heat and pressure can cause dangerous reactions.

- Flammable, reactive, or corrosive materials can create toxic fumes or cause an explosion.

- Household bleach (sodium hypochlorite) will release highly toxic chlorine gas when heated.

- Radioactive or toxic materials should never be autoclaved, as this can create hazardous aerosols.

Improper Loading Obstructs Steam Flow

Even with suitable materials, improper loading can cause a cycle to fail. Overpacking the chamber or using sealed containers prevents steam from circulating and making the necessary direct contact with all surfaces.

Sealed Containers Are Explosion Risks

Never place a tightly sealed container in an autoclave. As the liquid inside heats up, it will expand and create immense pressure, turning the container into a potential bomb. Caps must always be loosened to allow pressure to equalize.

Making the Right Choice for Your Goal

Selecting the correct sterilization method requires understanding your material and your objective.

- If your primary focus is sterilizing culture media, aqueous solutions, or durable labware (borosilicate glass, stainless steel): The autoclave is the most effective and reliable method.

- If your primary focus is handling heat-sensitive plastics or biologicals: You must use an alternative "cold" sterilization method, such as filtration, chemical sterilization (e.g., ethylene oxide), or irradiation.

- If your primary focus is processing oils, powders, or protecting sharp instruments: Dry heat sterilization is the appropriate choice, as it sterilizes without using moisture.

- If your primary focus is decontaminating biohazardous waste: The autoclave is ideal, provided you have removed any incompatible chemicals like bleach from the waste stream first.

Understanding these fundamental principles ensures both effective sterilization and the safety of your equipment and personnel.

Summary Table:

| Incompatible Material | Primary Reason for Incompatibility |

|---|---|

| Heat-Sensitive Plastics | Warp, melt, or degrade at high temperatures |

| Oils, Greases, Powders | Steam cannot penetrate water-repellent substances |

| Sharp Carbon Steel Instruments | High heat and moisture can dull the cutting edge |

| Hazardous Chemicals (e.g., Bleach) | Risk of toxic fumes, explosions, or corrosion |

| High-Protein Solutions (e.g., Vaccines) | Proteins denature and lose biological function |

Ensure your lab's sterilization is both effective and safe. Choosing the right equipment is critical for protecting your samples and instruments. KINTEK specializes in providing reliable lab equipment and consumables tailored to your specific sterilization needs. Whether you require autoclaves for aqueous solutions or guidance on alternative methods for heat-sensitive materials, our experts are here to help. Contact us today to find the perfect solution for your laboratory!

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What types of items and materials can be processed in a laboratory autoclave? Essential Guide for Lab Safety

- Why is the standard autoclave temperature set to 121? The Science of Effective Sterilization

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What is the life expectancy of an autoclave machine? Maximize Your Investment with Proper Care