At its core, a furnace pressure switch is a critical safety device. Its job is to verify that your furnace's exhaust system is clear and working correctly before allowing the burners to ignite. It does this by detecting a specific amount of negative pressure created by the draft inducer motor, ensuring a clear path for dangerous gases like carbon monoxide to be vented safely outside your home.

A furnace doesn't just produce heat; it produces toxic exhaust as a byproduct. The pressure switch acts as a gatekeeper, refusing to let the furnace operate until it can prove that this exhaust has a safe and unobstructed exit path.

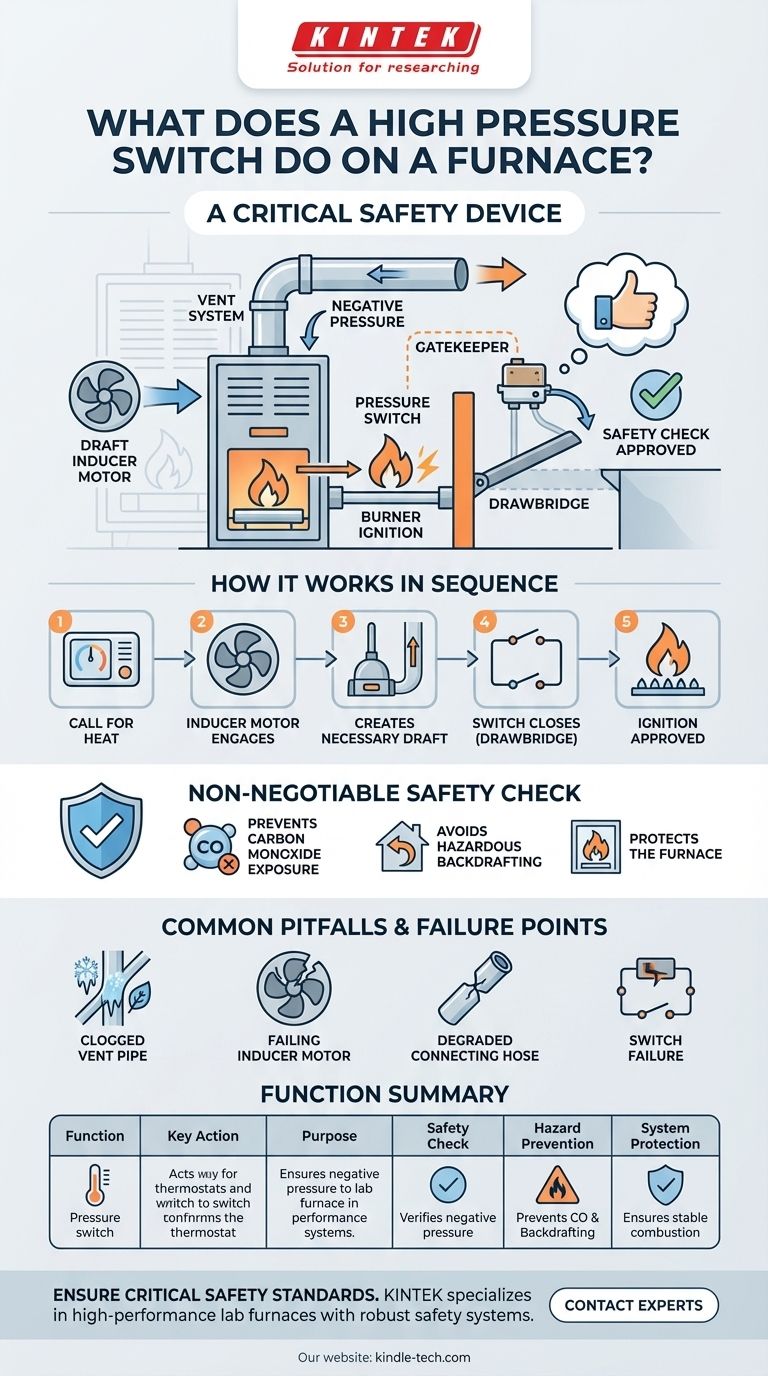

How the Pressure Switch Works in Sequence

A furnace doesn't simply turn on. It follows a precise startup sequence, and the pressure switch plays a pivotal role early in that process. Understanding this sequence reveals why the switch is so important.

The Call for Heat

It begins when your thermostat signals the furnace to start a heating cycle. This is the initial command that sets the entire chain of events in motion.

The Draft Inducer Motor Engages

Before any gas is released or ignited, the first mechanical component to activate is the draft inducer motor. This is a small fan designed to pull air through the heat exchanger and push it out the exhaust vent.

Creating the Necessary Draft

The action of the draft inducer motor creates a slight vacuum, or negative pressure, within the sealed venting system. This proves that the flue pipe is not blocked by snow, animal nests, or other debris.

The "Drawbridge" Closes

The pressure switch is connected to this system by a small rubber hose. When it senses the correct negative pressure, it closes an internal electrical contact. Think of it as a drawbridge: electricity is waiting on one side, and the switch closing lowers the bridge, allowing power to cross to the next component in the sequence.

Ignition is Approved

Only after the furnace's control board receives the signal that the pressure switch has closed will it proceed to the next steps: opening the gas valve and igniting the burners. If the switch never closes, the ignition sequence is aborted, and the furnace will not light.

Why This Safety Check is Non-Negotiable

A furnace that runs with a blocked vent is a serious hazard. The pressure switch is the primary defense against several dangerous scenarios.

Preventing Carbon Monoxide Exposure

This is the most critical function. If the vent is blocked, the furnace's primary byproduct, carbon monoxide (CO), has nowhere to go. A functioning pressure switch will prevent the furnace from even creating this gas by halting the ignition process.

Avoiding Hazardous Backdrafting

Backdrafting is what happens when exhaust fumes are pulled back into your home or furnace system instead of being expelled outside. This can introduce CO into your living space and also disrupt the stable combustion inside the furnace.

Protecting the Furnace Itself

Improperly vented hot gas can lead to "flame rollout," where flames exit the designated combustion chamber. This can damage internal components, melt wires, and create a significant fire hazard. The pressure switch helps ensure combustion remains stable and contained.

Common Pitfalls and Failure Points

When a furnace reports a pressure switch error, it is often a symptom of another problem. The switch itself is a simple component; the issue is frequently found elsewhere in the system.

A Clogged Vent Pipe

This is the most common cause. The pressure switch is simply doing its job by detecting a blockage in the intake or exhaust flue pipes outside your home. Snow, ice, leaves, or animal nests are frequent culprits.

A Failing Draft Inducer Motor

If the motor is weak or failing, it may not spin fast enough to generate the required negative pressure. The switch will not close, correctly identifying that the system cannot vent properly.

A Degraded Connecting Hose

The small rubber hose that connects the pressure switch to the draft assembly can become brittle, cracked, or clogged with debris over time. A leak in this hose will prevent the switch from sensing the correct pressure.

The Switch Itself Has Failed

While less common, the switch can fail. It might get stuck in the "open" position, preventing the furnace from ever starting, or it can get stuck "closed," creating a dangerous condition where the furnace might fire with a blocked vent. This is why control boards perform checks to ensure the switch is open before the cycle starts.

Making the Right Choice for Your Goal

A pressure switch fault code is a diagnostic clue, not an automatic diagnosis of the switch itself. Your response should be measured and prioritize safety.

- If your primary focus is immediate safety: Your first step should be to check the exterior PVC vent pipes for any obvious blockages like snow, ice, or debris.

- If you are a homeowner comfortable with basic observation: You can safely turn off the power to the furnace and visually inspect the small rubber hose connected to the switch for cracks or clogs.

- If the problem is not immediately obvious: This is the point to call a qualified HVAC technician. They have the tools to measure pressure and test circuits to accurately diagnose whether the fault lies with the switch, the motor, or a blockage.

Ultimately, understanding the pressure switch transforms it from a mysterious part into a logical and essential guardian of your home's heating system.

Summary Table:

| Function | Key Action | Purpose |

|---|---|---|

| Safety Check | Verifies draft inducer motor creates negative pressure | Ensures exhaust vent is clear before ignition |

| Hazard Prevention | Halts ignition sequence if pressure is incorrect | Prevents carbon monoxide exposure and backdrafting |

| System Protection | Ensures stable combustion | Protects furnace from damage and flame rollout |

Ensure your lab's heating equipment operates with the same critical safety standards. KINTEK specializes in high-performance lab furnaces and ovens, featuring robust safety systems for precise, reliable, and secure thermal processing. If your laboratory requires equipment that prioritizes safety and performance, contact our experts today to find the perfect solution for your needs.

Visual Guide

Related Products

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the role of zirconia fiber felt in Si2N2O synthesis? Ensuring Thermal Efficiency and Electrical Safety

- What is optical quartz? The Ultimate Material for UV and High-Temp Optics

- Why are quartz sleeves utilized to protect thermocouples during high-temperature corrosion testing? Ensure Data Accuracy

- What is the role of stainless steel ball milling jars and grinding balls in the mechanochemical synthesis of Li3P or Li3N?

- What is the role of high-temperature stainless steel fixtures in diffusion couple experiments? Ensure Data Integrity

- Why are pressure switches important? Essential for Automation, Safety & Efficiency

- Why is the use of high-grade corrosion-resistant lab equipment essential? Ensure Safety & Biomass Data Integrity

- Why is a liquid nitrogen cold trap installed at the reactor outlet? Essential Sample Preservation & System Protection